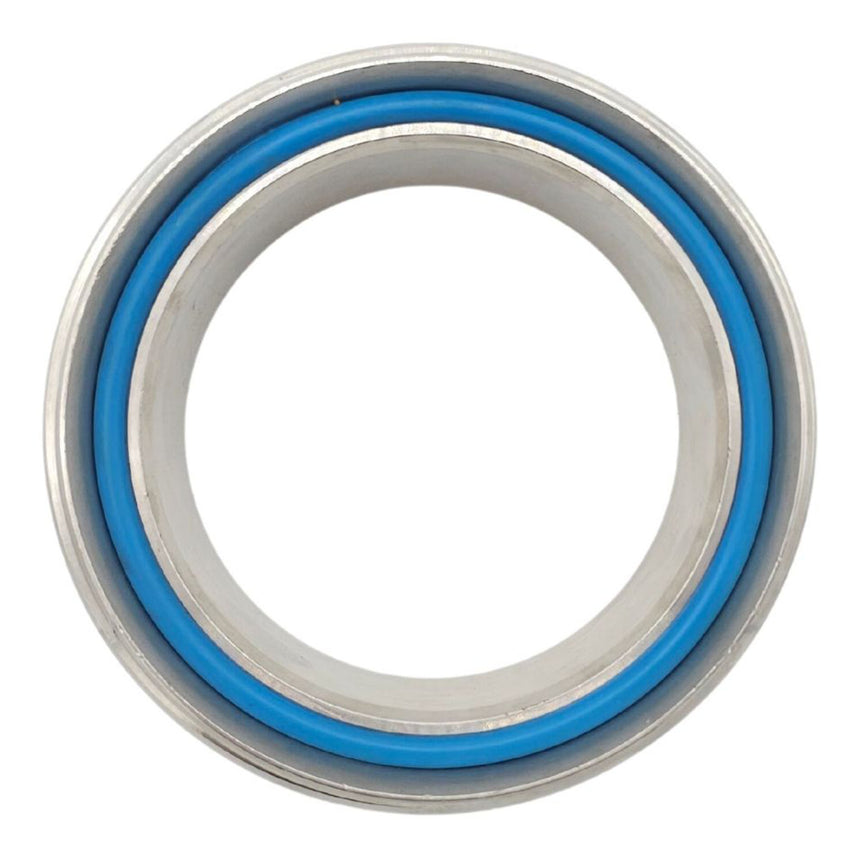

DIN 11851 Male Coupling to Weld Liner (Stainless Steel)

Couldn't load pickup availability

Get in Touch

Get in Touch

If you prefer to speak to someone directly, you can reach us via phone during our business hours. Simply dial 01406 362978, and one of our knowledgeable representatives will be ready to assist you.

Alternatively you can send us your query or request to sales@jmlhenderson.co.uk, and we will respond to you as promptly as possible.

Delivery

Delivery

When placing your order with us, rest assured that your items will be promptly shipped out using tracked, fastest-day delivery services. We prioritize efficient handling and secure shipping to ensure your package arrives swiftly and safely. Your satisfaction is our priority, and we strive to provide a seamless delivery experience from checkout to your doorstep.

FAQ

FAQ

Have questions? Check out our FAQ page for more information on a wide range of topics, from shipping and returns to product details and customer service inquiries. Click here to visit our FAQ page and find answers to commonly asked questions: FAQ Page. We're here to help make your shopping experience as smooth as possible.

A DIN 11851 Coupling Male Weld Liner is an essential component used in sanitary fluid handling systems, particularly in industries such as food and beverage, dairy, and pharmaceuticals where maintaining hygienic connections is crucial. This weld liner is designed to be permanently welded into a pipe or vessel, providing a sanitary connection point for a DIN 11851 male coupling.

Constructed from high-quality stainless steel, the DIN 11851 Male Weld Liner offers excellent durability, corrosion resistance, and ease of cleaning. Stainless steel is the preferred material in these environments because it can withstand the rigorous demands of frequent cleaning, exposure to chemicals, and high temperatures, ensuring that the weld liner maintains its integrity and sanitary standards over time.

The primary function of the DIN 11851 Male Weld Liner is to create a permanent, hygienic connection point within a piping system. Once welded into place, the liner serves as the interface between the pipe or tank and the DIN 11851 male coupling, providing a smooth, sanitary surface that minimizes the risk of contamination. This is especially important in industries where the cleanliness of the fluid being handled is critical to the quality of the final product.

The weld liner is designed to mate seamlessly with a corresponding DIN 11851 female coupling, ensuring a secure and leak-proof connection. The DIN 11851 standard is widely recognized for its ability to create tight seals that prevent leaks and maintain the purity of the fluid being transferred. The weld liner supports this by providing a robust and reliable attachment point that enhances the overall durability and hygiene of the system.

-

ProductDIN 11851

-

TypeDIN 11851 Weld On

-

Connection 1

-

Connection 2

-

Material Type

-

Colour

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.