- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

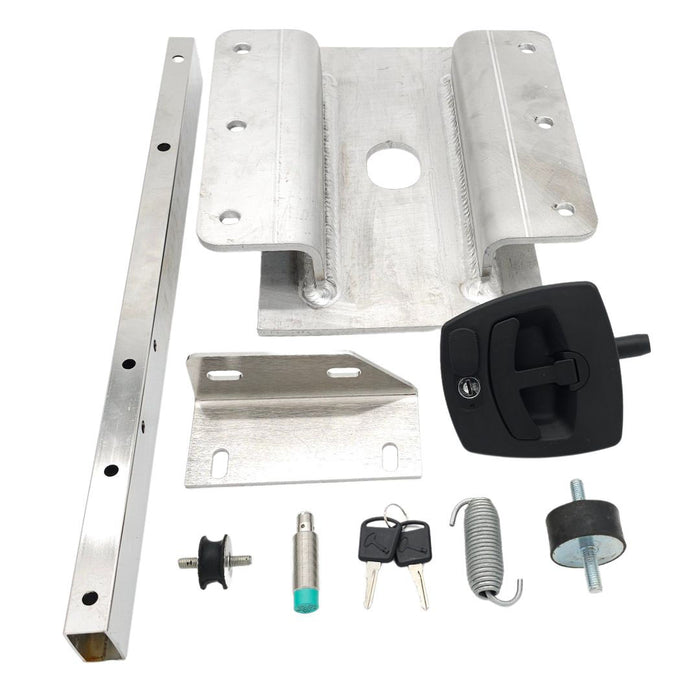

Hose carrier blanks are practical accessories designed to securely seal the open ends of hose carrier tubes, providing a reliable closure for storage and transport systems. These blanks are essential for keeping hoses protected from dust, debris, and environmental damage when the carrier is not in use. Widely used in industries such as firefighting, agriculture, and construction, hose carrier blanks are critical for maintaining hose integrity and ensuring they remain in optimal condition for immediate deployment. Available in sizes to fit 160mm, 180mm, and 200mm internal diameter (ID) tubes, they are a versatile solution for diverse operational needs.

Made from durable plastic, hose carrier blanks are lightweight, corrosion-resistant, and robust enough to withstand the rigors of demanding environments. The plastic construction ensures long-term performance with minimal maintenance, offering a cost-effective solution for protecting hoses during transport or storage. Available in single and double blank configurations, these closures cater to a range of requirements. Single blanks are straightforward and easy to install, while double blanks provide added security and are particularly useful for larger carrier tubes or extended storage needs.

Hose carrier blanks are designed for ease of use, featuring secure latching or push-fit mechanisms to keep them firmly in place, preventing accidental dislodgment. Their precision engineering ensures a snug fit, creating a reliable seal that protects hoses from moisture, dirt, and other external contaminants. Simple to install and replace, they enhance the efficiency and safety of hose storage systems. By offering multiple sizes and configurations, plastic hose carrier blanks provide a practical and reliable solution for professionals looking to optimize the protection and longevity of their hose equipment.Interested in a Quote?

Advantages of Using Hose Carrier Blank Ends

-

Protection Against Contaminants

-

Enhanced Safety

-

Securing Hoses and Cables

-

Improved Aesthetics

-

Extended Equipment Life

-

Noise Reduction