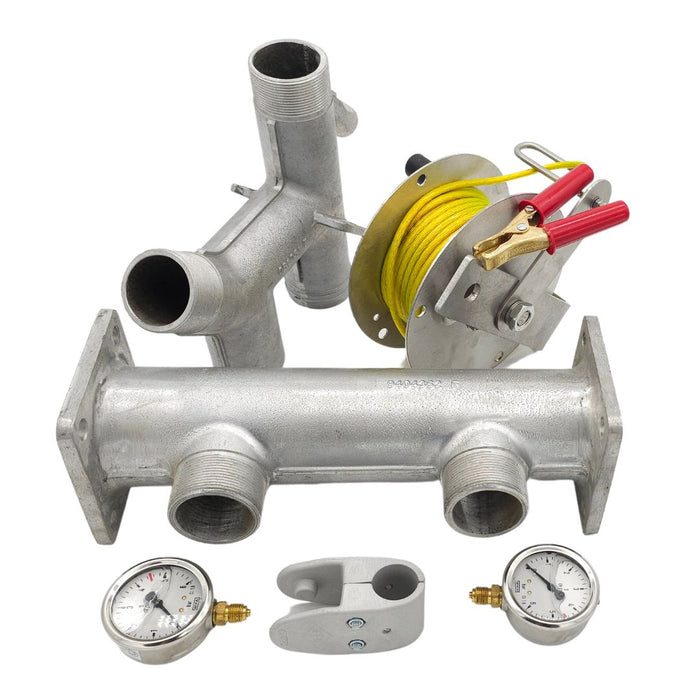

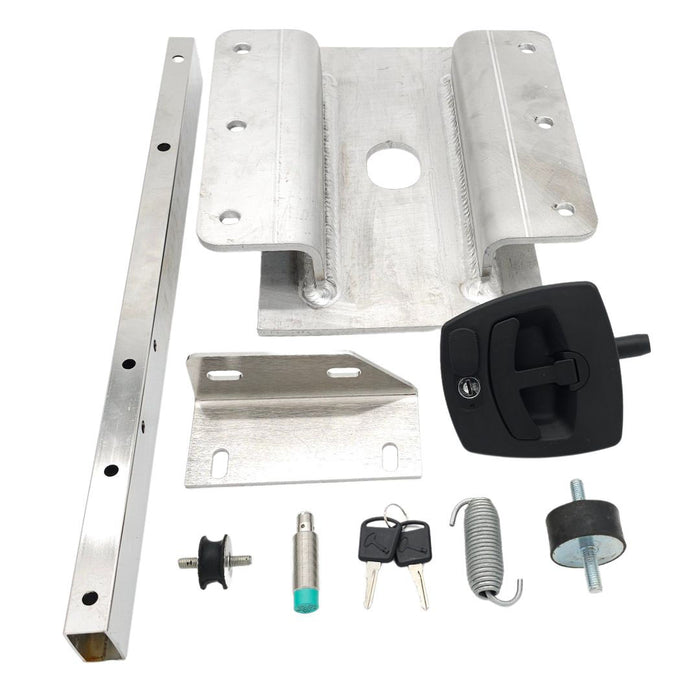

AKO Pinch Valve VT (Aluminium)

Regular price £0.00Unit price /Unavailable- Regular price £0.01Unit price /Unavailable

- Regular price £0.00Unit price /Unavailable

BSP Female AKO Pinch Valve VMC050

Regular price £0.00Unit price /Unavailable- Regular price £0.01Unit price /Unavailable

Wabco 3 / 2 Way Pinch Valve Switch

Regular price £0.00Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

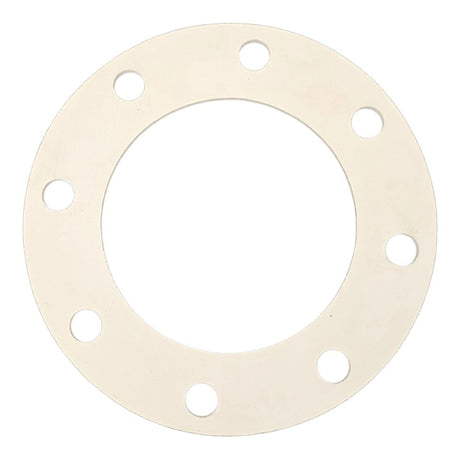

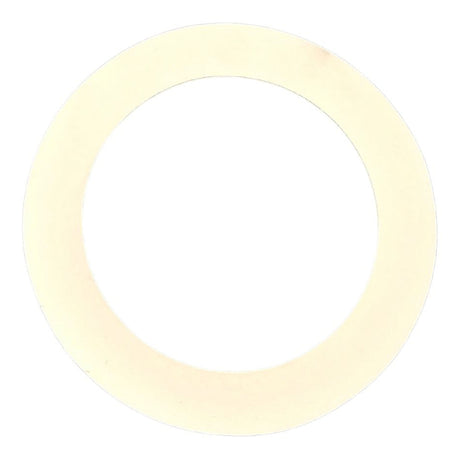

Mission Valve Flange Gasket (Rubber)

Regular price £0.00Unit price /Unavailable

Pinch valves are innovative flow control devices that use a flexible tube or sleeve to regulate fluid flow. When the valve is actuated, a mechanism compresses or "pinches" the sleeve, restricting or completely stopping the flow. These valves are particularly suited for handling slurries, abrasive materials, viscous fluids, or fluids with suspended solids, making them a popular choice in industries such as mining, wastewater treatment, chemical processing, and food and beverage. Their unique design ensures reliable performance and minimal maintenance in demanding environments.

One of the key advantages of pinch valves is their full-bore design, which eliminates any obstructions in the flow path when the valve is open. This design minimizes pressure drop and turbulence, making them highly efficient for systems requiring smooth fluid flow. The flexible sleeve is typically made from durable materials like natural rubber, silicone, or EPDM, chosen based on the fluid’s chemical compatibility and operating conditions. The absence of complex internal parts, such as seats or seals, reduces wear and tear, ensuring long-lasting performance even with abrasive or corrosive fluids.

Pinch valves are available in manual, pneumatic, or electric actuation options, providing flexibility to meet different operational needs. Manual valves are ideal for simple, low-cost setups, while pneumatic and electric options allow for remote control and automation in complex systems. Easy to install and maintain, pinch valves are a cost-effective solution for applications requiring robust and reliable flow control. By offering excellent durability, versatility, and ease of operation, pinch valves are a trusted choice for professionals managing challenging fluid handling systems.Interested in a Quote?

Advantages of Using Pinch Valves

-

Excellent for Handling Slurries and Solids

-

Minimal Fluid Contact with Valve Components

-

No Dead Zones or Cavities

-

Easy Maintenance and Replacement

-

Full Bore Flow

-

Reduced Noise and Vibration