- £0.01Unit price /Unavailable

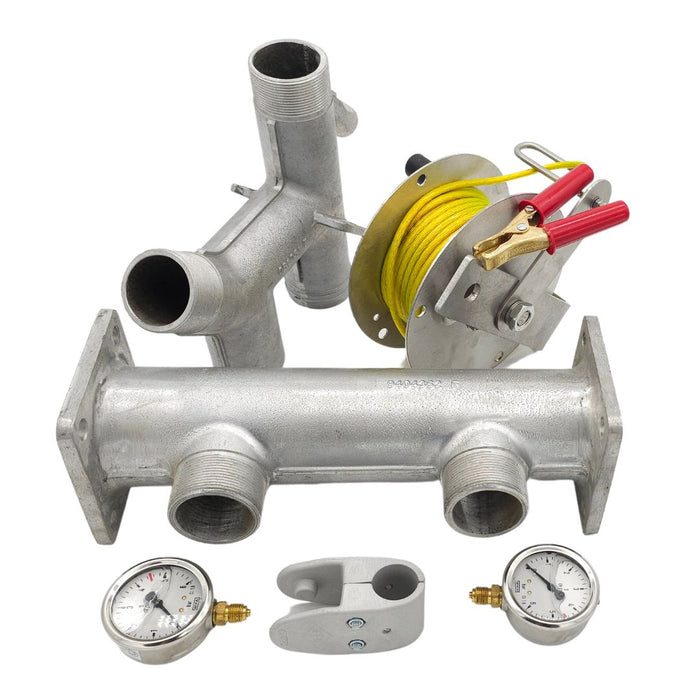

Combi Valve with BSP Females (Stainless Steel)

£0.01Unit price /Unavailable- £0.01Unit price /Unavailable

Air shut-off valves are critical components used to control and block the flow of air in pneumatic systems, ensuring safety, efficiency, and reliability. These valves are designed to provide rapid shut-off capability, which is essential during system maintenance, emergencies, or when air supply needs to be isolated to specific equipment. Air shut-off valves are widely used in industries such as manufacturing, construction, agriculture, and HVAC systems, where managing compressed air systems is crucial for operational efficiency and safety.

The design of air shut-off valves typically includes robust materials such as stainless steel, brass, or high-grade plastics, ensuring durability and resistance to corrosion and wear. They are available in various configurations, including manual, automatic, or solenoid-actuated versions. Manual air shut-off valves allow operators to control the airflow directly, making them ideal for systems that require occasional or planned shut-offs. Automatic shut-off valves, on the other hand, are triggered by specific conditions such as pressure loss, ensuring an added layer of safety without manual intervention. These valves are designed to handle high pressures and flow rates, ensuring compatibility with a wide range of pneumatic systems.

Air shut-off valves are valued for their precision and reliability, helping to protect equipment and ensure worker safety by preventing accidental air flow. They are easy to install and maintain, offering long-term performance with minimal downtime. Whether used in small-scale systems or large industrial setups, air shut-off valves are an indispensable part of pneumatic operations. By providing fast and effective airflow control, these valves enhance system efficiency and safety, making them a trusted choice for professionals across various industries.Interested in a Quote?

Advantages of Using Air Shut Off Valves

-

Enhanced Safety

-

Energy Efficiency

-

Equipment Protection

-

Facilitates Maintenance and Repairs

-

Leak Prevention

-

Compliance with Safety Standards