- Regular price £0.01Unit price /Unavailable

Road Tanker Hose Strap (Plastic)

Regular price £0.00Unit price /UnavailableLocking Valve with Lock Limit Switch

Regular price £0.00Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

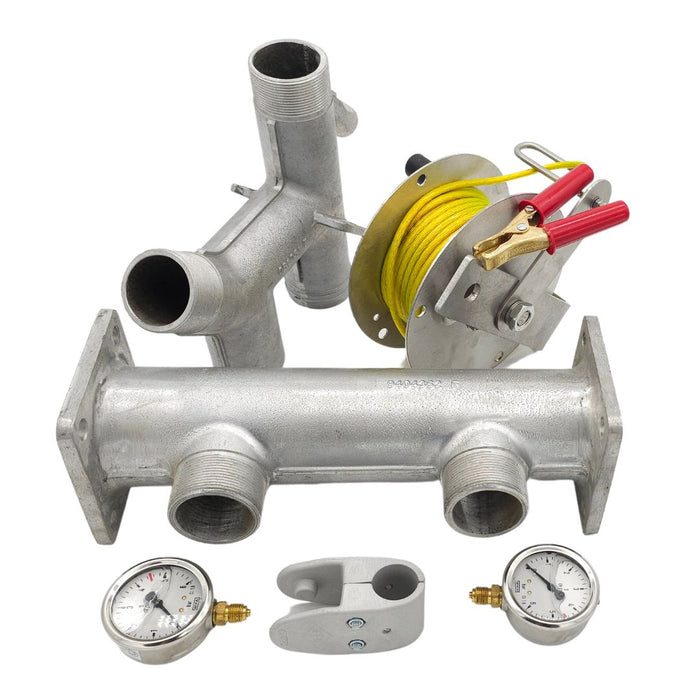

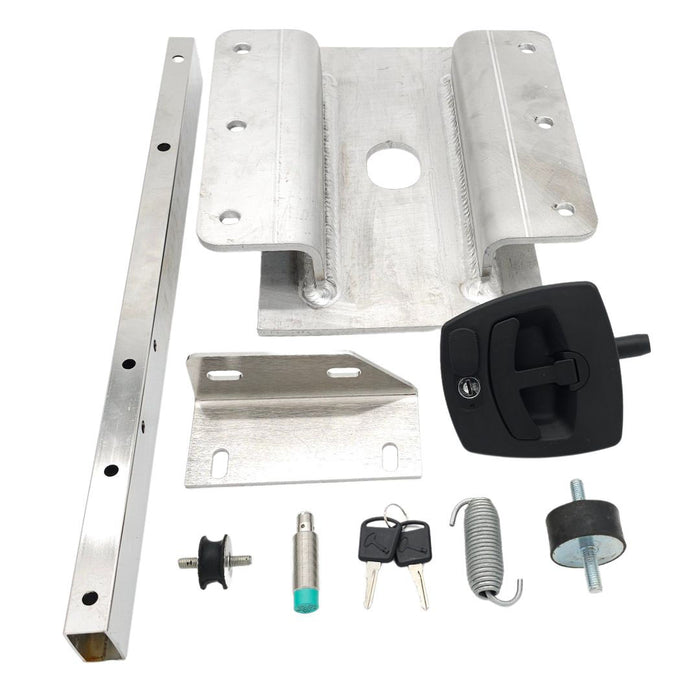

Hose carrier parts are vital accessories designed to enhance the functionality, security, and stability of hose storage and transport systems. Components such as locking bars, road tanker hose straps, and U-bolts play a critical role in ensuring hoses remain securely contained and protected during transport or storage. These parts are essential in industries such as firefighting, agriculture, road transport, and industrial fluid management, where the efficiency and reliability of hose handling systems are paramount. Each part serves a unique purpose, collectively contributing to the safe and organized management of hoses.

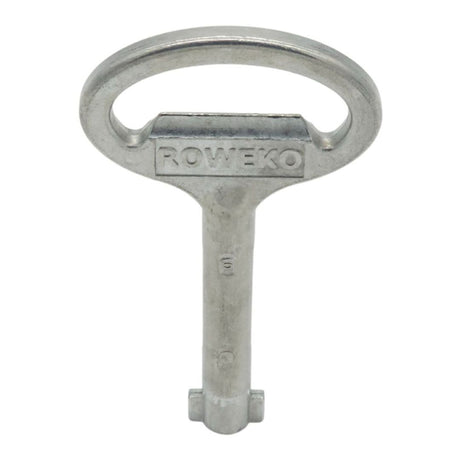

The locking bar is a key component that secures hose carrier doors or blanks, ensuring they remain firmly closed during transit. This prevents accidental openings and protects hoses from environmental damage, theft, or misplacement. Road tanker hose straps are designed to hold hoses firmly in place on tankers or trailers, minimizing movement during transport. These straps are typically made from durable materials like nylon or reinforced fabric, providing high tensile strength and resistance to wear. They are adjustable, allowing for flexibility in securing hoses of various sizes and configurations.

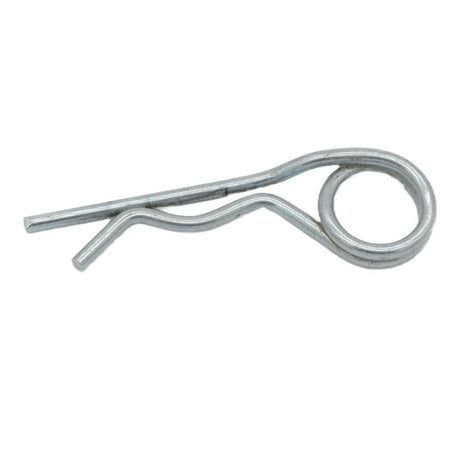

U-bolts are indispensable for mounting hose carrier tubes onto vehicles, trailers, or storage systems. Made from corrosion-resistant materials like stainless steel or galvanized steel, U-bolts provide a strong and reliable anchor point, ensuring the carrier tube stays securely in place even under heavy mechanical stress or vibration. In addition to these parts, a range of other accessories, such as end caps, hinges, and mounting brackets, further enhance the versatility and durability of hose carrier systems. By offering a comprehensive selection of hose carrier parts, professionals can customize and optimize their systems to meet specific operational needs, ensuring long-lasting performance and maximum efficiency.Interested in a Quote?

Advantages of Using Hose Carrier Accessories

-

Customization and Flexibility

-

Enhanced Protection

-

Improved Safety

-

Extended Equipment Lifespan

-

Optimized Performance

-

Adaptability to Harsh Environments: