SMS Female Coupling to Weld Liner (Stainless Steel)

Regular price £0.00Unit price /UnavailableSMS Coupling Nut (Stainless Steel)

Regular price £0.00Unit price /UnavailableSMS Male Coupling to Weld Liner (Stainless Steel)

Regular price £0.00Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

SMS Female Coupling Blank Cap (Stainless Steel)

Regular price £0.00Unit price /Unavailable

Not sure which SMS part you need?

Speak to an Expert Today!

Interested in a Quote?

SMS couplings and fittings are precision-engineered components designed to create secure, hygienic connections in fluid handling systems. Widely used in industries such as food and beverage, dairy, and pharmaceuticals, these couplings are specifically crafted to meet stringent hygiene standards. Featuring a threaded design with a union nut, SMS couplings ensure a tight, leak-free connection while allowing for easy assembly and disassembly, making them ideal for systems requiring frequent cleaning or maintenance. Their robust construction and compatibility with various piping and equipment make them a trusted solution for fluid transfer applications.

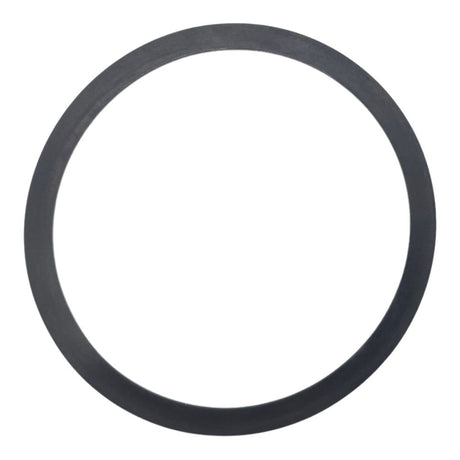

Manufactured from high-quality stainless steel, SMS couplings and fittings offer exceptional durability, corrosion resistance, and a polished, hygienic finish. Stainless steel is the material of choice for industries that prioritize cleanliness, as it resists contamination, withstands frequent sterilization, and performs reliably under demanding conditions. Available in a range of sizes, SMS couplings and fittings are adaptable to different pipe diameters and system configurations, ensuring compatibility with both small-scale and industrial-scale setups. Their versatile design makes them suitable for transporting liquids, gases, or powders in hygienic environments.

The precision engineering of SMS couplings and fittings ensures reliable performance and ease of use, reducing downtime and enhancing system efficiency. The threaded union nut allows for quick assembly and disassembly, facilitating routine maintenance or system modifications. Whether used in process lines, fluid transport systems, or sanitary applications, SMS couplings deliver consistent and dependable results. By offering a variety of sizes and durable stainless steel construction, SMS couplings and fittings provide a long-lasting, versatile solution for professionals seeking to optimize the performance, safety, and hygiene of their fluid handling systems.