Why Hose Inspection & Maintenance Matters

Hoses are subject to wear, pressure, movement and environmental exposure throughout their service life. Regular inspection and maintenance helps identify early signs of deterioration before failures occur.

Planned inspection programmes reduce unplanned downtime, improve safety and ensure hoses remain suitable for their intended application. Where issues are identified, hoses can be repaired, re-terminated or replaced as required to maintain safe operation.

What Inspection & Maintenance Checks Cover

Visual Condition

Checks for external damage, abrasion, corrosion and visible signs of fatigue.

Fittings & Connections

Inspection of couplings, crimps and end fittings for movement, wear or deterioration.

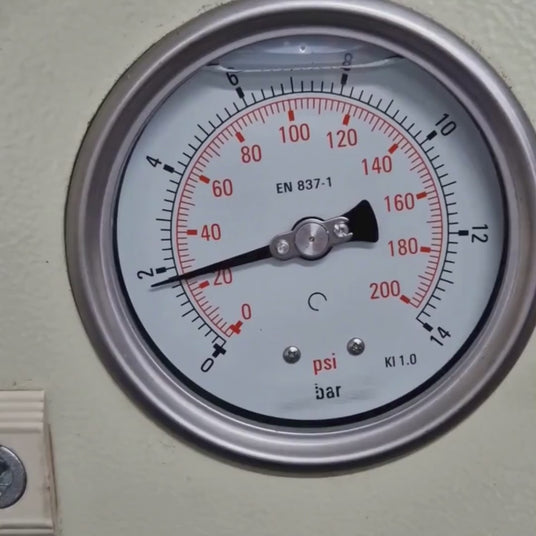

Application Suitability

Confirms the hose remains suitable for its operating pressure, temperature and media.

Serviceability Decision

Determines whether the hose can remain in service, requires maintenance or should be replaced.

Routine Inspection & Planned Maintenance

Routine inspection programmes help identify wear, damage and deterioration before they lead to hose failure.

JML Henderson supports planned inspection schedules tailored to your operation, helping maintain safety while reducing unplanned downtime. Inspection frequency can be aligned to hose application, risk level and operating environment.

Planned maintenance programmes may include:

- Scheduled inspection intervals based on application risk

- Fleet, tanker or site-based inspection programmes

- Identification of hoses approaching end-of-life

- Reduced emergency callouts and operational disruption

This proactive approach improves reliability and operational control.

Refurbishment & Re-termination

Where suitable, hose assemblies can be refurbished or re-terminated rather than fully replaced.

Inspection may identify hoses where the hose body remains serviceable but end fittings show signs of wear, damage or corrosion. In these cases, re-termination can restore the assembly to a safe, usable condition.

Refurbishment services may include:

- Replacement of worn or damaged end fittings

- Hose re-termination where the hose remains serviceable

- Verification prior to returning the hose to service

Refurbishment offers a cost-effective alternative to full hose replacement while maintaining safety and performance when carried out correctly and documented.

Inspection Linked to Testing & Certification

Inspection findings can be used to trigger pressure testing or re-certification where required. Linking inspection, testing and hose ID tagging provides full visibility of hose condition, compliance status and service history.

This integrated approach supports safer operation, audit readiness and informed maintenance decisions across the entire hose lifecycle.