Not sure which RJT part you need?

Speak to an Expert Today!

RJT Female Coupling to Serrated Hose Tail Liner (Stainless Steel)

Regular price £0.00Unit price /UnavailableRJT Female Coupling to Serrated Hose Tail (Stainless Steel)

Regular price £0.00Unit price /UnavailableRJT Male Coupling to Serrated Hose Tail (Stainless Steel)

Regular price £0.00Unit price /UnavailableRJT Swivel Female Coupling to BSP Male (Stainless Steel)

Regular price £0.00Unit price /UnavailableRJT Male Coupling to BSP Female Swivel (Stainless Steel)

Regular price £0.00Unit price /UnavailableRJT Male Coupling to Weld Liner (Stainless Steel)

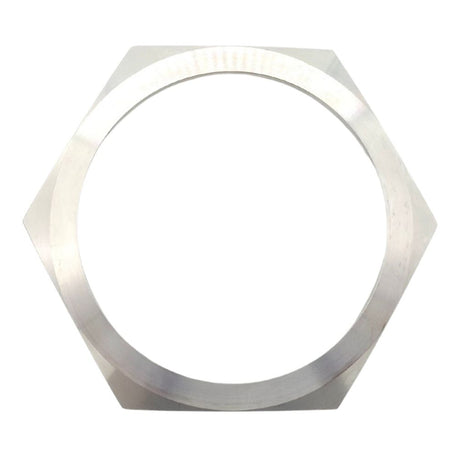

Regular price £0.00Unit price /UnavailableRJT Coupling Nut (Stainless Steel)

Regular price £0.00Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

- Regular price £0.00Unit price /Unavailable

RJT Female to Female Hygienic Butterfly Valve (Stainless Steel)

Regular price £0.00Unit price /UnavailableRJT Male to Female Swivel Adapter (Stainless Steel)

Regular price £0.00Unit price /UnavailableRJT Male Reducing Hose Tail (Stainless Steel)

Regular price £0.00Unit price /UnavailableRJT Male to RJT Female Swivel Reducer (Stainless Steel)

Regular price £0.00Unit price /UnavailableRJT Female Swivel to RJT Male 90° Bend (Stainless Steel)

Regular price £0.00Unit price /UnavailableRJT Female Plastic Blank Cap with Stainless Chain

Regular price £0.00Unit price /UnavailableRJT Cone Filter (Stainless Steel)

Regular price £0.00Unit price /UnavailableRJT Male Plug with Chain (Plastic)

Regular price £0.00Unit price /Unavailable

Not sure which RJT part you need?

Speak to an Expert Today!

Interested in a Quote?

Advantages of using RJT

-

Hygienic Design

RJT couplings are designed with smooth surfaces and minimal crevices, making them easy to clean and ideal for sanitary applications. This design helps maintain high hygiene standards, preventing contamination in food and beverage processing.

-

Ease of Assembly and Disassembly

RJT couplings can be quickly and easily assembled and disassembled, facilitating efficient cleaning and maintenance. This feature is particularly important in industries where frequent cleaning is required to ensure product quality.

-

Secure and Leak-Proof

The design of RJT couplings includes a metal-to-metal seal with an elastomeric O-ring, providing a secure and leak-proof connection. This ensures the integrity of the fluid transfer and prevents leaks.

-

Durability

Made from robust materials such as stainless steel, RJT couplings are highly durable and resistant to corrosion. Their durability ensures a long service life, even in demanding industrial environments.

-

Versatility

RJT couplings are available in a range of sizes and materials, making them suitable for various applications beyond food and beverage, including chemical and pharmaceutical industries. Their versatility allows them to be used in different processing systems.

-

Standardization

RJT couplings conform to industry standards, ensuring compatibility and interchangeability with other RJT components. This standardization simplifies the integration of RJT couplings into existing systems and ensures that replacement parts are easily obtainable.

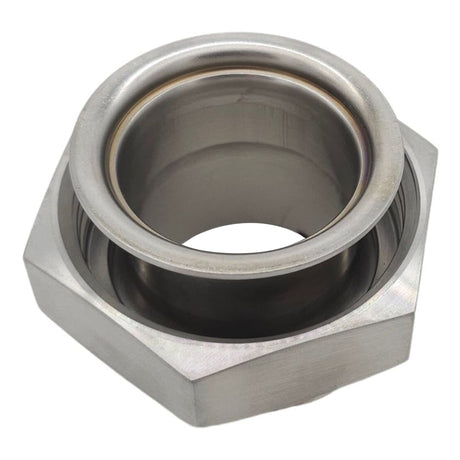

RJT couplings and fittings are essential components designed for creating secure and hygienic connections in fluid transfer systems. Available in both male and female configurations, these fittings are widely used in industries such as food and beverage, dairy, and pharmaceuticals, where maintaining cleanliness and reliability is crucial. RJT couplings feature a threaded design with a union nut, ensuring a tight, leak-free connection while allowing for easy disassembly during cleaning or maintenance. Their robust construction and hygienic properties make them indispensable for applications handling sensitive or consumable fluids.

Constructed from high-quality stainless steel, RJT couplings and fittings offer exceptional durability, corrosion resistance, and a smooth, hygienic finish. Stainless steel is an ideal material for environments requiring frequent cleaning and sterilization, as it resists contamination and maintains integrity even under harsh conditions. Available in a range of sizes, RJT couplings are versatile and compatible with various pipe and hose dimensions, making them suitable for small-scale setups and large industrial systems alike. Their polished surface ensures easy cleaning, meeting the strict hygiene standards of industries dealing with consumable products.

The precision engineering of RJT couplings ensures easy installation and reliable performance, reducing downtime and enhancing system efficiency. The threaded design allows for quick assembly and disassembly, making these fittings ideal for systems that require regular maintenance or reconfiguration. Whether used to connect pipes, integrate hoses, or attach equipment, RJT couplings deliver consistent performance and long-lasting durability. With their availability in a variety of sizes and configurations, stainless steel RJT couplings and fittings are a trusted choice for professionals seeking to optimize the reliability and hygiene of their fluid transfer systems.