Not sure which BSP part you need?

Speak to an Expert Today!

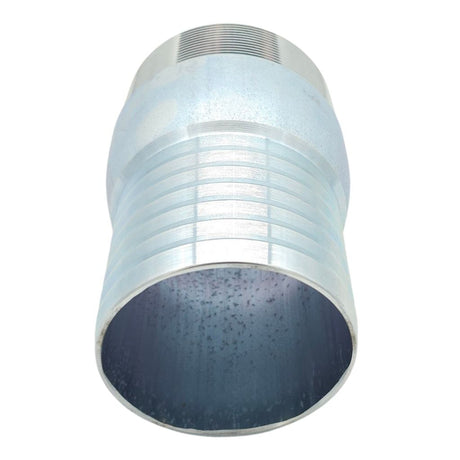

BSP Male to Serrated Hose Tail (Mild Steel)

Regular price £0.00Unit price /UnavailableBSP Male to Serrated Hose Tail (Stainless Steel)

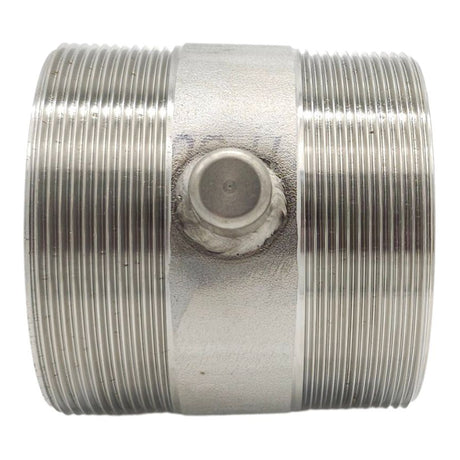

Regular price £0.00Unit price /UnavailableBSP Male to BSP Male Hex Nipple (Stainless Steel)

Regular price £0.00Unit price /UnavailableBSP Male to BSP Male Hex Nipple (Brass)

Regular price £0.00Unit price /UnavailableBSP Male Barrel Nipple (Stainless Steel)

Regular price £0.00Unit price /UnavailableBSP Half Socket (Stainless Steel)

Regular price £0.00Unit price /UnavailableBSP Female Socket (Stainless Steel)

Regular price £0.00Unit price /UnavailableBSP Male to BSP Male 45° Bend (Aluminium)

Regular price £0.00Unit price /UnavailableBSP Male Weld Stub (Mild Steel)

Regular price £0.00Unit price /UnavailableBSP Male Weld Stub (Stainless Steel)

Regular price £0.00Unit price /UnavailableBSP Male Running Nipple (Stainless Steel)

Regular price £0.00Unit price /UnavailableBSP Female Equal Tee Piece (Stainless Steel)

Regular price £0.00Unit price /UnavailableBSP Male to BSP Female Adapter (Stainless Steel)

Regular price £0.00Unit price /UnavailableBSP Female Smooth Hose Tail to Suit Safety Clamp (Stainless Steel)

Regular price £0.00Unit price /UnavailableBSP Male Ribbed Hose Tail Long (Aluminium)

Regular price £0.00Unit price /UnavailableBSP Male Ribbed Hose Tail (Aluminium)

Regular price £0.00Unit price /UnavailableBSP Female Blank Cap - Lugged & Chain (Aluminium)

Regular price £0.00Unit price /UnavailableBSP Male Blank Plug - Lugged & Chain (Aluminium)

Regular price £0.00Unit price /UnavailableBSP Blank Plug (Stainless Steel)

Regular price £0.00Unit price /UnavailableBSP Female Blank Cap - Lugged & Chain (Stainless Steel)

Regular price £0.00Unit price /UnavailableBSP Female Serrated Hose Tail (Aluminium)

Regular price £0.00Unit price /UnavailableBSP Male Blue Plastic Blank Plug

Regular price £0.00Unit price /UnavailableBSP Male to BSP Female Reducing/Enlarger Adapter (Stainless Steel)

Regular price £0.00Unit price /UnavailableBSP Male to BSP Male Lugged Adapter (Stainless Steel)

Regular price £0.00Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

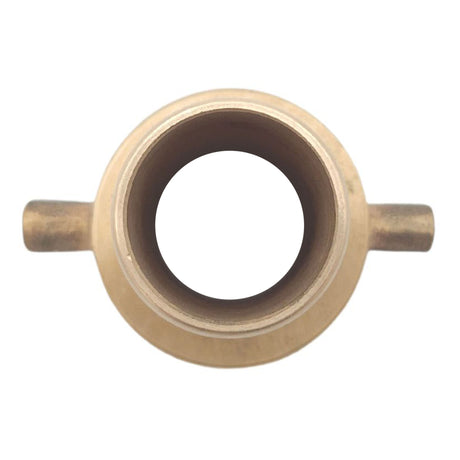

BSP Female Serrated Hose Tail (Gunmetal)

Regular price £0.00Unit price /UnavailableBSP Female to BSP Female Union (Stainless Steel)

Regular price £0.00Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

1.5" BSP Female x 90° Bend x 1.5" Serrated Tail

Regular price £0.00Unit price /Unavailable3" + 2.5" BSP Lug Spanner (Steel)

Regular price £0.00Unit price /UnavailableBSP Male Smooth Hose Tail to Suit Safety Clamp (Brass)

Regular price £0.01Unit price /UnavailableBSP Male Serrated Hose Tail (Brass)

Regular price £0.01Unit price /UnavailableBSP Male to BSP Male Adaptor (Aluminium)

Regular price £0.01Unit price /UnavailableBSP Male to BSP Female Adaptor (Aluminium)

Regular price £0.01Unit price /UnavailableBSP Male to BSP Female Reducing/Enlarger (Aluminium)

Regular price £0.01Unit price /UnavailableBSP Male Smooth Hose Tail to Suit Safety Clamp (Stainless Steel)

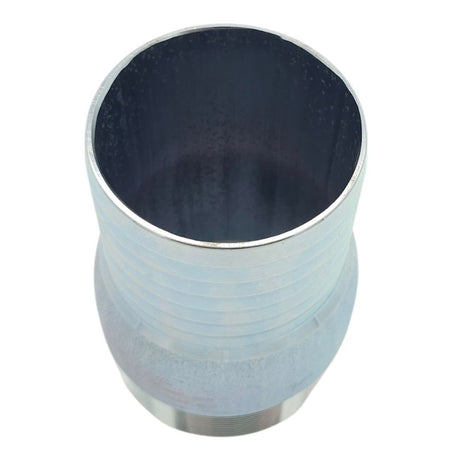

Regular price £0.01Unit price /UnavailableBSP Female to BSP Female Reducer (Aluminium)

Regular price £0.01Unit price /Unavailable

Not sure which BSP part you need?

Speak to an Expert Today!

Interested in a Quote?

Advantages of using BSP

-

Standardisation

BSP couplings adhere to a standardized system, ensuring compatibility and interchangeability among components from different manufacturers. This standardization simplifies the design, maintenance, and repair of piping systems.

-

Versatility

BSP couplings are available in a wide range of sizes and materials, making them suitable for various applications, including water supply, gas, and hydraulic systems. Their versatility allows them to be used in residential, commercial, and industrial settings.

-

Ease of Installation:

BSP couplings feature a simple and straightforward installation process, often requiring only basic tools. The threaded design ensures a secure and tight connection, reducing the likelihood of leaks.

-

Leak Resistance

The tapered thread design of BSPT (British Standard Pipe Tapered) couplings provides a tight seal that becomes more secure under pressure. This design reduces the risk of leaks and ensures reliable performance in high-pressure applications.

-

Durability

BSP couplings are typically made from durable materials such as brass, stainless steel, or galvanized steel, offering excellent resistance to corrosion and wear. This durability ensures a long service life and reduces the need for frequent replacements.

-

Wide Availability

BSP couplings are widely available globally, which means they can be easily sourced from numerous suppliers. This broad availability ensures that replacements or additional components can be quickly and conveniently obtained, minimizing downtime in maintenance or expansion projects.

BSP couplings and fittings are versatile components designed for securely connecting pipes, hoses, and equipment with British Standard Pipe (BSP) threads. Available in both male and female configurations, these fittings are widely used across industries such as agriculture, construction, chemical processing, and fluid management. Their precision engineering ensures reliable, leak-free connections, making them an essential choice for systems handling liquids, gases, or slurries. BSP couplings and fittings provide a robust and efficient solution for creating durable connections in both temporary and permanent setups.

Crafted from a variety of materials, including stainless steel, alloy, mild steel, and brass, BSP couplings and fittings offer options to suit different operational requirements. Stainless steel fittings provide superior corrosion resistance and durability, ideal for harsh environments or applications involving aggressive fluids. Alloy fittings combine strength and wear resistance, making them suitable for high-pressure or high-temperature systems. Mild steel options offer a cost-effective solution with solid mechanical properties for general-purpose use, while brass fittings are highly resistant to corrosion and provide excellent conductivity, making them suitable for plumbing and low-pressure applications. These materials ensure compatibility with diverse industries and operating conditions.

Available in a range of sizes, BSP couplings and fittings are adaptable to various pipe diameters and system configurations, making them suitable for both small-scale and industrial-scale applications. Their threaded design ensures ease of installation, maintenance, and replacement, minimizing downtime during system adjustments or repairs. Whether used to join pipes, extend connections, or integrate equipment, BSP couplings and fittings deliver reliable performance and long-term durability. By offering multiple material options, sizes, and configurations, these fittings provide a practical and dependable solution for optimizing the efficiency and reliability of fluid transfer systems.