Hose Carrier Stainless Steel Chassis Bracket

Regular price £0.00Unit price /UnavailableHose Carrier Stainless Steel Upright Short (300mm)

Regular price £0.00Unit price /UnavailableHose Carrier Stainless Steel Upright Long (590mm)

Regular price £0.00Unit price /UnavailableSingle Stainless Steel Hose Carrier Bracket (160mm)

Regular price £0.01Unit price /UnavailableSingle Stainless Steel Hose Carrier Bracket (200mm)

Regular price £0.01Unit price /UnavailableDouble Stainless Steel Hose Carrier Bracket (200mm)

Regular price £0.01Unit price /UnavailableDouble Stainless Steel Hose Carrier Bracket (160mm)

Regular price £0.01Unit price /Unavailable

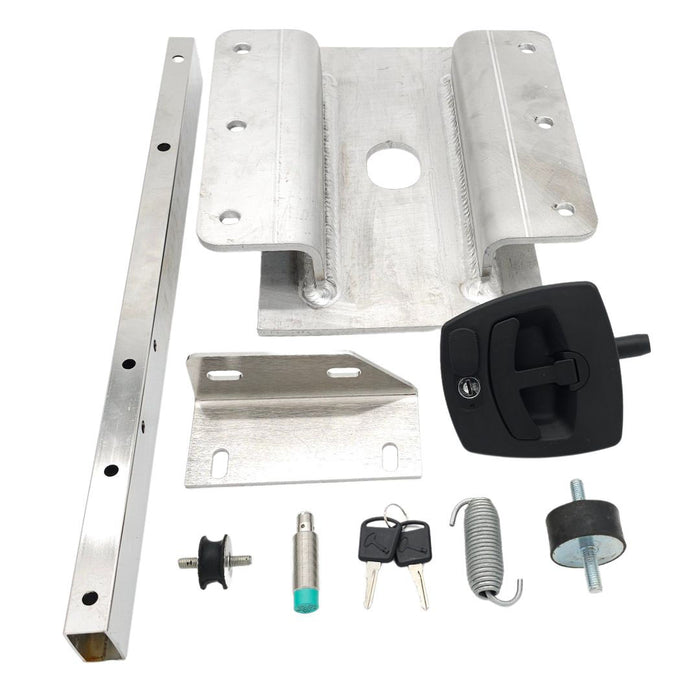

Hose carrier brackets are essential mounting accessories designed to securely attach hose carrier tubes to vehicles, trailers, or storage systems. These brackets ensure that hose carrier tubes remain firmly in place during transport or operation, protecting hoses from damage and ensuring easy access when needed. Available in sizes to fit 160mm and 200mm internal diameter (ID) tubes, hose carrier brackets are commonly used in industries such as firefighting, agriculture, and industrial fluid handling. They provide a reliable solution for professionals who need to organize and secure their hoses effectively.

Constructed from durable stainless steel, hose carrier brackets offer exceptional strength and corrosion resistance, making them ideal for demanding environments, including outdoor and marine applications. The stainless steel material ensures long-lasting performance, even under harsh conditions, such as exposure to moisture, chemicals, or heavy mechanical stress. Hose carrier brackets are available in single and double configurations, offering flexibility for different mounting requirements. Single brackets provide a straightforward solution for lighter or shorter carrier tubes, while double brackets offer enhanced stability and support for larger or heavier systems.

Designed for easy installation, hose carrier brackets feature precision engineering to ensure a secure and reliable fit with carrier tubes. Their robust construction minimizes vibrations and movement during transport, reducing the risk of wear or damage to the hoses or carrier. By offering a variety of sizes and configurations, stainless steel hose carrier brackets are a practical and dependable solution for professionals looking to enhance the functionality, safety, and durability of their hose storage and transport systems.Interested in a Quote?

Advantages of Using Hose Carrier Brackets

-

Secure Mounting

-

Support and Stability

-

Flexible Installation Options

-

Ease of Maintenance and Adjustment

-

Vibration Dampening

-

Enhanced Safety