- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

- Regular price £0.00Unit price /Unavailable

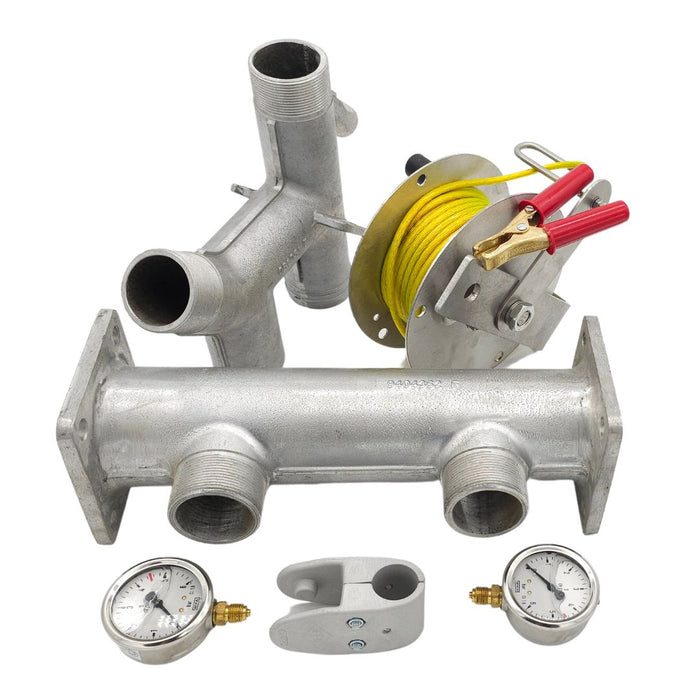

Aeration pads are specialized components designed to facilitate the flow of dry bulk materials, such as powders, grains, and granules, in storage and transport systems. These pads are installed in silos, hoppers, and bins to prevent material blockages and ensure smooth discharge by introducing controlled air into the material. By breaking up compaction and reducing friction between particles and container walls, aeration pads are essential for maintaining efficient material handling in industries such as agriculture, food processing, cement production, and chemical manufacturing.

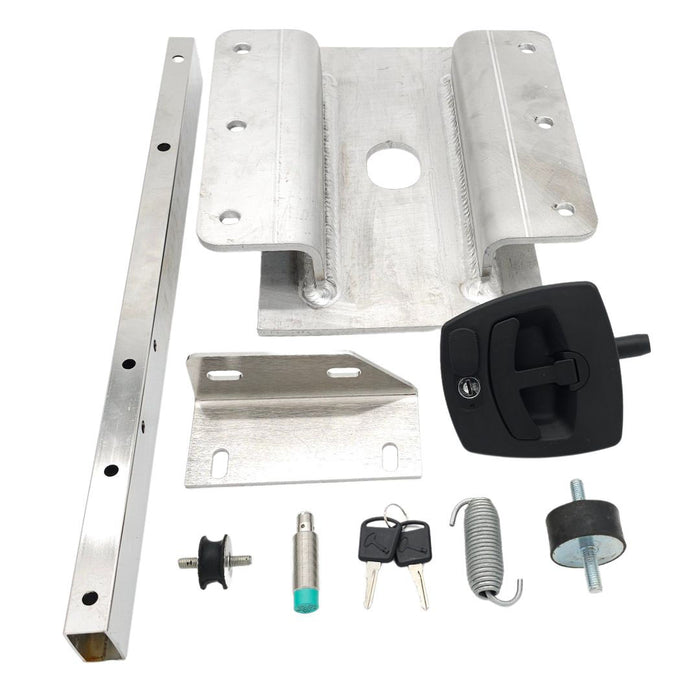

The design of aeration pads typically includes a durable base plate fitted with a porous membrane or fabric that allows air to flow through while preventing material backflow. This setup ensures uniform air distribution, gently fluidizing the material to improve flow without causing excessive turbulence or degradation. Aeration pads are often made from robust materials like stainless steel, aluminum, or reinforced plastic, ensuring durability and resistance to abrasion and chemical exposure. They are available in various shapes and sizes to suit different applications and system configurations.

Aeration pads are easy to install and require minimal maintenance, making them a cost-effective solution for improving material handling efficiency. Regular cleaning and inspection ensure consistent performance and prevent clogging of the porous membrane. By reducing blockages and material waste, aeration pads help minimize downtime and enhance the productivity of bulk material systems. Their ability to handle a wide range of materials and operating conditions makes aeration pads a versatile and reliable choice for industries seeking to optimize their material flow processes.