- £0.00Unit price /Unavailable

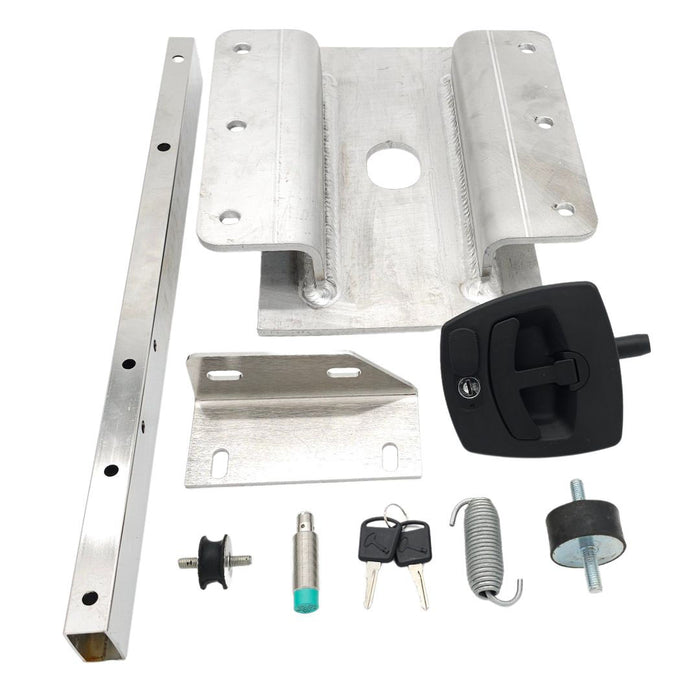

Universal Joint Coupling for Butterfly Valve

£0.01Unit price /UnavailableUniversal Joint Heavy Duty Coupling (Square)

£0.01Unit price /UnavailableUniversal Joint Coupling - (Square)

£0.01Unit price /UnavailableRemote Control Single Wear Bracket (Plastic)

£0.00Unit price /Unavailable

Universal joints, also known as U-joints, are mechanical components designed to transmit rotational power between two shafts that are not in a straight line. These joints allow for angular misalignment, making them essential in systems where flexibility is required. Universal joints are widely used in industries such as automotive, agriculture, industrial machinery, and marine applications. Their ability to accommodate varying shaft angles ensures smooth power transmission and efficient operation, even in dynamic or shifting environments.

The design of a universal joint typically consists of a cross-shaped hub (yoke) with bearings at each end, connecting two shafts at a pivoting point. This configuration allows the shafts to rotate at different angles while maintaining a constant transmission of torque. Universal joints are available in single or double configurations. Single U-joints are suitable for moderate angular misalignment, while double U-joints provide greater flexibility and are used in applications requiring complex movement or alignment correction. Materials such as steel or stainless steel are commonly used for durability and strength, ensuring the joints perform reliably under high stress and load conditions.

Universal joints are valued for their versatility and durability, making them a cost-effective solution for a wide range of applications. They are easy to install and maintain, with replaceable components that extend their lifespan. Proper lubrication and regular inspection are essential to ensure smooth operation and minimize wear. Whether used in vehicle drive shafts, industrial conveyors, or marine propulsion systems, universal joints provide a reliable and efficient means of transmitting rotational power across misaligned axes, making them an indispensable component in many mechanical systems.Interested in a Quote?

Advantages of Using Universal Joints

-

Flexibility in Motion

-

Efficient Power Transmission

-

Wide Range of Motion

-

Reduced Stress on Components

-

Smooth Operation at Variable Angles

-

Simple Design and Low Maintenance