Not sure which Wilcox part you need?

Speak to an Expert Today!

Wilcox Male Coupling to Serrated Hose Tail (Gunmetal)

Regular price £0.01Unit price /UnavailableWilcox Male Coupling to Serrated Hose Tail (Aluminium)

Regular price £0.01Unit price /UnavailableWilcox Female Coupling to Serrated Hose Tail (Stainless Steel)

Regular price £0.01Unit price /UnavailableWilcox Female Coupling to Serrated Hose Tail (Aluminium)

Regular price £0.01Unit price /UnavailableWilcox Female Coupling to Serrated Hose Tail (Gunmetal)

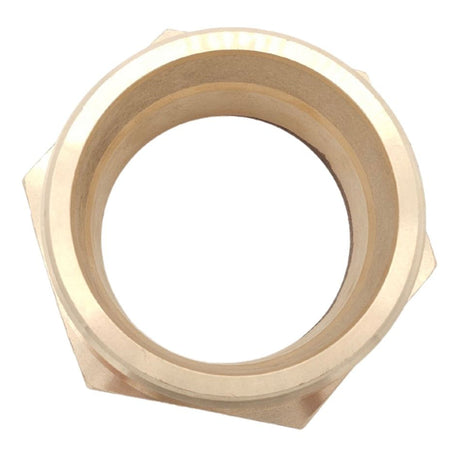

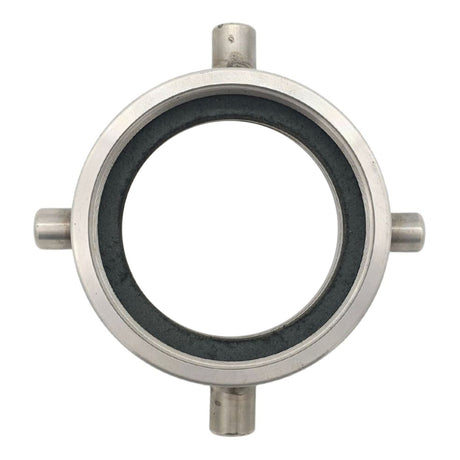

Regular price £0.01Unit price /Unavailable4" Wilcox Female Coupling Nut (Stainless Steel)

Regular price £0.01Unit price /Unavailable4" Wilcox Female Coupling Nut (Gunmetal)

Regular price £0.01Unit price /Unavailable4" Wilcox Female Coupling Nut (Aluminium)

Regular price £0.01Unit price /UnavailableWilcox Male Coupling to BSP Male Reducer (Stainless Steel)

Regular price £0.01Unit price /UnavailableWilcox Male Coupling to BSP Male (Gunmetal)

Regular price £0.01Unit price /UnavailableWilcox Female Coupling to BSP Male (Gunmetal)

Regular price £0.01Unit price /UnavailableWilcox Male Coupling to BSP Female (Gunmetal)

Regular price £0.01Unit price /UnavailableWilcox Female Fixed Coupling to BSP Female (Stainless Steel)

Regular price £0.01Unit price /UnavailableWilcox Female Coupling to BSP Female (Gunmetal)

Regular price £0.01Unit price /UnavailableWilcox Swivel Female Coupling to BSP Swivel Female (Gunmetal)

Regular price £0.01Unit price /UnavailableWilcox Female Swivel Coupling to BSP Male (Stainless Steel)

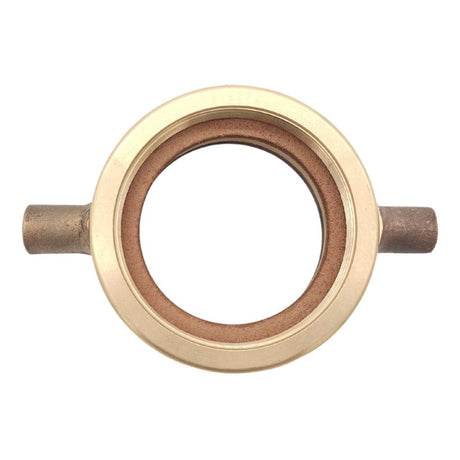

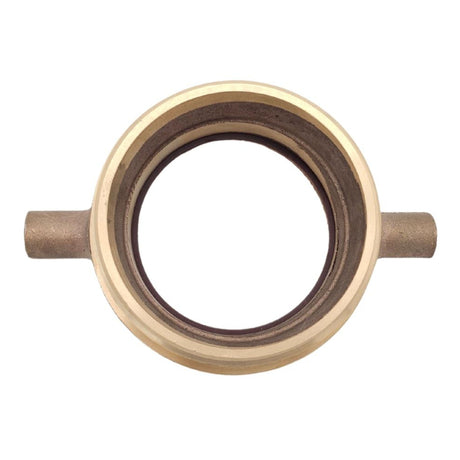

Regular price £0.01Unit price /UnavailableWilcox Male to Male Lugged Spool (Stainless Steel)

Regular price £0.01Unit price /Unavailable4" Wilcox Female Blank Cap (Stainless Steel)

Regular price £0.01Unit price /Unavailable4" Wilcox Male Blank Bung with Chain (Gunmetal)

Regular price £0.01Unit price /UnavailableWilcox Female Blank Cap (Aluminium)

Regular price £0.01Unit price /UnavailableWilcox Male Coupling to Weld Stub (Aluminium)

Regular price £0.01Unit price /UnavailableUnicone Coupling to Wilcox Female Adapter (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling to Wilcox Male Adapter (Stainless Steel)

Regular price £0.01Unit price /UnavailableWilcox Coupling Spanner (Steel)

Regular price £0.01Unit price /Unavailable4" Wilcox Coupling Spanner (Aluminium)

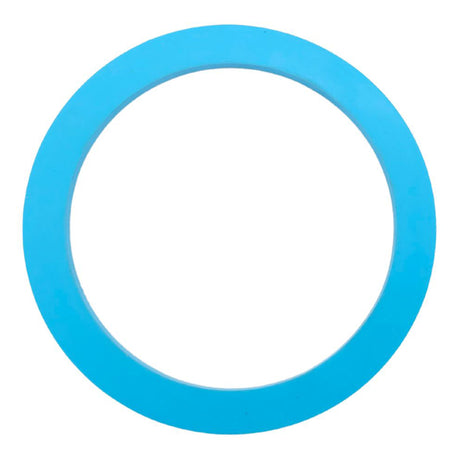

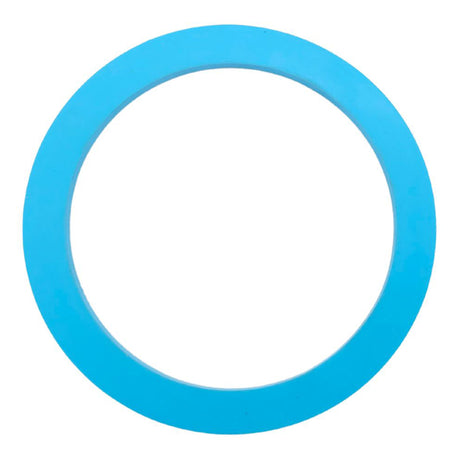

Regular price £0.01Unit price /Unavailable4" Wilcox Blue Food Quality Seal (Rubber)

Regular price £0.01Unit price /Unavailable- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

Wilcox White Food Grade Stepped Seal (Rubber)

Regular price £0.00Unit price /UnavailableWilcox Female Blank Cap (Plastic)

Regular price £0.00Unit price /Unavailable

Not sure which Wilcox part you need?

Speak to an Expert Today!

Interested in a Quote?

Advantages of using Wilcox

-

High-Pressure Capability

Wilcox couplings are designed to withstand high-pressure environments, making them ideal for applications in industries such as oil and gas, petrochemical, and hydraulics. Their ability to handle high pressure ensures safe and efficient operations.

-

Leak-Proof Seal

These couplings provide a secure and leak-proof connection, essential for preventing fluid or gas leaks. This feature is particularly important in handling hazardous or valuable substances, ensuring environmental protection and product integrity.

-

Durability and Longevity

Constructed from high-quality materials like stainless steel, Wilcox couplings are highly durable and resistant to corrosion and wear. This durability ensures a long service life, even in harsh operating conditions, reducing the need for frequent replacements.

-

Ease of Installation

Wilcox couplings are designed for easy installation and disconnection, often without the need for specialized tools. This ease of use enhances operational efficiency and reduces downtime during maintenance or system changes.

-

Versatility

Suitable for a wide range of applications, Wilcox couplings can handle various fluids and gases, including oil, water, chemicals, and compressed air. Their versatility makes them a valuable component across different industrie.

-

Safety Features

Many Wilcox couplings include safety mechanisms such as locking systems to prevent accidental disconnections. These features enhance the safety of operations, especially in high-pressure or hazardous environments.

Wilcox couplings and fittings are highly durable and versatile components designed for secure and efficient fluid transfer connections. These couplings are widely used in industries such as marine, firefighting, industrial fluid handling, and agriculture, where reliability and adaptability are critical. Featuring robust construction and precision engineering, Wilcox couplings and fittings provide leak-free performance, making them ideal for systems handling water, fuels, chemicals, and other fluids. Their compatibility with a variety of hoses and pipelines ensures versatility across diverse applications.

Manufactured from materials such as gunmetal, stainless steel, and aluminum, Wilcox couplings and fittings cater to a range of operational requirements. Gunmetal, a corrosion-resistant bronze alloy, is ideal for marine and saltwater applications due to its exceptional durability in harsh environments. Stainless steel fittings offer superior resistance to corrosion, chemicals, and high pressures, making them suitable for industrial and food-grade systems. Aluminum couplings, being lightweight yet strong, are perfect for portable systems or applications requiring easy handling and mobility. These material options provide solutions tailored to specific industry demands and environmental conditions.

Available in a range of sizes, Wilcox couplings and fittings are adaptable to different hose and pipe dimensions, ensuring compatibility with various system setups. Their user-friendly design allows for quick assembly and disassembly, minimizing downtime and enhancing operational efficiency. Whether used in permanent installations or temporary setups, these couplings and fittings deliver consistent, reliable performance. By offering a variety of materials and sizes, Wilcox couplings and fittings provide a dependable solution for professionals seeking to optimize the safety, efficiency, and durability of their fluid handling systems.