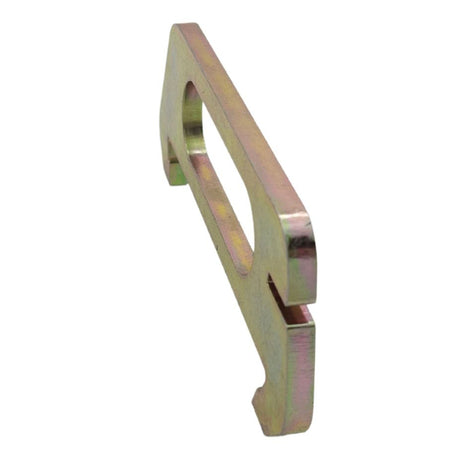

Unicone Coupling Clamp with Pin and Chain (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Clamp with Rubber Seal

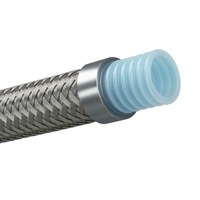

Regular price £0.01Unit price /UnavailableUnicone Coupling Serrated Tail (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Serrated Hose Tail (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling to BSP Male Long (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Plain Hose Tail (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Plain Hose Tail (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Serrated Tail with Filter Grid (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Reducing/Enlarging Hose Tail

Regular price £0.01Unit price /UnavailableUnicone Coupling to BSP Female Long (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling to BSP Female Short (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Weld End (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Weld End (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling to BSP Female Long (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling to BSP Female Short (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling to BSP Male Short (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling to BSP Male Short (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling to BSP Male Long (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Brown Neoprene Rubber Seal (High Temperature)

Regular price £0.01Unit price /UnavailableUnicone Coupling White Rubber Seal (Food)

Regular price £0.01Unit price /UnavailableUnicone Coupling Blue Rubber Seal (Food)

Regular price £0.01Unit price /UnavailableUnicone Coupling Black Rubber Seal (Abrasion Resistant)

Regular price £0.01Unit price /UnavailableUnicone Coupling Blank Cap (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Blank Cap (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Blank Cap (Blue Rubber)

Regular price £0.01Unit price /UnavailableUnicone Coupling Aluminium Insert Complete

Regular price £0.01Unit price /UnavailableUnicone Coupling Clamp with Twist Lock (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Clamp with Auto Lock (Mild Steel)

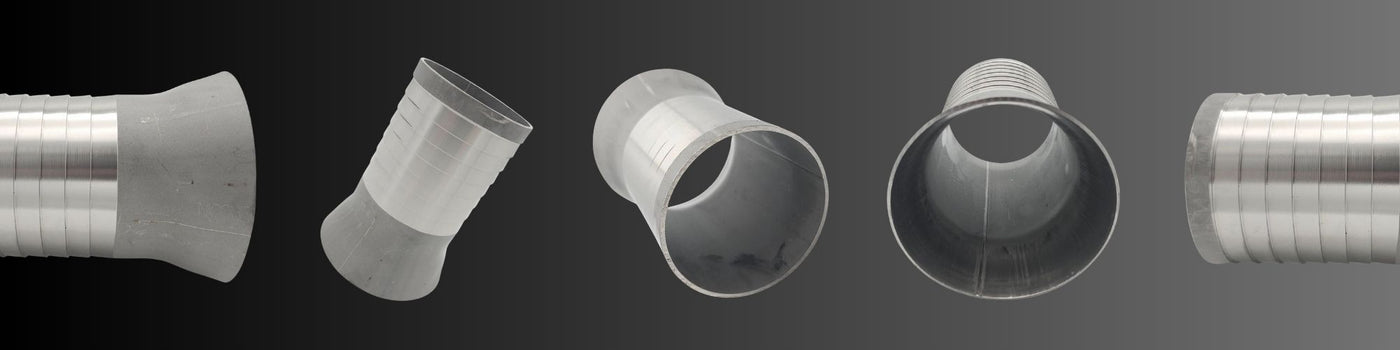

Regular price £0.01Unit price /UnavailableUnicone Coupling 45° Elbow (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling 90° Elbow (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling 45° Elbow (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling 90° Elbow (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Flanged Adapter (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Reducer (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Reducer (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling to Wilcox Female Adapter (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling to Wilcox Male Adapter (Stainless Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Serrated Hose Tail SCH40 (Mild Steel)

Regular price £0.01Unit price /UnavailableUnicone Coupling Serrated Hose Tail Self Colour SCH40

Regular price £0.01Unit price /Unavailable- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

Unicone Coupling Clamp Extension Handle

Regular price £0.01Unit price /UnavailableStorz Lockable Coupling to Unicone Adapter

Regular price From £0.01Unit price /UnavailableStorz Coupling to Unicone Adapter (Stainless Steel)

Regular price £0.01Unit price /UnavailableStorz Lockable Coupling to Unicone Adapter (Stainless Steel)

Regular price £0.00Unit price /UnavailableStorz Coupling to Unicone Adapter (Mild Steel)

Regular price £0.01Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

Unicone Coupling to URT Female (Stainless Steel)

Regular price £0.00Unit price /Unavailable

Interested in a Quote?

Advantages of using Unicone

-

Ease of Use

Unicone couplings often feature quick-connect and quick-disconnect mechanisms that facilitate speedy hose connections without the need for tools. Due to their simple design, these couplings are generally easy to use, requiring little to no specialized training.

-

Versatility

Unicone couplings are versatile and can be used in a variety of applications, including hydraulic, pneumatic, and fluid systems. Many unicone couplings are designed to be compatible with hoses of various materials and sizes, adding flexibility to the system.

-

Durability and Reliability

These couplings are designed to form a strong, leak-proof seal, essential for maintaining the integrity of fluid or gas systems. They are often made from durable materials like stainless steel or brass that offer corrosion resistance and long-lasting reliability.

-

Safety Features

The secure connection reduces the likelihood of leaks, thereby improving safety and minimizing waste. Some designs come with additional locking features to prevent accidental disconnections, enhancing safety.

-

Cost-Effectiveness

The durable construction and reliable sealing usually mean that these couplings require minimal maintenance, thereby reducing operational costs. Many unicone couplings can be disconnected and reused, offering long-term cost savings.

-

Operational Efficiency

The quick-connect and disconnect features mean that hoses can be changed or maintained with minimal disruption to operations. These couplings are often designed to minimize flow restrictions, thereby maintaining system efficiency