Mikalor Super Heavy-Duty T Bolt Hose Clamp (W1)

Regular price £0.01Unit price /UnavailableMikalor Supra Heavy-Duty T Bolt Hose Clamp (W2)

Regular price £0.01Unit price /UnavailableMikalor Supra Heavy-Duty T Bolt Hose Clamp (W4)

Regular price £0.01Unit price /UnavailableMikalor Supra Heavy-Duty T Bolt Hose Clamp (W5)

Regular price £0.01Unit price /UnavailableMikalor Supra Constant Tension Heavy-Duty Clamp (W2)

Regular price £0.01Unit price /UnavailableMikalor Supra Constant Tension Heavy-Duty Clamp (W4)

Regular price £0.01Unit price /UnavailableMikalor Normal T Bolt Mini-Clamp (W1)

Regular price £0.01Unit price /UnavailableMikalor Fixed Diameter "S" T Bolt Clamp (W1)

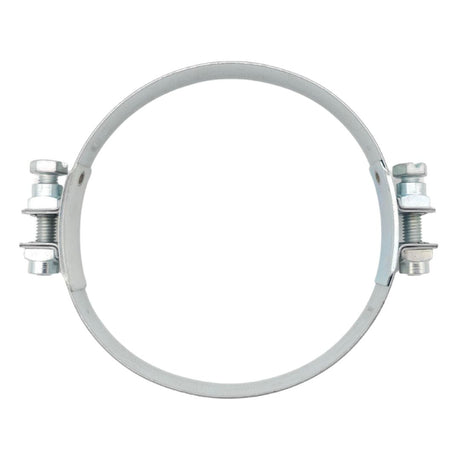

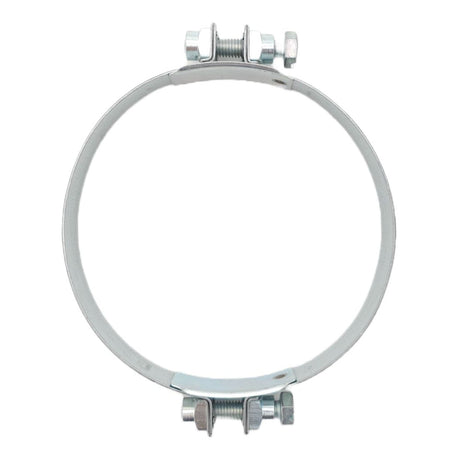

Regular price £0.01Unit price /UnavailableNorma Double Bolt Hose Clip (W1)

Regular price £0.00Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

Need help finding the right part?

Speak to an Expert Today!