- New arrival

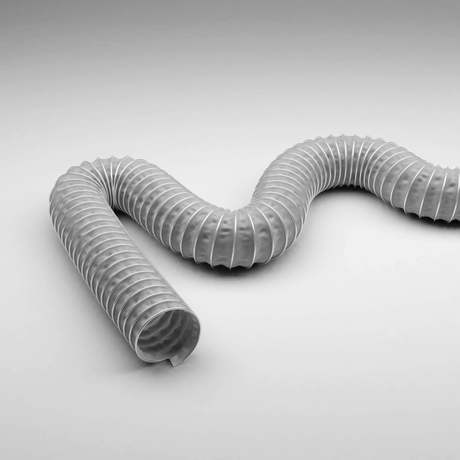

VULCANO® TPR-A High Temperature TPV Ventilation Hose

Regular price £0.00Unit price /Unavailable - New arrival

IPL Silduct 2S High Temperature Silicone Coated Glass Fabric Hose

Regular price £0.00Unit price /Unavailable Master Clip HT 450 Heat Protective S&D Ducting Hose

Regular price £0.00Unit price /UnavailableMaster Clip HT 400 Heat Protective S&D Ducting Hose

Regular price £0.00Unit price /UnavailableMaster Clip Vinyl B High Temperature S&D Ducting Hose

Regular price £0.00Unit price /UnavailableContinental Thermo Resistant PU 200°C S&D Hot Air Hose

Regular price £0.00Unit price /Unavailable

Not sure which hose is right for your application?

Speak to an Expert Today!

Interested in a Quote?

About Our High Temperature Ducting