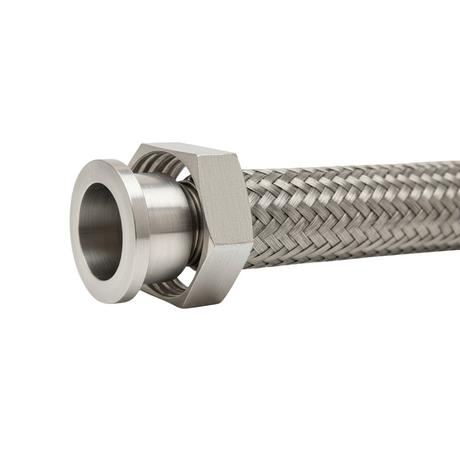

ProFlow PTFE Hose with Stainless Steel Tri-Clamp Fittings

Regular price £0.00Unit price /UnavailableProFlow PTFE Hose with Stainless Steel SMS Female Fittings

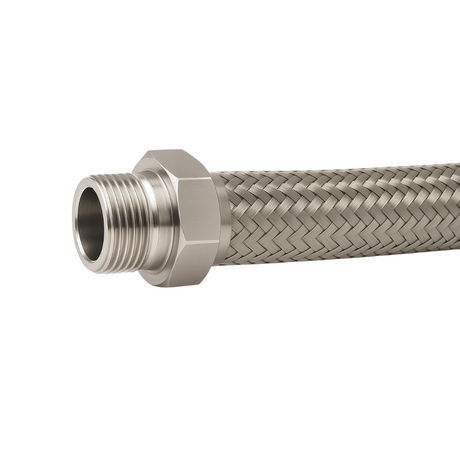

Regular price £0.00Unit price /UnavailableProFlow PTFE Hose with Stainless Steel RJT Male Fittings

Regular price £0.00Unit price /UnavailableProFlow PTFE Hose with Stainless Steel RJT Female Fittings

Regular price £0.00Unit price /UnavailableProFlow PTFE Hose with Stainless Steel BSP Male Fittings

Regular price £0.00Unit price /Unavailable- New arrival

ProFlow PTFE Hose with Stainless Steel Standpipe Fittings

Regular price £0.00Unit price /Unavailable - New arrival

Convoluted PTFE Hose with Stainless Steel Standpipe Fittings

Regular price £0.00Unit price /Unavailable Convoluted PTFE Hose with Stainless Steel Tri-Clamp Fittings

Regular price £0.00Unit price /UnavailableConvoluted PTFE Hose with Stainless Steel SMS Female Fittings

Regular price £0.00Unit price /UnavailableConvoluted PTFE Hose with Stainless Steel RJT Male Fittings

Regular price £0.00Unit price /UnavailableConvoluted PTFE Hose with Stainless Steel RJT Female Fittings

Regular price £0.00Unit price /UnavailableConvoluted PTFE Hose with Stainless Steel BSP Male Fittings

Regular price £0.00Unit price /UnavailableSmoothbore PTFE Hose with Stainless Steel Tri-Clamp Fittings

Regular price £0.00Unit price /UnavailableSmoothbore PTFE Hose with Stainless Steel SMS Female Fittings

Regular price £0.00Unit price /UnavailableSmoothbore PTFE Hose with Stainless Steel RJT Male Fittings

Regular price £0.00Unit price /UnavailableSmoothbore PTFE Hose with Stainless Steel RJT Female Fittings

Regular price £0.00Unit price /UnavailableSmoothbore PTFE Hose with Stainless Steel BSP Male Fittings

Regular price £0.00Unit price /Unavailable- New arrival

Smoothbore PTFE Hose with Stainless Steel Standpipe Fittings

Regular price £0.00Unit price /Unavailable

Not sure which hose is right for your application?

Speak to an Expert Today!

Interested in a Quote?

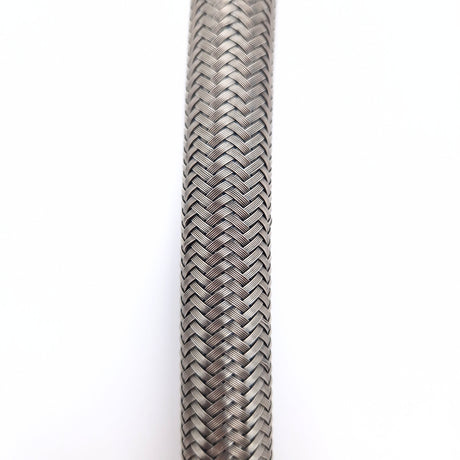

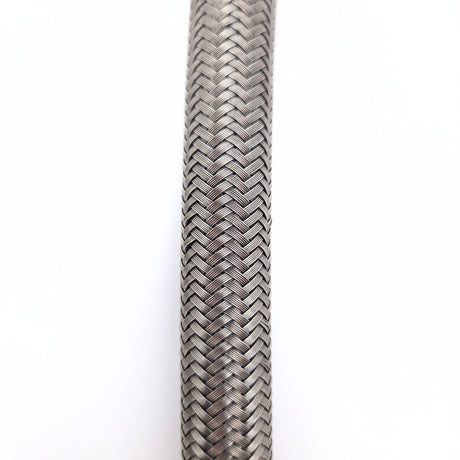

About Our PTFE Hoses