Yes. We supply hoses fully assembled to your exact specification, ready for immediate installation and use.

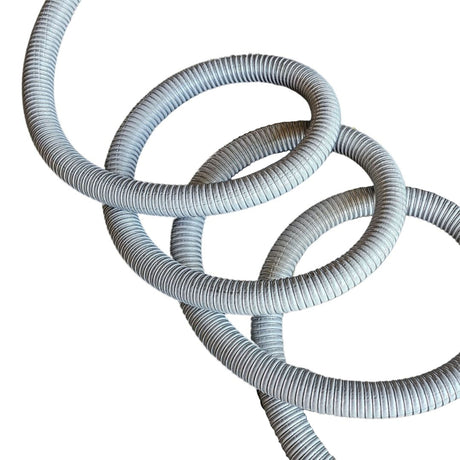

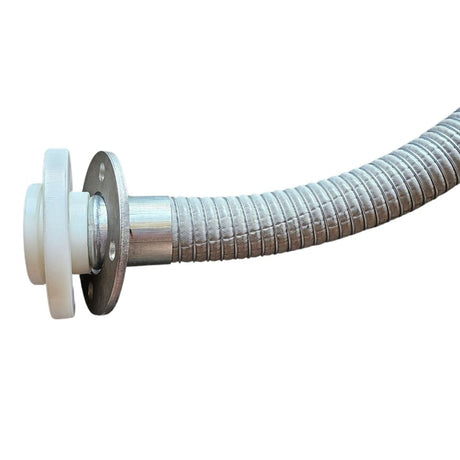

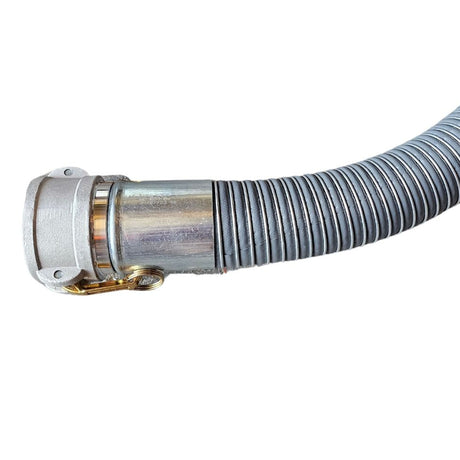

Our in-house hose assembly service allows us to build complete hose assemblies to suit your application, including hose type, bore size, length, and end connections. Assemblies can be supplied with a wide range of fittings, adapters, and connectors, including threaded, flanged, camlock, hygienic, and specialist fittings.

Where required, we can also carry out custom fabrication and welding to create bespoke adapters or transitions for unusual or legacy systems. This ensures compatibility with existing pipework, machinery, or tanker connections, reducing downtime and installation issues.

Each assembly is produced by experienced technicians and checked to ensure it meets the demands of the intended application.