Grey Composite Hose Assembly with Polyprop Table D Flanges

Contact

Contact

If you’d prefer to speak directly with an expert, our team is available to assist you by phone during business hours on 01406 362978.

Alternatively, you can email your enquiry to sales@jmlhenderson.co.uk and we’ll get back to you as promptly as possible.

Delivery

Delivery

We aim to dispatch all orders the same day, ensuring you receive your goods as quickly and efficiently as possible.

To provide reliable coverage, we use a trusted mix of Royal Mail, DPD, DX Freight and pallet network services, selecting the most suitable carrier based on order size, weight and delivery urgency.

We’re committed to reducing our environmental impact by using eco-friendly packaging solutions wherever possible, without compromising on protection or quality.

Domestic and international shipping options are available.

FAQ

FAQ

Our FAQ page covers common topics including ordering, delivery, returns, and product information. If you need further assistance, our team is always happy to help.

Description

Description

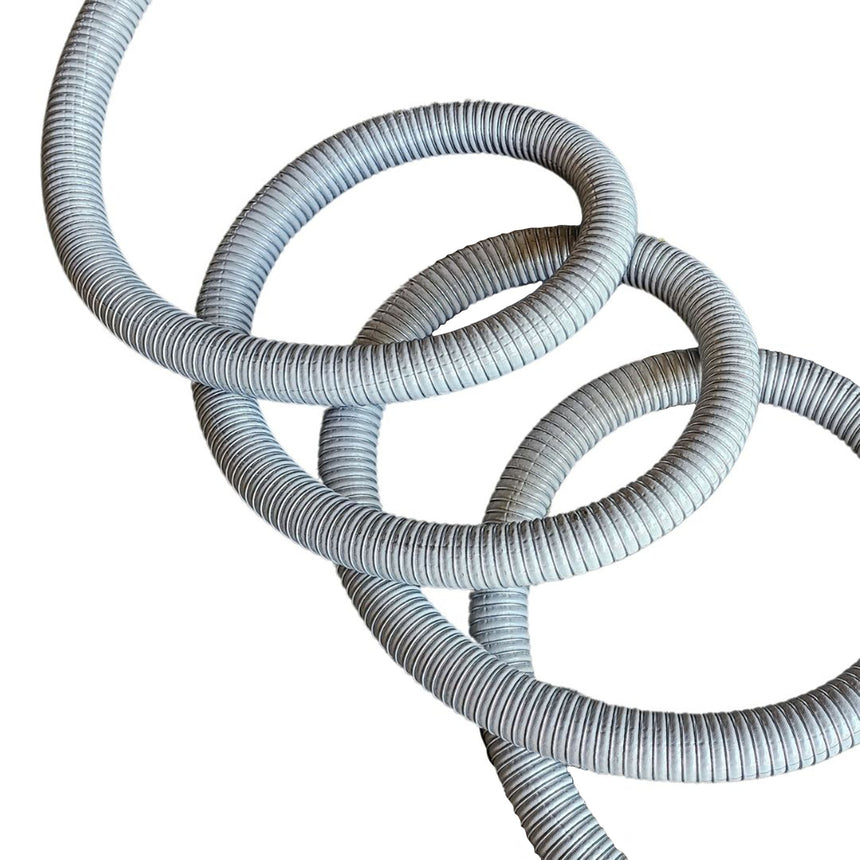

This flexible chemical transfer hose is built for demanding industrial environments. It uses a multi-layer composite construction of polypropylene fabrics and films with a weather-resistant, abrasion-resistant grey outer cover. The hose is reinforced with a polypropylene-coated inner wire and a galvanised external wire for strength and safety.

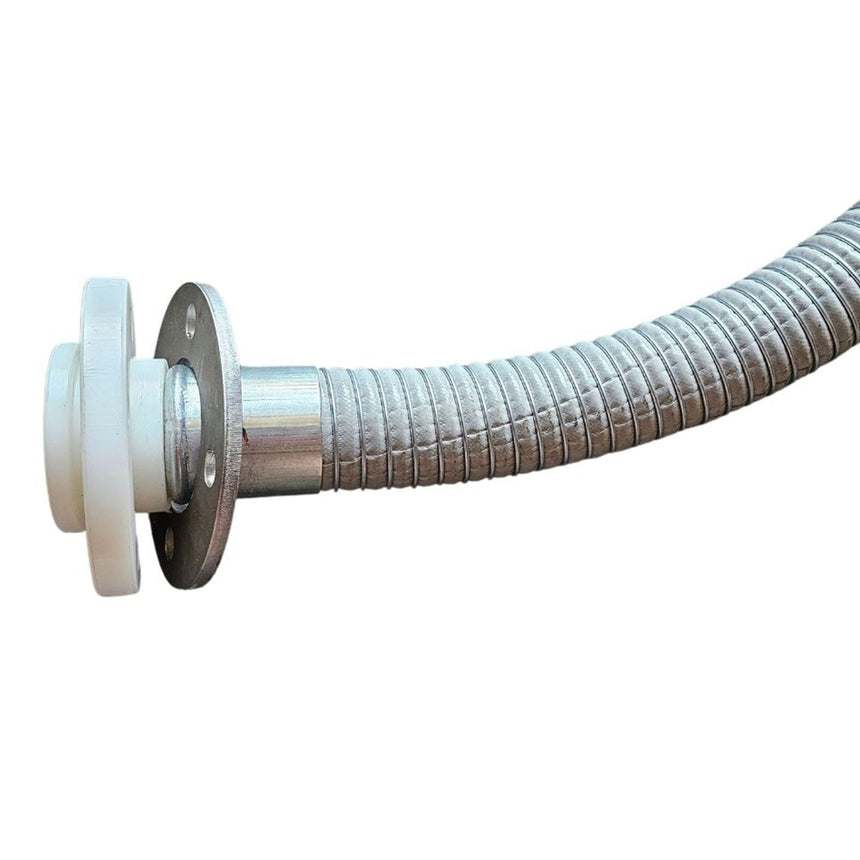

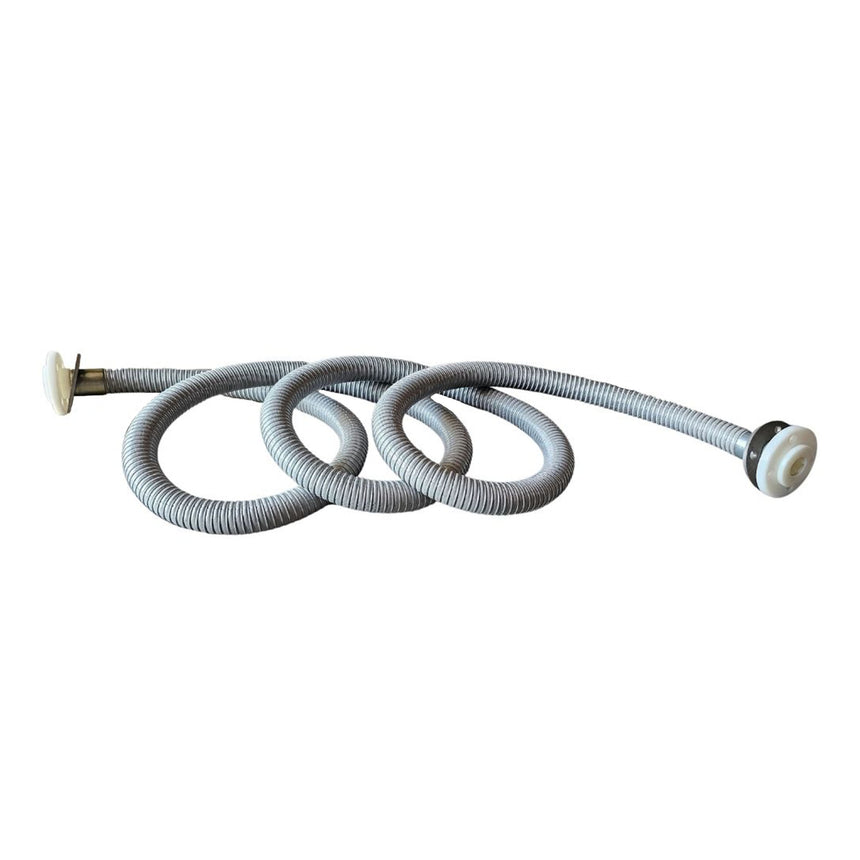

Supplied as standard with polypropylene Table D flanges for a secure, leak-resistant connection, this hose is ideal for road tanker loading and offloading or fixed plant installations where a robust, lightweight and reliable chemical transfer line is required.

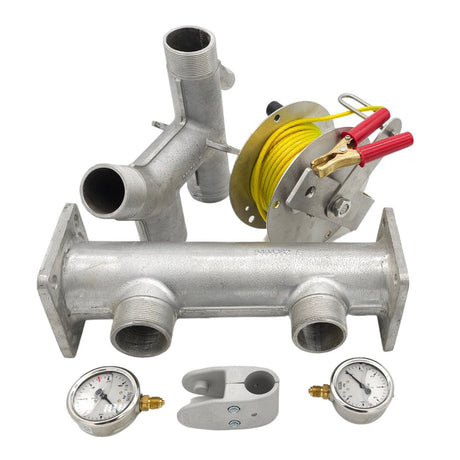

It is the standard general-purpose option within the composite hose range, suitable for most routine chemical transfer duties. For highly aggressive chemicals or higher temperatures, specialist constructions (such as PTFE-lined hoses) are also available.

(Stainless steel inner or outer wires can also be supplied for specialist applications on request.)

Key Features:

-

Durable composite build: Multi-layer polypropylene fabrics and films with galvanised external wire and polypropylene-coated inner wire for strength and chemical resistance.

-

Polypropylene Table D flanges: Provide a robust, corrosion-resistant bolted connection for secure installation in fixed plant or transfer systems.

-

General-purpose chemical use: Suitable for a wide range of chemicals, acids and alkalis in everyday transfer applications.

-

Pressure & length: Rated up to 14 bar (200 psi) working pressure. Supplied in any length up to 20m per coil, with alternative end fittings and custom assemblies available on request.

-

Wide temperature range: Operates from -30°C to +80°C to cover most chemical loading and offloading duties.

-

Abrasion and weather-resistant cover: Tough outer layer protects against wear and outdoor exposure.

-

Special builds available: Can be manufactured with stainless steel inner or outer wires for more aggressive applications.

Manufactured to EN 13765:2018 composite hose standards for chemical transfer. Suitable for full vacuum suction and discharge service.

Specifications

Specifications

-

Material

-

Temperature

-

Colour

Application

Application

Payment & Security

How to Order with JML Henderson Ltd

JML Henderson operates on a quotation-based ordering process to ensure every order is correctly specified and supplied.

Browse our website and submit a request for quotation for the products or hose assemblies you require. If you’re unsure what you need, our team is always happy to help, simply give us a call or send us an email.

Once your enquiry is received, our experienced team will review your requirements and provide a tailored quotation. When you’re happy to proceed, we’ll issue a proforma invoice for payment.

Payment can be made securely by bank transfer or card. As soon as payment is received, your order is released for immediate processing and dispatch.

Secure Payments

All payments are processed through secure payment systems. JML Henderson Ltd does not store or retain access to any card or payment details.