Not sure which Guillemin part you need?

Speak to an Expert Today!

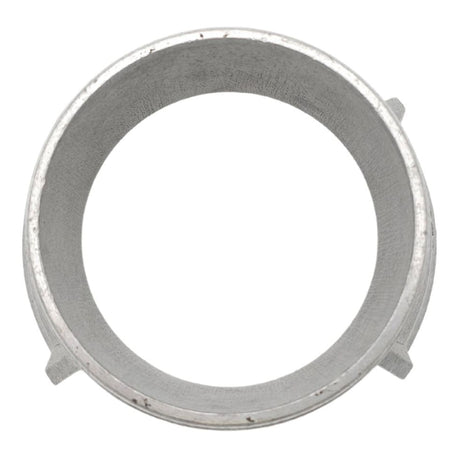

Guillemin Coupling to Serrated Hose Tail Without Claws (Aluminium)

Regular price £0.00Unit price /UnavailableGuillemin Coupling to BSP Male with Locking Ring (Stainless Steel)

Regular price £0.01Unit price /UnavailableGuillemin Coupling to BSP Female with Locking Ring (Stainless Steel)

Regular price £0.01Unit price /UnavailableGuillemin Coupling to BSP Male without Locking Ring (Aluminium)

Regular price £0.01Unit price /UnavailableGuillemin Coupling to BSP Male with Locking Ring (Aluminium)

Regular price £0.01Unit price /UnavailableGuillemin Coupling to BSP Female without Locking Ring (Aluminium)

Regular price £0.01Unit price /UnavailableGuillemin Coupling to BSP Female with Locking Ring (Aluminium)

Regular price £0.01Unit price /UnavailableGuillemin Coupling to Serrated Hose Tail (Aluminium)

Regular price £0.01Unit price /UnavailableGuillemin Coupling Reducer (Aluminium)

Regular price £0.01Unit price /UnavailableGuillemin Coupling Bung (Plastic)

Regular price £0.01Unit price /UnavailableGuillemin Coupling Blank Cap with Locking Ring (Stainless Steel)

Regular price £0.01Unit price /UnavailableGuillemin Coupling Blank Cap with Locking Ring and Chain (Aluminium)

Regular price £0.01Unit price /UnavailableGuillemin Coupling to 90° Bend (Aluminium)

Regular price £0.01Unit price /UnavailableGuillemin Coupling to Reducing 90° Bend (Aluminium)

Regular price £0.01Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

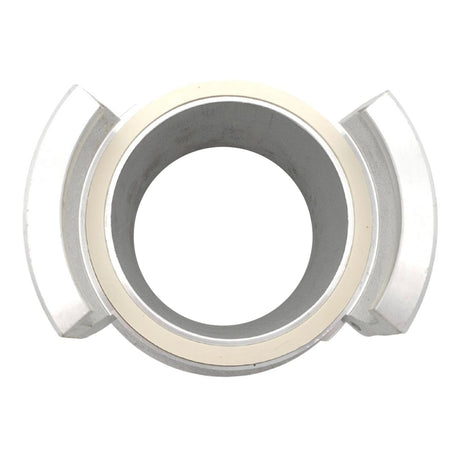

Guillemin Coupling Spanner (Mild Steel)

Regular price £0.01Unit price /Unavailable

Not sure which Guillemin part you need?

Speak to an Expert Today!

Interested in a Quote?

Advantages of using Guillemin

-

Symmetrical Design

uillemin couplings have a symmetrical design that allows for easy and quick connection without the need to align male and female parts. This feature simplifies the coupling process and saves time.

-

Ease of Use

These couplings can be connected and disconnected quickly and without tools, making them very user-friendly. This ease of use is beneficial in situations where fast setup and breakdown are essential.

-

Versatility

Guillemin couplings are available in various materials, including aluminum, stainless steel, and polypropylene, making them suitable for a wide range of applications such as water, oil, chemicals, and food products.

-

Leak-Proof Seal

The couplings provide a secure and leak-proof seal, which is crucial for preventing contamination and maintaining the integrity of the transferred substances. This reliability is especially important in industries such as food and pharmaceuticals.

-

Durability

Made from robust materials, Guillemin couplings are designed to withstand harsh conditions, high pressures, and abrasive materials. Their durability ensures a long service life and reduces the frequency of replacements.

-

Safety

The locking mechanism of Guillemin couplings enhances safety by preventing accidental disconnection. This safety feature is particularly valuable in high-pressure applications and when handling hazardous materials.

Guillemin couplings and fittings, also known as symmetrical or French couplings, are versatile and efficient components used to connect hoses and pipelines in fluid transfer systems. These couplings are designed with a unique symmetrical locking mechanism, allowing for easy and secure connections without the need for a specific alignment. Commonly used in industries like chemical processing, agriculture, and water management, Guillemin couplings are prized for their reliability and ease of use. Their robust design ensures leak-free connections, making them a trusted solution for handling liquids, powders, and gases.

Available in a range of sizes, Guillemin couplings accommodate various hose and pipe diameters, making them suitable for both small-scale and industrial applications. They are offered in durable materials such as stainless steel, plastic, and alloy, ensuring adaptability to different operating environments. Stainless steel Guillemin couplings are ideal for applications requiring high corrosion resistance and durability, such as chemical handling or marine systems. Plastic couplings provide a lightweight and economical option, suitable for non-corrosive and lower-pressure applications, while alloy couplings offer excellent strength and wear resistance, making them perfect for high-pressure or heavy-duty use.

The symmetrical design of Guillemin couplings allows for quick and tool-free connections, reducing downtime during assembly or maintenance. This feature makes them highly user-friendly and efficient, particularly in operations requiring frequent coupling and decoupling. Their robust construction ensures long-term performance, minimizing the risk of leaks or system failures. Whether used in transporting liquids, powders, or gases, Guillemin couplings deliver consistent reliability, and their availability in a range of sizes and materials ensures they can meet the diverse needs of industrial fluid handling systems.