Composite Chemical Hoses

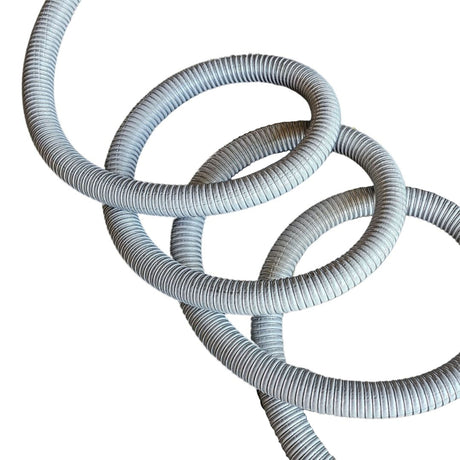

Composite hoses are flexible hoses used for a wide range of applications, including transferring liquids, gases, and solids. They are constructed from multiple layers of materials, which typically include an inner wire helix, multiple layers of fabric and film, and an outer wire helix.

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old

FiltersFilter & Sort

Blue Composite Oil Hose with BSP Female Ends

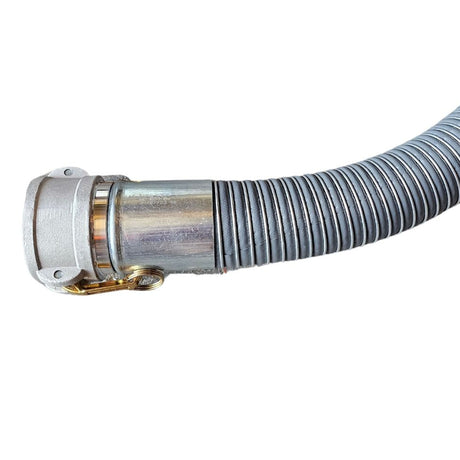

Regular price £0.00Unit price /UnavailableGrey Composite Hose Assembly with Camlock Females

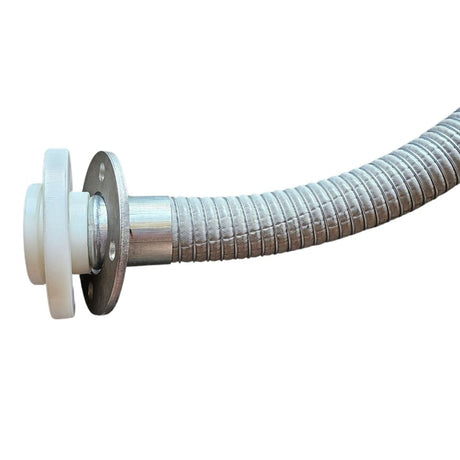

Regular price £0.00Unit price /UnavailableGrey Composite Hose Assembly with Polyprop Table D Flanges

Regular price £0.00Unit price /UnavailableGrey Composite Hose with BSP Female Ends

Regular price £0.00Unit price /Unavailable

Interested in a Quote?

View Our Industrial Hoses

Hose Couplings & Fittings

Hose couplings and fittings are essential components used to connect, adapt, or control the flow of fluid in various hose assemblies. These components can be found in a myriad of applications such as water supply, hydraulic systems, and industrial processes. Couplings come in different shapes, materials, and sizes - ranging from simple clamps and sleeves to more complex quick-connect or threaded fixtures.

Hose Clips & Clamps

Hose clips and clamps are mechanical devices specifically designed to secure hoses onto fittings, thereby preventing unwanted fluid leakage or detachment. These components are vital in various applications, such as automotive systems, industrial machinery, and plumbing. Made from materials like stainless steel, plastic, or even heavy-duty rubber, hose clips and clamps can range from simple wire forms to more elaborate quick-release or adjustable types.

Shop our Catalogue

- Hoses & Ducting

- Clips & Clamps

- Couplings & Fittings

- Tanker Parts

- Industrial Hoses

- Ducting Hoses

- PVC Hoses

- PTFE Hoses

- Hose Accessories

- Hose Manufacturers

- Clips & Clamps

- Clamp Material

- Manufacturers

- All Couplings & Fittings

- Unicone

- Bauer

- BSP

- Camlock

- Guillemin

- Lever Lock

- RJT

- DIN 11851

- Storz

- Tank Wagon

- Toggle

- URT

- Wilcox

- Hose Carriers

- Valves

- Aeration & Filters

- Bowls, Outlet & Discharge

- Tanker Body Parts

- Chassis Body Parts

- Engine Parts

-

Bulk Material Hoses

Bulk Material Hoses

-

Food Safe Hoses

Food Safe Hoses

-

Silo Vehicle Hoses

Silo Vehicle Hoses

-

Water & Liquid Hoses

Water & Liquid Hoses

-

Automotive Hoses

Automotive Hoses

-

Composite Hoses

Composite Hoses

-

Agricultural Hoses

Agricultural Hoses

-

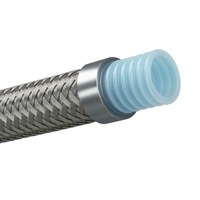

Stainless Steel Hoses

Stainless Steel Hoses

-

Abrasion Resistant (PU) Ducting

Abrasion Resistant (PU) Ducting

-

Anti-static Ducting

Anti-static Ducting

-

Food & Pharma Ducting

Food & Pharma Ducting

-

High Temperature Ducting

High Temperature Ducting

-

Ventilation Ducting

Ventilation Ducting

-

Suction & Delivery Hoses

Suction & Delivery Hoses

-

Wire Reinforced Hoses

Wire Reinforced Hoses

-

Braided & Tubing Hoses

Braided & Tubing Hoses

-

Layflat Hoses

Layflat Hoses

-

Smoothbore Hoses

Smoothbore Hoses

-

Convoluted Hoses

Convoluted Hoses

-

ProFlow (Hybrid) Hoses

ProFlow (Hybrid) Hoses

-

Anti-Scuff

Anti-Scuff

-

ID Tags

ID Tags

-

Whipcheck Safety Cables

Whipcheck Safety Cables

-

Alfagomma

Alfagomma

-

Continental

Continental

-

Copely

Copely

-

Gollmer & Hummel

Gollmer & Hummel

-

Griflex

Griflex

-

IVG

IVG

-

Masterflex

Masterflex

-

Thor

Thor

-

Trelleborg

Trelleborg

-

Band-it

Band-it

-

Constant Tension Clamps

Constant Tension Clamps

-

Ear 'O' Clips

Ear 'O' Clips

-

P-Clips

P-Clips

-

T Bolt Clamps

T Bolt Clamps

-

T Screw Clamps

T Screw Clamps

-

Worm Drive Clamps

Worm Drive Clamps

-

Safety Clamps

Safety Clamps

-

W1 - Mild Steel

W1 - Mild Steel

-

W2 - Part Stainless (430)

W2 - Part Stainless (430)

-

W3 - Full Stainless (430)

W3 - Full Stainless (430)

-

W4 - Full Stainless (304)

W4 - Full Stainless (304)

-

W5 - Full Stainless (316)

W5 - Full Stainless (316)

-

Mikalor

Mikalor

-

JCS

JCS

-

Norma

Norma

-

Unicone Couplings

Unicone Couplings

-

Bauer Couplings

Bauer Couplings

-

BSP Couplings

BSP Couplings

-

Camlock Couplings

Camlock Couplings

-

Geka Couplings

Geka Couplings

-

Guillemin Couplings

Guillemin Couplings

-

Instantaneous Couplings

Instantaneous Couplings

-

Lever Lock Couplings

Lever Lock Couplings

-

RJT Couplings

RJT Couplings

-

DIN 11851 Couplings

DIN 11851 Couplings

-

SMS Couplings

SMS Couplings

-

Storz Couplings

Storz Couplings

-

Tank Wagon Couplings

Tank Wagon Couplings

-

Toggle Couplings

Toggle Couplings

-

URT Couplings

URT Couplings

-

Wilcox Couplings

Wilcox Couplings

-

Unicone Blanks

Unicone Blanks

-

Unicone Clamps

Unicone Clamps

-

Unicone Hose Tails

Unicone Hose Tails

-

Unicone Elbows

Unicone Elbows

-

Unicone Adaptors

Unicone Adaptors

-

Unicone Seals

Unicone Seals

-

Unicone Threaded

Unicone Threaded

-

Unicone Weld On

Unicone Weld On

-

Unicone Parts

Unicone Parts

-

Bauer Blanks

Bauer Blanks

-

Bauer Hose Tails

Bauer Hose Tails

-

Bauer Adaptors

Bauer Adaptors

-

Bauer Bends

Bauer Bends

-

Bauer Seals

Bauer Seals

-

Bauer Weld On

Bauer Weld On

-

Bauer Strainers

Bauer Strainers

-

Bauer T-Pieces

Bauer T-Pieces

-

Bauer Y-Pieces

Bauer Y-Pieces

-

Bauer Parts

Bauer Parts

-

BSP Blanks

BSP Blanks

-

BSP Hose Tails

BSP Hose Tails

-

BSP Nipples

BSP Nipples

-

BSP Sockets

BSP Sockets

-

BSP Reducers

BSP Reducers

-

BSP Stubs

BSP Stubs

-

BSP Adaptors

BSP Adaptors

-

BSP Bends

BSP Bends

-

BSP Spanners

BSP Spanners

-

Camlock Blanks

Camlock Blanks

-

Camlock Hose Tails

Camlock Hose Tails

-

Camlock Adaptors

Camlock Adaptors

-

Camlock Reducers

Camlock Reducers

-

Camlock Seals

Camlock Seals

-

Camlock Parts

Camlock Parts

-

Guillemin Blanks

Guillemin Blanks

-

Guillemin Hose Tails

Guillemin Hose Tails

-

Guillemin Adaptors

Guillemin Adaptors

-

Guillemin Reducers

Guillemin Reducers

-

Guillemin Bends

Guillemin Bends

-

Guillemin Seals

Guillemin Seals

-

Guillemin Parts

Guillemin Parts

-

Lever Lock Blanks

Lever Lock Blanks

-

Lever Lock Hose Tails

Lever Lock Hose Tails

-

Lever Lock Adaptors

Lever Lock Adaptors

-

Lever Lock Bends

Lever Lock Bends

-

Lever Lock Reducers

Lever Lock Reducers

-

Lever Lock Weld On

Lever Lock Weld On

-

Lever Lock Threaded

Lever Lock Threaded

-

Lever Lock T Pieces

Lever Lock T Pieces

-

Lever Lock Seals

Lever Lock Seals

-

Lever Lock Parts

Lever Lock Parts

-

RJT Blanks

RJT Blanks

-

RJT Hose Tails

RJT Hose Tails

-

RJT Adaptors

RJT Adaptors

-

RJT Reducers

RJT Reducers

-

RJT Bends

RJT Bends

-

RJT Seals

RJT Seals

-

RJT Parts

RJT Parts

-

DIN 11851 Blanks

DIN 11851 Blanks

-

DIN 11851 Hose Tails

DIN 11851 Hose Tails

-

DIN 11851 Adaptors

DIN 11851 Adaptors

-

DIN 11851 Reducers

DIN 11851 Reducers

-

DIN 11851 Weld On

DIN 11851 Weld On

-

DIN 11851 Seals

DIN 11851 Seals

-

Storz Blanks

Storz Blanks

-

Storz Straps

Storz Straps

-

Storz Hose Tails

Storz Hose Tails

-

Storz Bends

Storz Bends

-

Storz Adaptors

Storz Adaptors

-

Storz Threaded

Storz Threaded

-

Storz Reducers

Storz Reducers

-

Storz Seals

Storz Seals

-

Storz Spanners

Storz Spanners

-

Storz Parts

Storz Parts

-

Tank Wagon Blanks

Tank Wagon Blanks

-

Tank Wagon VK Males

Tank Wagon VK Males

-

Tank Wagon MK Females

Tank Wagon MK Females

-

Tank Wagon Crowns

Tank Wagon Crowns

-

Tank Wagon Locking Rings

Tank Wagon Locking Rings

-

Tank Wagon Seals

Tank Wagon Seals

-

Tank Wagon Parts

Tank Wagon Parts

-

Toggle Blanks

Toggle Blanks

-

Toggle Hose Tails

Toggle Hose Tails

-

Toggle Bends

Toggle Bends

-

Toggle Weld On

Toggle Weld On

-

Toggle Seals

Toggle Seals

-

Toggle Parts

Toggle Parts

-

URT Hose Tails

URT Hose Tails

-

URT Adaptors

URT Adaptors

-

URT Reducers

URT Reducers

-

URT Weld On

URT Weld On

-

URT Seals

URT Seals

-

URT Parts

URT Parts

-

Wilcox Blanks

Wilcox Blanks

-

Wilcox Hose Tails

Wilcox Hose Tails

-

Wilcox Adaptors

Wilcox Adaptors

-

Wilcox Weld On

Wilcox Weld On

-

Wilcox Seals

Wilcox Seals

-

Wilcox Nuts

Wilcox Nuts

-

Wilcox Parts

Wilcox Parts

-

Hose Carrier Tubes

Hose Carrier Tubes

-

Hose Carrier Doors

Hose Carrier Doors

-

Hose Carrier Blanks

Hose Carrier Blanks

-

Hose Carrier Brackets

Hose Carrier Brackets

-

Hose Carrier Locks

Hose Carrier Locks

-

Hose Carrier Keys

Hose Carrier Keys

-

Hose Carrier Accessories

Hose Carrier Accessories

-

Air Shut Off Valves

Air Shut Off Valves

-

Ball Valves & Accelerators

Ball Valves & Accelerators

-

Butterfly Valves

Butterfly Valves

-

Diaphragm Valves

Diaphragm Valves

-

Gate Valves

Gate Valves

-

Non Return Valves

Non Return Valves

-

Pinch Valves

Pinch Valves

-

Pressure Relief Valves

Pressure Relief Valves

-

Universal Joints

Universal Joints

-

Aeration Pads

Aeration Pads

-

Aeration Socks

Aeration Socks

-

Aeration Valves

Aeration Valves

-

Air Filters

Air Filters

-

Compressor Filters

Compressor Filters

-

Vent Silencers

Vent Silencers

-

Discharge Elbows

Discharge Elbows

-

Drain Pots & Outlet Connection

Drain Pots & Outlet Connection

-

Flanges

Flanges

-

Manlid & Accessories

Manlid & Accessories

-

Material Line

Material Line

-

Sight Glasses

Sight Glasses

-

Accessories

Accessories

-

Air Manifold

Air Manifold

-

Anti Static & Earthing

Anti Static & Earthing

-

Gas Struts & Pneumatic Cylinders

Gas Struts & Pneumatic Cylinders

-

Gauges & Thermometers

Gauges & Thermometers

-

Handrail & Catwalk Parts

Handrail & Catwalk Parts

-

Information Holders

Information Holders

-

Lighting & Electronics

Lighting & Electronics

-

Load Security

Load Security

-

Locks & Catches

Locks & Catches

-

Sensors

Sensors

-

Air Tanks

Air Tanks

-

Axle Catch Ropes

Axle Catch Ropes

-

Bumpers, Brackets & LED

Bumpers, Brackets & LED

-

Landing Leg Brackets

Landing Leg Brackets

-

Mudguards & Brackets

Mudguards & Brackets

-

Side Guards

Side Guards

-

Tool Boxes

Tool Boxes

-

Air Filter Indicators

Air Filter Indicators

-

Control Panel

Control Panel

-

Drive Couplings & Clutches

Drive Couplings & Clutches

-

Electric Tip

Electric Tip

-

Engine Mountings

Engine Mountings

-

Fuel Tanks

Fuel Tanks

-

Hand Throttle

Hand Throttle

-

JCB & Yanmar

JCB & Yanmar

-

PTO / Hydraulic

PTO / Hydraulic

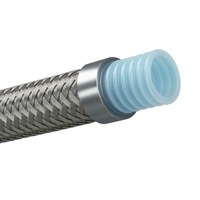

Composite Hoses

Composite hoses are unique types of hoses made up of multiple layers of materials, such as thermoplastics, metals, and fabrics. These layers are helically wound and bonded together to create a flexible, durable, and versatile hose. Composite hoses are widely used in various industries for transferring liquids, gases, and bulk materials. Here are some of the benefits of using composite hoses:

-

Versatility: Composite hoses can handle a wide range of substances, including chemicals, fuels, oils, and gases, making them suitable for various industries and applications.

-

Durability: The multi-layer construction of composite hoses makes them highly durable and resistant to abrasion, wear, and tear. They can withstand harsh operating conditions and have a long service life.

-

Chemical Resistance: Composite hoses are often used for chemical transfer due to their excellent resistance to a wide range of chemicals, including acids, alkalis, and solvents. The combination of materials used in their construction ensures compatibility with various substances.

-

Flexibility: Composite hoses are highly flexible, allowing for easy handling, installation, and routing in tight spaces or around obstacles. This flexibility also helps reduce stress on the hose and its connections, reducing the risk of damage or leaks.

-

Lightweight: Composite hoses are typically lighter than their metal or rubber counterparts, making them easier to handle, transport, and install. The reduced weight can also lead to cost savings in terms of transportation and installation.

-

Customization Options: Composite hoses are available in various sizes, materials, and configurations to meet specific application requirements. Custom options may include specialized couplings, liners, or covers to enhance performance or compatibility.

-

Safety: Properly designed and maintained composite hoses help prevent leaks, spills, and other hazards associated with fluid transfer. They can be equipped with safety features like antistatic wires or fire-resistant covers to enhance their safety in specific applications.

-

Temperature Resistance: Many composite hoses can handle a wide temperature range, making them suitable for applications with varying temperature requirements, such as hot or cold fluids.

-

Ease of Maintenance and Inspection: Composite hoses are typically easy to inspect and maintain. Their construction allows for visual inspection of the layers, helping to detect potential issues before they become severe.

-

Environmental Protection: By preventing leaks and spills, composite hoses help protect the environment from potential contamination. Their durability and long service life also reduce waste associated with frequent hose replacements.

It is essential to choose the appropriate composite hose for your specific application, considering factors such as the type of substance, operating pressure, high temperature, and installation requirements. Proper installation, maintenance, and regular inspections are also crucial to ensure the safe and efficient operation of composite hoses.

Subscribe to our emails

Be the first to know about our new products including hoses, couplings, clips, clamps & tanker parts.