Burgmer Metal to Metal Butterfly Valve

Regular price £0.00Unit price /UnavailableMetal to Metal Butterfly Valve

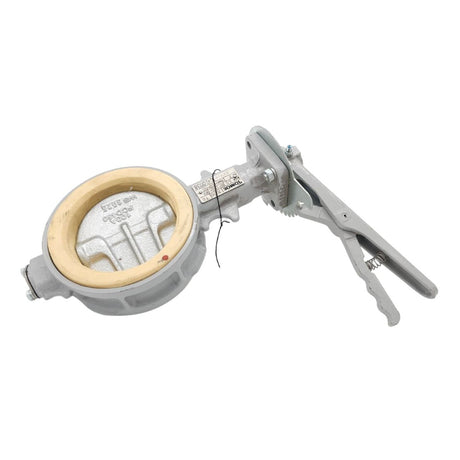

Regular price £0.01Unit price /UnavailableMetal to Metal Butterfly Valve with Trigger Handle

Regular price £0.01Unit price /Unavailable- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

3" Wide Butterfly Valve (Aluminium)

Regular price £0.00Unit price /UnavailableButterfly Valve Drilled (4 Hole)

Regular price £0.01Unit price /Unavailable- Regular price £0.01Unit price /Unavailable

Burgmer 14 Hole Spitzer Butterfly Valve 16mm Shaft

Regular price £0.01Unit price /Unavailable- Regular price £0.01Unit price /Unavailable

Ebro Z011-A Wafer Type Butterfly Valve

Regular price £0.01Unit price /Unavailable- Regular price £0.01Unit price /Unavailable

Burgmer Butterfly Valve with Handle (16mm Shaft)

Regular price £0.01Unit price /UnavailableBurgmer Butterfly Valve with Handle (12mm Shaft)

Regular price £0.01Unit price /Unavailable3" Wide Butterfly Valve Rubber Seat

Regular price £0.01Unit price /UnavailableBurgmer Butterfly Valve Seat (Rubber)

Regular price £0.01Unit price /UnavailableBurgmer Butterfly Valve Replacement Disc

Regular price £0.01Unit price /UnavailableEbro Butterfly Valve Replacement Handle (Plastic)

Regular price £0.01Unit price /UnavailableEbro Butterfly Valve Replacement Handle (Aluminium)

Regular price £0.01Unit price /UnavailableBurgmer Butterfly Valve Replacement Handle

Regular price £0.01Unit price /UnavailableBurgmer Butterfly Valve Replacement Handle DN150

Regular price £0.01Unit price /UnavailableBurgmer Butterfly Valve Replacement Handle DN200

Regular price £0.01Unit price /UnavailableTomoe Butterfly Valve Replacement Handle

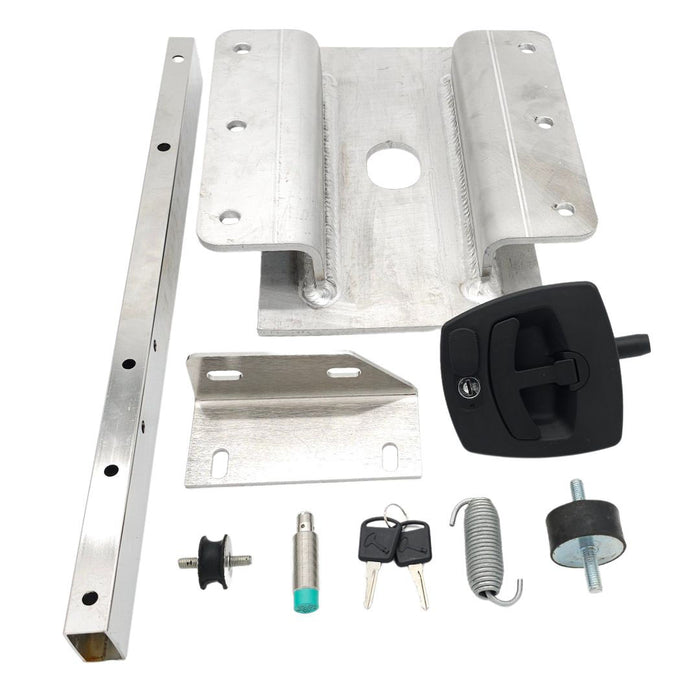

Regular price £0.01Unit price /Unavailable150mm Blank Flange 12 Hole (Aluminium)

Regular price £0.00Unit price /UnavailableButterfly Valve Blank 8 Hole Flange (Aluminium)

Regular price £0.00Unit price /UnavailableUniversal Joint Coupling for Butterfly Valve

Regular price £0.01Unit price /UnavailableSpitzer Butterfly Valve 2" (Stainless Steel)

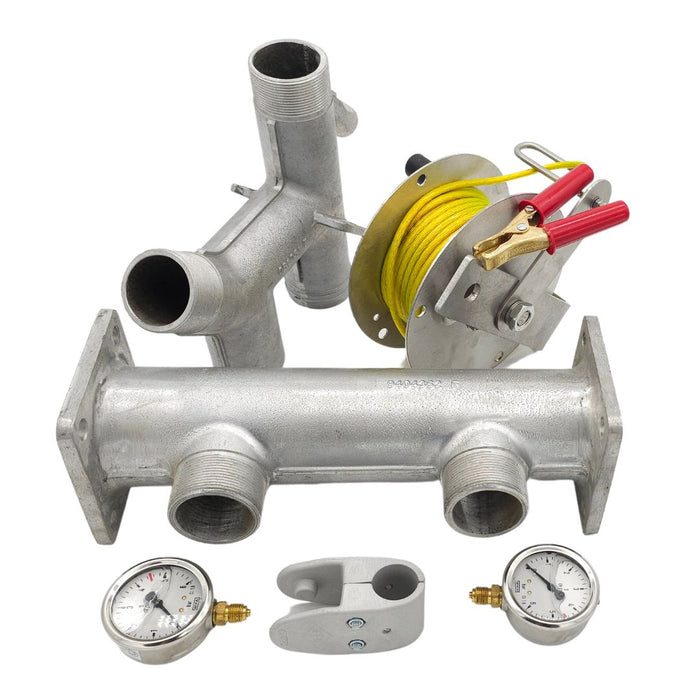

Regular price £0.01Unit price /UnavailableCombi Valve with BSP Females (Stainless Steel)

Regular price £0.01Unit price /UnavailableCombi Valve Handle (Blue Ball)

Regular price £0.00Unit price /UnavailableReplacement Blue Ball for Combi Valve

Regular price £0.00Unit price /UnavailableBurgmer 6 Hole Butterfly Valve

Regular price £0.01Unit price /Unavailable- New arrival

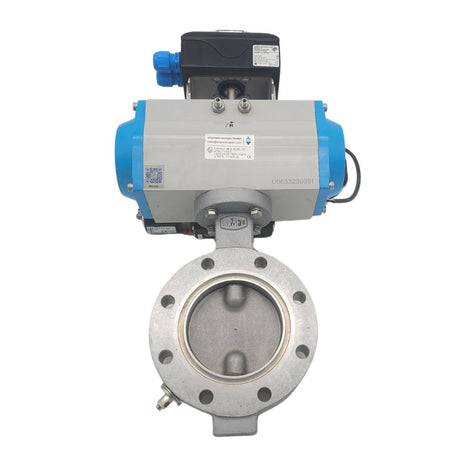

Burgmer 740 DM Butterfly Valve with Actuator

Regular price £0.00Unit price /Unavailable Burgmer Butterfly Valve with Handle (15mm Shaft)

Regular price £0.01Unit price /Unavailable

Butterfly valves are versatile and lightweight flow control devices used to regulate or isolate fluid flow in a wide variety of applications. These valves operate using a rotating disk as the closure mechanism, which pivots around a central axis to open, partially close, or fully block the flow path. Known for their compact design and ease of operation, butterfly valves are widely used in industries such as water treatment, HVAC, food and beverage, chemical processing, and power generation. Their ability to handle large flow rates while maintaining precise control makes them an essential component in fluid handling systems.

The key advantage of butterfly valves lies in their simple and efficient design, which minimizes weight and material usage compared to other types of valves. The disk, typically made from durable materials such as stainless steel, ductile iron, or plastic, is positioned in the center of the pipe and connected to an actuator on the outside of the valve body. Actuators may be manual (using a lever or gear) or automated (powered by pneumatic, electric, or hydraulic systems). This design allows for quick operation, making butterfly valves ideal for applications requiring frequent adjustments or fast shut-off.

Butterfly valves are available in various configurations, including wafer, lug, and double-flanged designs, to suit different installation and operational requirements. They are also offered in a range of materials and sizes, ensuring compatibility with diverse fluids, pressures, and temperatures. Easy to install and maintain, butterfly valves are a cost-effective solution for fluid management systems. Whether used for throttling or on/off flow control, their durability, versatility, and compact design make butterfly valves a popular choice across numerous industries, ensuring efficient and reliable system performance.Interested in a Quote?

Advantages of Using Butterfly Valves

-

Compact Design

-

Quick Operation

-

Energy Efficiency

-

Versatility

-

Low Maintenance

-

Tight Sealing