- £0.00Unit price /Unavailable

Full Bore Ball Valve (Stainless Steel)

£0.01Unit price /UnavailableNickel Plated Ball Valve (Brass)

£0.00Unit price /UnavailableRenus Ball Valve Replacement Handle (Aluminium)

£0.01Unit price /UnavailableRenus Accelerator Insert (Steel)

£0.01Unit price /Unavailable- £0.00Unit price /Unavailable

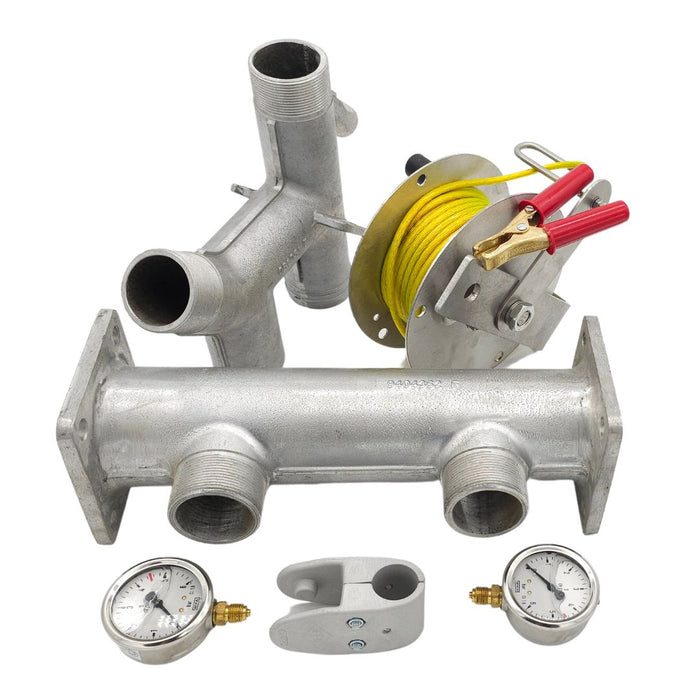

Ball Valve with Accelerator (Aluminium)

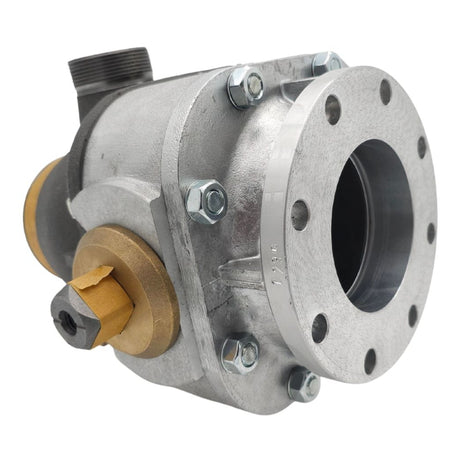

£0.00Unit price /UnavailableProkosch Ball Valve (Aluminium)

£0.00Unit price /UnavailableProkosch Ball Valve Flange (Aluminium)

£0.01Unit price /Unavailable- £0.01Unit price /Unavailable

Combi Valve with BSP Females (Stainless Steel)

£0.01Unit price /UnavailableFlanged Accelerator Insert (Steel)

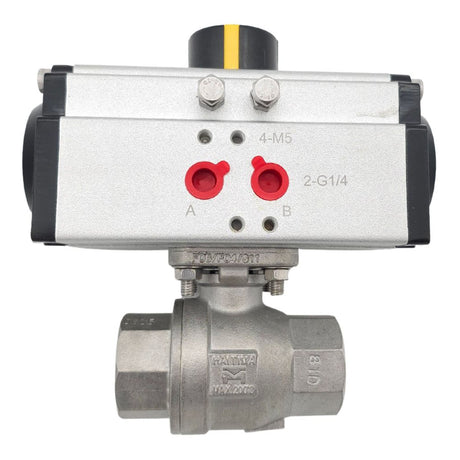

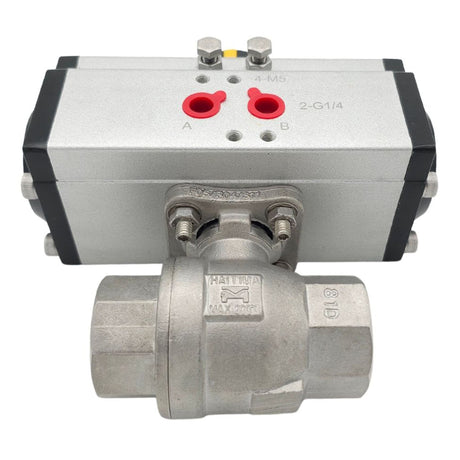

£0.00Unit price /UnavailableBall Valve with Double Acting Actuator

£0.00Unit price /Unavailable- £0.00Unit price /Unavailable

Ball valves are highly versatile and durable flow control devices used to regulate or shut off fluid flow in a wide range of applications. These valves feature a spherical closure element (the ball) with a hole through its center, which can be rotated to align with or block the flow path. Known for their reliability and ease of operation, ball valves are widely used in industries such as oil and gas, water management, chemical processing, and manufacturing. Their ability to provide a tight seal, even under high pressure and temperature, makes them a preferred choice for systems requiring precise flow control or complete shut-off.

Accelerators, in the context of fluid or pneumatic systems, are devices designed to boost the responsiveness or speed of valve actuation. They work in conjunction with ball valves and other control components to ensure rapid opening or closing, which is critical in applications where timing is crucial, such as in emergency shut-off systems or high-speed manufacturing processes. Accelerators help enhance the performance of ball valves by minimizing delays in response time, ensuring efficient operation and system reliability. This combination is particularly valuable in systems requiring precise coordination or high operational speed.

Together, ball valves and accelerators provide a powerful solution for efficient and responsive fluid management. The durability and simplicity of ball valves ensure long-term reliability, while the addition of accelerators improves their operational speed and adaptability in dynamic environments. This synergy is especially useful in applications involving high-pressure systems, rapid cycle operations, or emergency scenarios. By integrating these components, industries can optimize the performance, safety, and efficiency of their fluid handling systems, making ball valves and accelerators a versatile and effective choice for a wide range of applications.Interested in a Quote?

Advantages of Using Ball Valves

-

Excellent Shut-Off Capabilities

-

Durability and Longevity

-

Quick and Easy Operation

-

Low Maintenance

-

Versatile Use

-

Reduced Pressure Drop