- Regular price £0.00Unit price /Unavailable

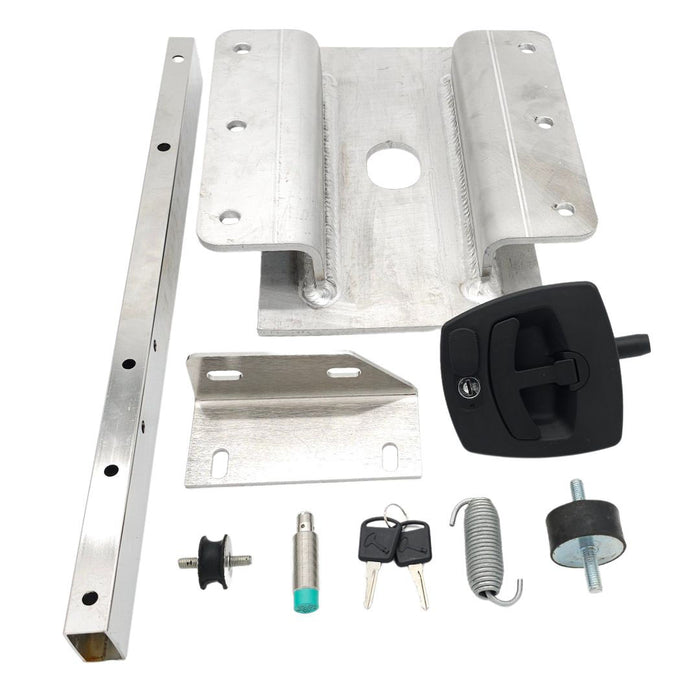

PN16 Gate Valve Handwheel Operated (Cast Iron)

Regular price £0.00Unit price /UnavailableBSP Gate Valve Handwheel Operated (Brass)

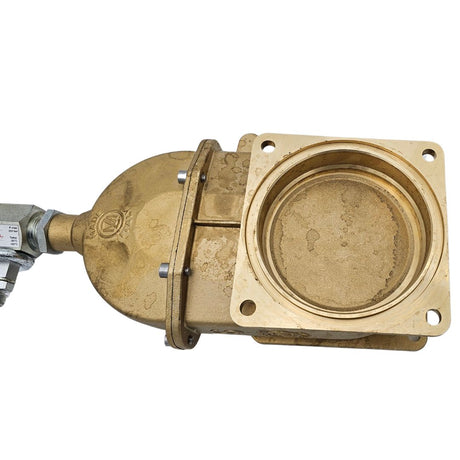

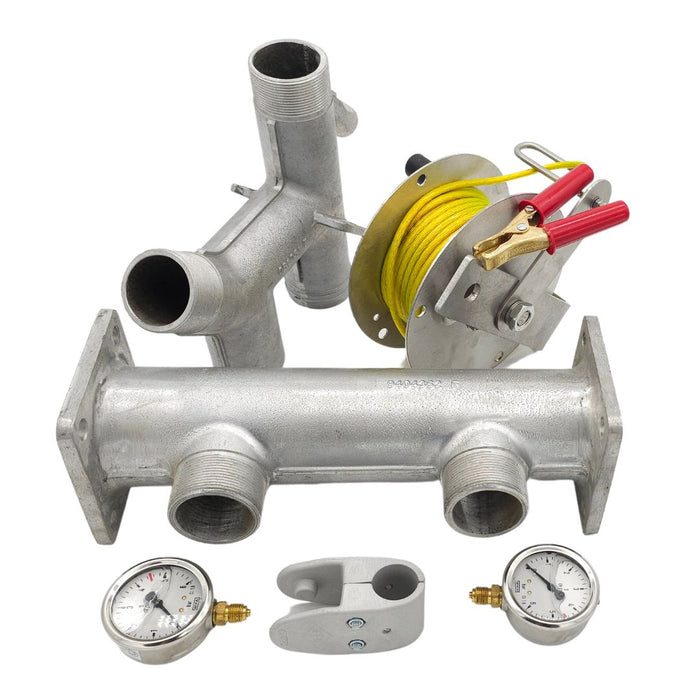

Regular price £0.00Unit price /UnavailableMZ Flange Gate Valve with Spring Hydraulic Actuator (Brass)

Regular price £0.00Unit price /UnavailableMZ Flange Gate Valve with Lever Handle (Brass)

Regular price £0.00Unit price /Unavailable

Gate valves are versatile and widely used flow control devices designed to regulate fluid flow by lifting or lowering a gate, typically a wedge or disk, to open or close the flow path. These valves are primarily used in applications where full, unobstructed flow or complete shut-off is required. Gate valves are common in industries such as water distribution, oil and gas, chemical processing, and power generation, where they are valued for their durability and ability to handle high-pressure and high-temperature conditions.

One of the key advantages of gate valves is their minimal flow resistance when fully open. The gate moves entirely out of the flow path, allowing for unobstructed fluid passage, which reduces pressure loss and energy consumption in the system. This makes gate valves particularly suitable for pipelines and systems that require low-pressure drop and infrequent operation, as they are not ideal for throttling purposes. The valves are available in various materials, including stainless steel, cast iron, brass, and ductile iron, ensuring compatibility with a wide range of fluids and operating environments.

Gate valves come in different configurations, such as rising stem and non-rising stem designs. Rising stem gate valves provide a visual indicator of the valve's position, making them easier to monitor, while non-rising stem gate valves are more compact and suitable for confined spaces. Available in a range of sizes and pressure ratings, gate valves are easy to install and maintain, offering reliable and long-lasting performance. Their ability to provide a tight seal and handle diverse operational conditions makes gate valves a trusted choice for professionals seeking robust and efficient fluid control solutions.Interested in a Quote?

Advantages of Using Gate Valves

-

Full Bore Design

-

Excellent Shut-Off Capabilities

-

Bi-Directional Flow Control

-

Durability and Longevity

-

Minimal Fluid Loss

-

Suitable for High-Pressures & High-Temperatures