- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

Solimar Fluidiser 1 Port (Clear)

Regular price £0.01Unit price /UnavailableSolimar Fluidiser 3 Port (Clear)

Regular price £0.01Unit price /UnavailableSolimar Fluidiser 2 Port (Clear)

Regular price £0.01Unit price /Unavailable- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

- Regular price £0.00Unit price /Unavailable

3/2 Way Valve with Push Button

Regular price £0.00Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

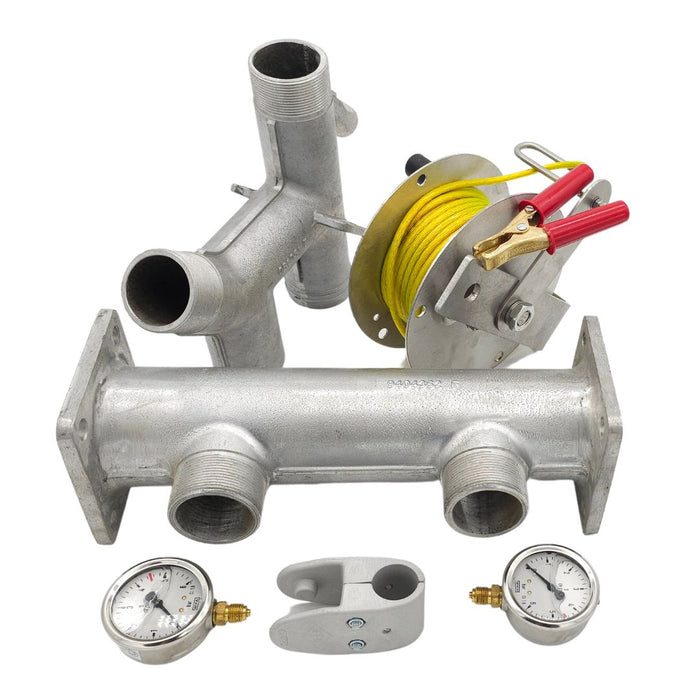

Solimar 3 Port Complete Assembly

Regular price £0.00Unit price /UnavailableSolimar 1 Port Complete Assembly

Regular price £0.00Unit price /UnavailableSolimar 2 Port Complete Assembly

Regular price £0.00Unit price /Unavailable

Aeration valves are critical components in bulk material handling systems, designed to regulate the flow of air used for aerating and fluidizing materials like powders, grains, and granules. These valves play a vital role in ensuring smooth and efficient material discharge from silos, hoppers, or bins, preventing blockages and maintaining consistent flow. Widely used in industries such as agriculture, food processing, cement production, and chemical manufacturing, aeration valves provide precise control over the aeration process, improving overall system performance and reliability.

The design of aeration valves typically includes a durable housing and a mechanism for controlling airflow, such as a diaphragm or a sliding gate. These valves allow operators to adjust the volume and pressure of air introduced into the system, ensuring optimal aeration based on the material's characteristics. Constructed from robust materials like stainless steel, aluminum, or high-grade plastics, aeration valves are built to withstand the rigors of demanding industrial environments, including exposure to abrasive materials and corrosive conditions.

Aeration valves are easy to install and integrate into existing systems, offering a practical and efficient solution for improving material flow. Regular inspection and maintenance, such as cleaning and checking for wear, ensure long-lasting performance and prevent issues like clogging or air leaks. By providing precise control over the aeration process, these valves help reduce material waste, minimize downtime, and enhance the productivity of bulk material handling operations. Their versatility and reliability make aeration valves an indispensable part of systems that handle fine, cohesive, or compacted materials.