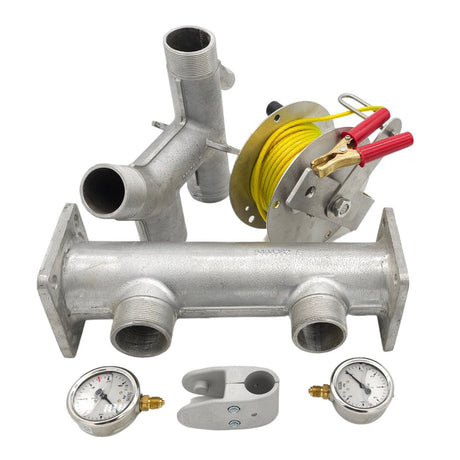

Vibrator Valve VT16

Couldn't load pickup availability

Get in Touch

Get in Touch

If you prefer to speak to someone directly, you can reach us via phone during our business hours. Simply dial 01406 362978, and one of our knowledgeable representatives will be ready to assist you.

Alternatively you can send us your query or request to sales@jmlhenderson.co.uk, and we will respond to you as promptly as possible.

Delivery

Delivery

When placing your order with us, rest assured that your items will be promptly shipped out using tracked, fastest-day delivery services. We prioritize efficient handling and secure shipping to ensure your package arrives swiftly and safely. Your satisfaction is our priority, and we strive to provide a seamless delivery experience from checkout to your doorstep.

FAQ

FAQ

Have questions? Check out our FAQ page for more information on a wide range of topics, from shipping and returns to product details and customer service inquiries. Click here to visit our FAQ page and find answers to commonly asked questions: FAQ Page. We're here to help make your shopping experience as smooth as possible.

A vibrator valve is a specialised type of industrial valve that incorporates a vibration mechanism to facilitate the flow of materials through the valve. It is typically used in applications where the flow of material can be hindered by blockages, bridging, or clumping, such as in the handling of dry bulk solids, powders, or granular materials. The valve's integrated vibrator helps to break up agglomerates, prevent material build up, and promote smooth and consistent flow.

Key Features:

-

Integrated Vibrator: Equipped with an internal or external vibrator mechanism that generates vibrations to assist in the flow of material through the valve.

-

Material Flow Assistance: Helps to break up material clumps, prevent blockages, and reduce the risk of material bridging or arching within the valve or downstream equipment.

-

Versatility: Suitable for a wide range of dry bulk materials, including powders, granules, pellets, and aggregates, and can be used in various industries, such as food, pharmaceuticals, chemicals, and construction.

-

Durable Construction: Typically constructed from robust materials such as stainless steel or carbon steel, which are resistant to wear, corrosion, and abrasion, ensuring long-lasting performance.

-

Variable Frequency and Amplitude: The vibrator's frequency and amplitude can usually be adjusted to suit the specific material characteristics and flow requirements of the application.

-

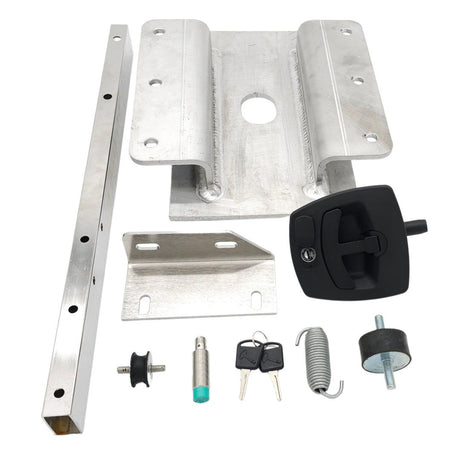

Easy Maintenance: Designed for simple disassembly and reassembly, making it easy to clean, maintain, and replace components as needed.

-

Efficient Operation: Helps to optimize the flow of material through the valve, improving overall process efficiency and reducing the risk of downtime due to material blockages or flow disruptions.

-

Customizable Designs: Available in various sizes, configurations, and materials to accommodate specific application requirements and process conditions.

-

Safety Features: Often equipped with safety features such as overload protection, thermal protection, and dust-tight or explosion-proof designs to ensure safe operation in various environments.

-

Sealing Mechanisms: Typically includes sealing mechanisms such as O-rings, gaskets, or packing to prevent material leakage and contamination.

Vibrator valves are an essential component in many bulk material handling systems, providing a reliable and efficient solution for managing the flow of dry bulk solids and powders. By reducing the risk of blockages, clumping, and material buildup, vibrator valves help to improve process efficiency, reduce maintenance requirements, and enhance overall system performance.

-

ProductAeration Valves

-

TypeValves

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.