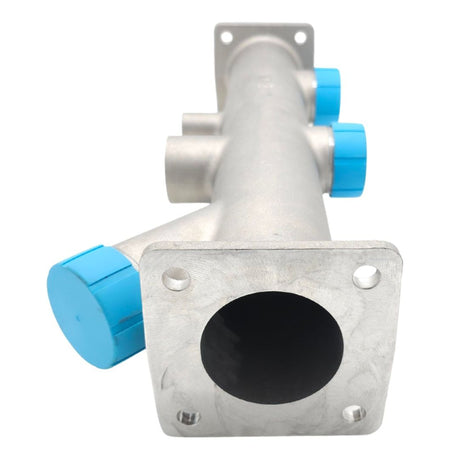

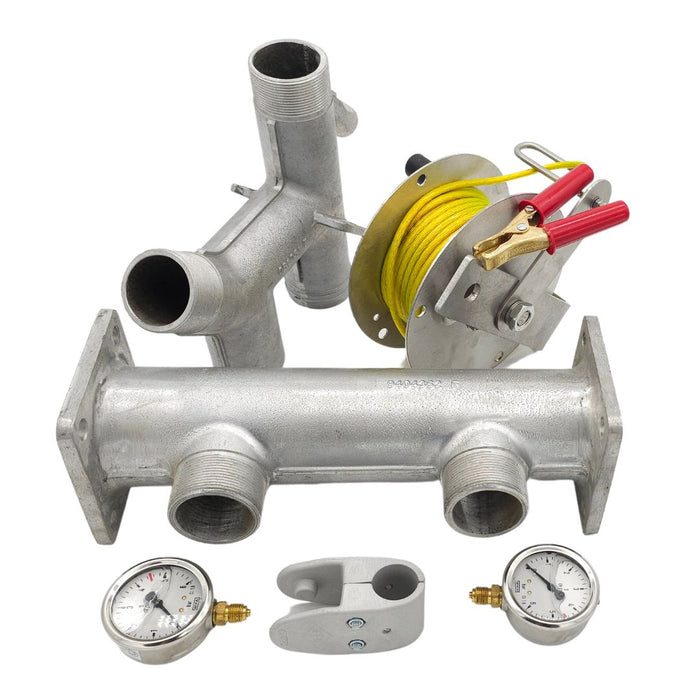

Air Manifold 2.5 Inch 1 Port Aluminium

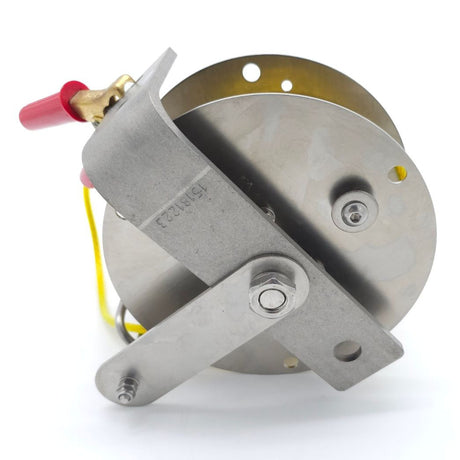

Regular price £0.01Unit price /UnavailableEarthing Reel Manual (Stainless Steel)

Regular price £0.01Unit price /Unavailable- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

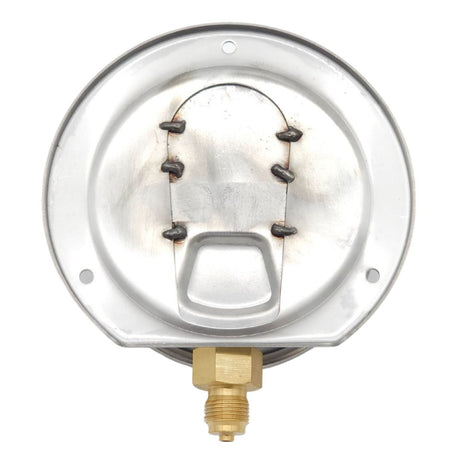

63mm Pressure Gauge 4 Bar Rear Entry 0.25" BSP

Regular price £0.01Unit price /Unavailable- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

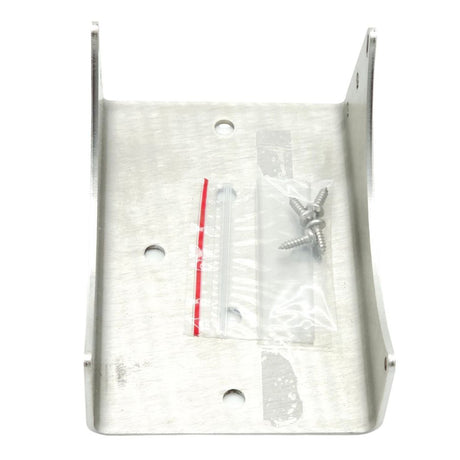

Earthing Reel Auto Return Cable (8m)

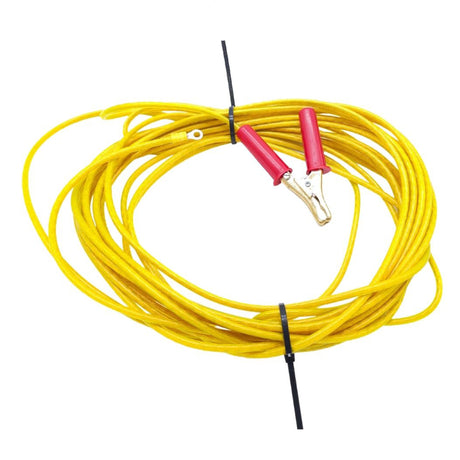

Regular price £0.01Unit price /UnavailableSpare Earthing Cable & Clip (15m)

Regular price £0.01Unit price /Unavailable- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

- Regular price £0.01Unit price /Unavailable

63mm Weigh Gauge 6 Bar Bottom Entry

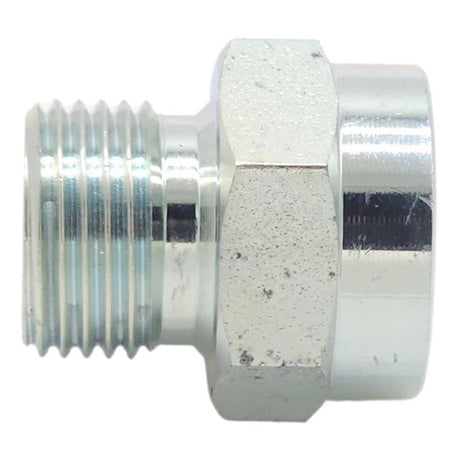

Regular price £0.01Unit price /UnavailableGauge Adapter 10L Female to 1/4" Female BSP

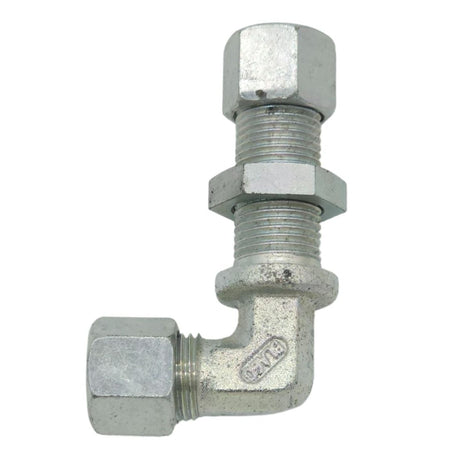

Regular price £0.01Unit price /Unavailable90° Elbow Connection Gauge M10

Regular price £0.01Unit price /Unavailable100mm WIKA Pressure Gauge 2.5 Bar Bottom Entry

Regular price £0.01Unit price /Unavailable63mm Temperature Gauges 300°C Rear Entry

Regular price £0.01Unit price /Unavailable63mm Temperature Gauge 300°C Bottom Entry

Regular price £0.01Unit price /Unavailable63mm Temperature Gauge 160°C Rear Entry

Regular price £0.01Unit price /Unavailable63mm Pressure Gauge 11 Bar Back Entry with Backplate

Regular price £0.01Unit price /Unavailable63mm Pressure Gauge 10 Bar 10mm Stem

Regular price £0.01Unit price /Unavailable63mm Pressure Gauge 7 Bar Bottom Entry

Regular price £0.01Unit price /Unavailable63mm Pressure Gauge 4 Bar Bottom Entry 0.5" BSP

Regular price £0.01Unit price /Unavailable63mm Pressure Gauge 4 Bar Rear Entry Flanged 0.25" BSP

Regular price £0.01Unit price /UnavailableAir Manifold With 2 Outlets and Top Air FFB

Regular price £0.01Unit price /UnavailableAir Manifold With 2 Outlets FFB

Regular price £0.01Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

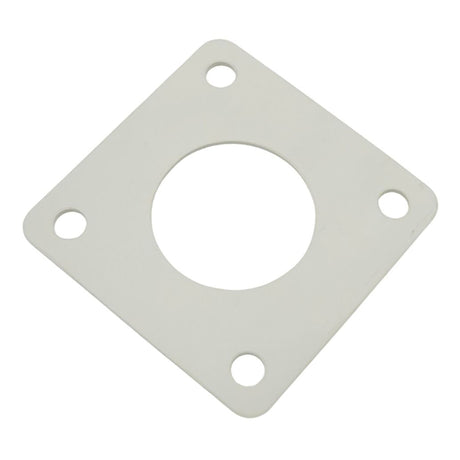

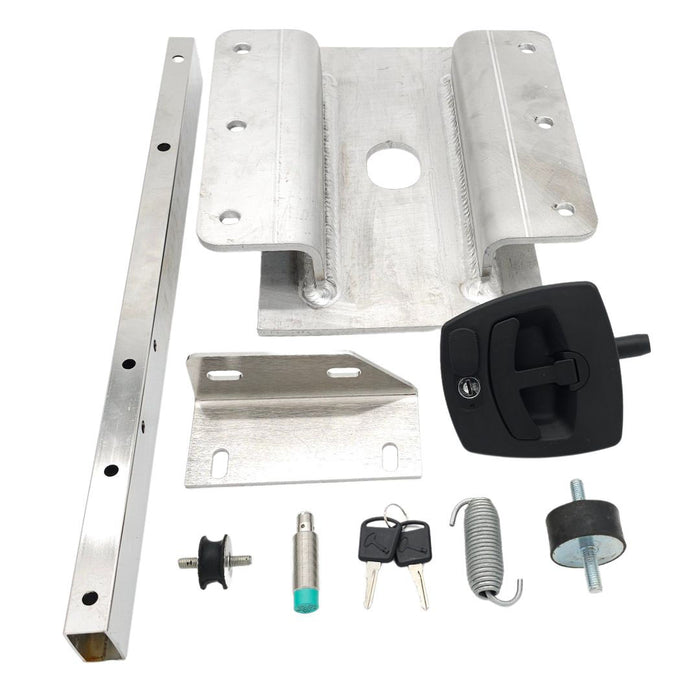

Manifold Square Flange 70mm Centre (Aluminium)

Regular price £0.00Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

- Regular price £0.00Unit price /Unavailable

- Regular price £0.00Unit price /Unavailable

- Regular price £0.00Unit price /Unavailable

Square Manifold Flange 90mm Centre (Aluminium)

Regular price £0.00Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

- Regular price £0.00Unit price /Unavailable

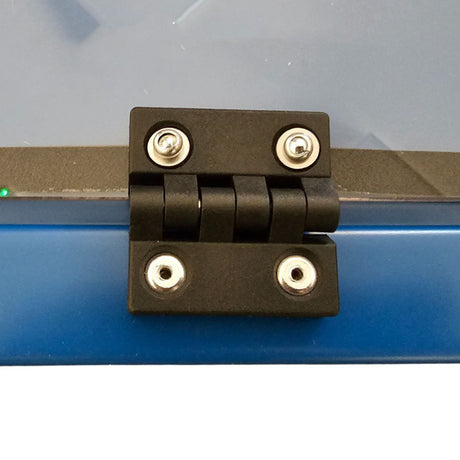

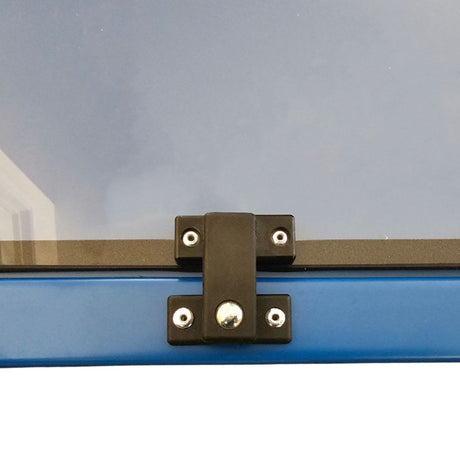

Camozzi 358-900 Manually Operated Lever Valve 5 2

Regular price £0.00Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

Rubber Hammer with Fibreglass Handle

Regular price £0.00Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

Lite-Wire Side Marker Lamp and Bracket

Regular price £0.00Unit price /Unavailable- Regular price £0.00Unit price /Unavailable

- Regular price £0.00Unit price /Unavailable

- Regular price £0.00Unit price /Unavailable