Lever Lock Weld On

(2 products)Lever Lock weld-on fittings are specialized components designed to create permanent, secure connections within a Lever Lock coupling system by welding them directly onto pipes, tanks, or equipment. These fittings are essential in applications where a robust, leak-proof, and long-lasting connection is required, ensuring that the Lever Lock coupling can be securely integrated into the system.

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old

FiltersFilter & Sort

Lever Lock Coupling Male to Weld On (Mild Steel)

Regular price £0.00Unit price /UnavailableLever Lock Coupling Female to Weld On (Mild Steel)

Regular price £0.00Unit price /Unavailable

Lever lock weld-ons are robust fittings designed to create permanent and secure connections in fluid transfer systems that utilize lever lock couplings. These weld-ons are engineered to be welded directly onto pipes or other metal components, providing a durable base for attaching lever lock couplings. Available in both male and female configurations, they are versatile and suitable for a wide range of applications in industries like agriculture, firefighting, and industrial fluid management. Lever lock weld-ons ensure a strong and leak-free connection, even in high-pressure environments.

Constructed from galvanized steel, lever lock weld-ons offer exceptional durability and resistance to corrosion, making them ideal for use in harsh environments or outdoor settings. The galvanized coating provides an added layer of protection against moisture, chemicals, and wear, ensuring long-lasting performance and reliability. These weld-ons come in a range of sizes, allowing compatibility with various pipe diameters and system configurations. Their robust design makes them suitable for both small-scale setups and large, industrial-scale systems.

Lever lock weld-ons are designed for ease of installation, with a weldable base that provides a secure foundation for the lever lock coupling mechanism. Once welded in place, they form a permanent and reliable connection, reducing the risk of leaks or disconnections over time. Their compatibility with lever lock couplings ensures quick and efficient assembly of fluid systems, while their sturdy construction allows them to withstand the rigors of demanding applications. By offering a variety of sizes and configurations, lever lock weld-ons provide a dependable solution for professionals seeking to build or upgrade fluid handling systems with durability and efficiency in mind.Interested in a Quote?

Advantages of Using Lever Lock Weld-On Fittings

-

Permanent and Secure Connections

Lever lock weld-on fittings are designed to be permanently welded to pipes or hoses, ensuring a secure and reliable bond. The weld creates a leak-proof, robust connection, making them ideal for high-pressure or heavy-duty applications where strong connections are critical.

-

Leak Prevention

Welded connections provide a tight, seamless seal, significantly reducing the risk of leaks in fluid or gas transfer systems. This leak-proof design is particularly important in high-pressure systems or environments where fluid containment is critical, such as in fuel transfer or chemical handling.

-

Minimal Maintenance

Once installed, lever lock weld-on fittings require minimal maintenance due to their robust construction and permanent connection. This reduces the need for frequent inspections, repairs, or replacements, contributing to more efficient and reliable system performance.

-

Enhanced Safety

Welded connections provide a high level of safety in fluid and gas transfer systems by ensuring that hoses or pipes remain securely connected. This is especially important in high-pressure or hazardous environments where leaks or accidental disconnections could pose significant risks to both equipment and personnel.

-

Compatibility with Lever Lock Systems

Lever lock weld-on fittings are designed to integrate seamlessly with standard lever lock couplings, ensuring reliable and secure connections. This compatibility simplifies system setup and expansion, ensuring a consistent and leak-free performance across the system.

-

Prevents Disconnections Under Pressure

The permanent weld ensures that the connection remains intact, even under high pressure or extreme conditions. This is crucial in preventing accidental disconnections, ensuring the continuous and safe operation of the system..

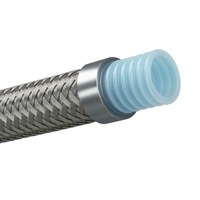

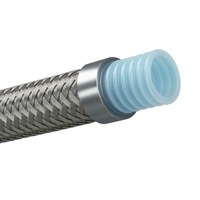

Industrial Hoses

Industrial hoses are robust, flexible tubes designed to convey fluids, gases, or granular materials under varying conditions and pressures. These hoses are employed across a diverse range of industries, including petrochemical, food processing, construction, and manufacturing, to name just a few. Made from materials such as rubber, PVC, or metal, they can be reinforced with layers of textile, wire, or other synthetic materials for added strength and durability.

Clips & Clamps

Hose clips and clamps are mechanical devices specifically designed to secure hoses onto fittings, thereby preventing unwanted fluid leakage or detachment. These components are vital in various applications, such as automotive systems, industrial machinery, and plumbing. Made from materials like stainless steel, plastic, or even heavy-duty rubber, hose clips and clamps can range from simple wire forms to more elaborate quick-release or adjustable types.

Shop our Catalogue

- Hoses & Ducting

- Clips & Clamps

- Couplings & Fittings

- Tanker Parts

- Industries

- Assembly

- Industrial Hoses

- Ducting Hoses

- PVC Hoses

- PTFE Hoses

- Hose Accessories

- Hose Manufacturers

- Clips & Clamps

- Clamp Material

- Manufacturers

- All Couplings & Fittings

- Unicone

- Bauer

- BSP

- Camlock

- Guillemin

- Lever Lock

- RJT

- DIN 11851

- Storz

- Tank Wagon

- Toggle

- URT

- Wilcox

- All Tanker Parts

- Hose Carriers

- Valves

- Aeration & Filters

- Bowls, Outlet & Discharge

- Tanker Body Parts

- Chassis Body Parts

- Engine Parts

- Industries We Serve

- Transport & Tankers

- Food & Beverage

- Construction & Quarrying

- Agricultural & Farming

- Chemical & Pharma

- Water & Utilities

- Waste & Environment

- Oil & Fuel

- Automotive

- Hose Assembly

- ID Tagging & Traceability

- Certification & Testing

- Inspection & Maintenance

-

Bulk Material Hoses

Bulk Material Hoses

-

Food Safe Hoses

Food Safe Hoses

-

Silo Vehicle Hoses

Silo Vehicle Hoses

-

Water & Liquid Hoses

Water & Liquid Hoses

-

Automotive Hoses

Automotive Hoses

-

Composite Hoses

Composite Hoses

-

Agricultural Hoses

Agricultural Hoses

-

Stainless Steel Hoses

Stainless Steel Hoses

-

Abrasion Resistant (PU) Ducting

Abrasion Resistant (PU) Ducting

-

Anti-static Ducting

Anti-static Ducting

-

Food & Pharma Ducting

Food & Pharma Ducting

-

High Temperature Ducting

High Temperature Ducting

-

Ventilation Ducting

Ventilation Ducting

-

Suction & Delivery Hoses

Suction & Delivery Hoses

-

Wire Reinforced Hoses

Wire Reinforced Hoses

-

Braided & Tubing Hoses

Braided & Tubing Hoses

-

Layflat Hoses

Layflat Hoses

-

Smoothbore Hoses

Smoothbore Hoses

-

Convoluted Hoses

Convoluted Hoses

-

ProFlow (Hybrid) Hoses

ProFlow (Hybrid) Hoses

-

Anti-Scuff

Anti-Scuff

-

ID Tags

ID Tags

-

Whipcheck Safety Cables

Whipcheck Safety Cables

-

Alfagomma

Alfagomma

-

Continental

Continental

-

Copely

Copely

-

Gollmer & Hummel

Gollmer & Hummel

-

Griflex

Griflex

-

IVG

IVG

-

Masterflex

Masterflex

-

Thor

Thor

-

Trelleborg

Trelleborg

-

Band-it

Band-it

-

Constant Tension Clamps

Constant Tension Clamps

-

Ear 'O' Clips

Ear 'O' Clips

-

P-Clips

P-Clips

-

T Bolt Clamps

T Bolt Clamps

-

T Screw Clamps

T Screw Clamps

-

Worm Drive Clamps

Worm Drive Clamps

-

Safety Clamps

Safety Clamps

-

W1 - Mild Steel

W1 - Mild Steel

-

W2 - Part Stainless (430)

W2 - Part Stainless (430)

-

W3 - Full Stainless (430)

W3 - Full Stainless (430)

-

W4 - Full Stainless (304)

W4 - Full Stainless (304)

-

W5 - Full Stainless (316)

W5 - Full Stainless (316)

-

Mikalor

Mikalor

-

JCS

JCS

-

Norma

Norma

-

Unicone Couplings

Unicone Couplings

-

Bauer Couplings

Bauer Couplings

-

BSP Couplings

BSP Couplings

-

Camlock Couplings

Camlock Couplings

-

Geka Couplings

Geka Couplings

-

Guillemin Couplings

Guillemin Couplings

-

Instantaneous Couplings

Instantaneous Couplings

-

Lever Lock Couplings

Lever Lock Couplings

-

RJT Couplings

RJT Couplings

-

DIN 11851 Couplings

DIN 11851 Couplings

-

SMS Couplings

SMS Couplings

-

Storz Couplings

Storz Couplings

-

Tank Wagon Couplings

Tank Wagon Couplings

-

Toggle Couplings

Toggle Couplings

-

URT Couplings

URT Couplings

-

Wilcox Couplings

Wilcox Couplings

-

Unicone Blanks

Unicone Blanks

-

Unicone Clamps

Unicone Clamps

-

Unicone Hose Tails

Unicone Hose Tails

-

Unicone Elbows

Unicone Elbows

-

Unicone Adaptors

Unicone Adaptors

-

Unicone Seals

Unicone Seals

-

Unicone Threaded

Unicone Threaded

-

Unicone Weld On

Unicone Weld On

-

Unicone Parts

Unicone Parts

-

Bauer Blanks

Bauer Blanks

-

Bauer Hose Tails

Bauer Hose Tails

-

Bauer Adaptors

Bauer Adaptors

-

Bauer Bends

Bauer Bends

-

Bauer Seals

Bauer Seals

-

Bauer Weld On

Bauer Weld On

-

Bauer Strainers

Bauer Strainers

-

Bauer T-Pieces

Bauer T-Pieces

-

Bauer Y-Pieces

Bauer Y-Pieces

-

Bauer Parts

Bauer Parts

-

BSP Blanks

BSP Blanks

-

BSP Hose Tails

BSP Hose Tails

-

BSP Nipples

BSP Nipples

-

BSP Sockets

BSP Sockets

-

BSP Reducers

BSP Reducers

-

BSP Stubs

BSP Stubs

-

BSP Adaptors

BSP Adaptors

-

BSP Bends

BSP Bends

-

BSP Spanners

BSP Spanners

-

Camlock Blanks

Camlock Blanks

-

Camlock Hose Tails

Camlock Hose Tails

-

Camlock Adaptors

Camlock Adaptors

-

Camlock Reducers

Camlock Reducers

-

Camlock Seals

Camlock Seals

-

Camlock Parts

Camlock Parts

-

Guillemin Blanks

Guillemin Blanks

-

Guillemin Hose Tails

Guillemin Hose Tails

-

Guillemin Adaptors

Guillemin Adaptors

-

Guillemin Reducers

Guillemin Reducers

-

Guillemin Bends

Guillemin Bends

-

Guillemin Seals

Guillemin Seals

-

Guillemin Parts

Guillemin Parts

-

Lever Lock Blanks

Lever Lock Blanks

-

Lever Lock Hose Tails

Lever Lock Hose Tails

-

Lever Lock Adaptors

Lever Lock Adaptors

-

Lever Lock Bends

Lever Lock Bends

-

Lever Lock Reducers

Lever Lock Reducers

-

Lever Lock Weld On

Lever Lock Weld On

-

Lever Lock Threaded

Lever Lock Threaded

-

Lever Lock T Pieces

Lever Lock T Pieces

-

Lever Lock Seals

Lever Lock Seals

-

Lever Lock Parts

Lever Lock Parts

-

RJT Blanks

RJT Blanks

-

RJT Hose Tails

RJT Hose Tails

-

RJT Adaptors

RJT Adaptors

-

RJT Reducers

RJT Reducers

-

RJT Bends

RJT Bends

-

RJT Seals

RJT Seals

-

RJT Parts

RJT Parts

-

DIN 11851 Blanks

DIN 11851 Blanks

-

DIN 11851 Hose Tails

DIN 11851 Hose Tails

-

DIN 11851 Adaptors

DIN 11851 Adaptors

-

DIN 11851 Reducers

DIN 11851 Reducers

-

DIN 11851 Weld On

DIN 11851 Weld On

-

DIN 11851 Seals

DIN 11851 Seals

-

Storz Blanks

Storz Blanks

-

Storz Straps

Storz Straps

-

Storz Hose Tails

Storz Hose Tails

-

Storz Bends

Storz Bends

-

Storz Adaptors

Storz Adaptors

-

Storz Threaded

Storz Threaded

-

Storz Reducers

Storz Reducers

-

Storz Seals

Storz Seals

-

Storz Spanners

Storz Spanners

-

Storz Parts

Storz Parts

-

Tank Wagon Blanks

Tank Wagon Blanks

-

Tank Wagon VK Males

Tank Wagon VK Males

-

Tank Wagon MK Females

Tank Wagon MK Females

-

Tank Wagon Crowns

Tank Wagon Crowns

-

Tank Wagon Locking Rings

Tank Wagon Locking Rings

-

Tank Wagon Seals

Tank Wagon Seals

-

Tank Wagon Parts

Tank Wagon Parts

-

Toggle Blanks

Toggle Blanks

-

Toggle Hose Tails

Toggle Hose Tails

-

Toggle Bends

Toggle Bends

-

Toggle Weld On

Toggle Weld On

-

Toggle Seals

Toggle Seals

-

Toggle Parts

Toggle Parts

-

URT Hose Tails

URT Hose Tails

-

URT Adaptors

URT Adaptors

-

URT Reducers

URT Reducers

-

URT Weld On

URT Weld On

-

URT Seals

URT Seals

-

URT Parts

URT Parts

-

Wilcox Blanks

Wilcox Blanks

-

Wilcox Hose Tails

Wilcox Hose Tails

-

Wilcox Adaptors

Wilcox Adaptors

-

Wilcox Weld On

Wilcox Weld On

-

Wilcox Seals

Wilcox Seals

-

Wilcox Nuts

Wilcox Nuts

-

Wilcox Parts

Wilcox Parts

-

Hose Carriers

Hose Carriers

-

Valves

Valves

-

Aeration & Filters

Aeration & Filters

-

Bowls, Outlet & Discharge

Bowls, Outlet & Discharge

-

Tanker Body Parts

Tanker Body Parts

-

Chassis Body Parts

Chassis Body Parts

-

Engine Parts

Engine Parts

-

Hose Carrier Tubes

Hose Carrier Tubes

-

Hose Carrier Doors

Hose Carrier Doors

-

Hose Carrier Blanks

Hose Carrier Blanks

-

Hose Carrier Brackets

Hose Carrier Brackets

-

Hose Carrier Locks

Hose Carrier Locks

-

Hose Carrier Keys

Hose Carrier Keys

-

Hose Carrier Accessories

Hose Carrier Accessories

-

Air Shut Off Valves

Air Shut Off Valves

-

Ball Valves & Accelerators

Ball Valves & Accelerators

-

Butterfly Valves

Butterfly Valves

-

Diaphragm Valves

Diaphragm Valves

-

Gate Valves

Gate Valves

-

Non Return Valves

Non Return Valves

-

Pinch Valves

Pinch Valves

-

Pressure Relief Valves

Pressure Relief Valves

-

Universal Joints

Universal Joints

-

Aeration Pads

Aeration Pads

-

Aeration Socks

Aeration Socks

-

Aeration Valves

Aeration Valves

-

Air Filters

Air Filters

-

Compressor Filters

Compressor Filters

-

Vent Silencers

Vent Silencers

-

Discharge Elbows

Discharge Elbows

-

Drain Pots & Outlet Connection

Drain Pots & Outlet Connection

-

Flanges

Flanges

-

Manlid & Accessories

Manlid & Accessories

-

Material Line

Material Line

-

Sight Glasses

Sight Glasses

-

Accessories

Accessories

-

Air Manifold

Air Manifold

-

Anti Static & Earthing

Anti Static & Earthing

-

Gas Struts & Pneumatic Cylinders

Gas Struts & Pneumatic Cylinders

-

Gauges & Thermometers

Gauges & Thermometers

-

Handrail & Catwalk Parts

Handrail & Catwalk Parts

-

Information Holders

Information Holders

-

Lighting & Electronics

Lighting & Electronics

-

Load Security

Load Security

-

Locks & Catches

Locks & Catches

-

Sensors

Sensors

-

Air Tanks

Air Tanks

-

Axle Catch Ropes

Axle Catch Ropes

-

Bumpers, Brackets & LED

Bumpers, Brackets & LED

-

Landing Leg Brackets

Landing Leg Brackets

-

Mudguards & Brackets

Mudguards & Brackets

-

Side Guards

Side Guards

-

Tool Boxes

Tool Boxes

-

Air Filter Indicators

Air Filter Indicators

-

Control Panel

Control Panel

-

Drive Couplings & Clutches

Drive Couplings & Clutches

-

Electric Tip

Electric Tip

-

Engine Mountings

Engine Mountings

-

Fuel Tanks

Fuel Tanks

-

Hand Throttle

Hand Throttle

-

JCB & Yanmar

JCB & Yanmar

-

PTO / Hydraulic

PTO / Hydraulic

View Our Couplings & Fittings

Subscribe to our emails

Be the first to know about our new products including hoses, couplings, clips, clamps & tanker parts.