Tanker hoses may not be the most glamorous component in industrial operations, but they are unquestionably one of the most vital. Used across an array of industries from petroleum and chemical to food and beverages, these hoses are the lifelines that enable the safe and efficient transport of liquids, gases, and even some solids. This blog post aims to shed light on the purpose and function of tanker hoses, helping you understand why they are an indispensable asset in various applications.

The Purpose of Tanker Hoses

- Safety: Tanker hoses are designed to be robust, durable, and secure to minimize the risk of spills or leaks that can lead to environmental hazards and financial loss.

- Versatility: These hoses can handle an array of substances, including corrosive chemicals, oils, gases, and food products, making them highly versatile for different industrial needs.

- Efficiency: Modern tanker hoses are engineered to facilitate a fast and smooth flow of materials, reducing the time taken for loading and unloading operations.

Material Matters: What Are They Made Of?

The construction material of a tanker hose depends on its application. Common materials include:

- Rubber: For water, certain chemicals, and food products.

- Composite: For oils and petrochemicals.

- PTFE (Polytetrafluoroethylene): For highly corrosive or high-temperature substances.

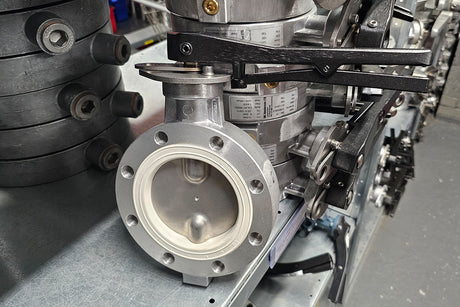

Key Functional Components

- Inner Tube: The inner tube comes in direct contact with the substance being conveyed and must be compatible with it to prevent degradation or contamination.

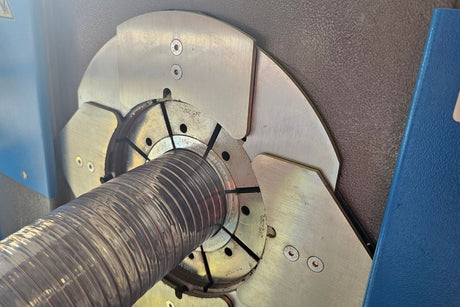

- Reinforcement: Layered between the inner tube and the outer cover, the reinforcement layer adds strength and flexibility to the hose.

- Outer Cover: This layer protects the hose from external elements like weather, abrasions, or corrosive substances.

Types of Tanker Hoses Based on Applications

- Oil and Fuel Tanker Hoses: These are designed with a focus on thermal stability, flexibility, and resistance to oil and chemicals.

- Chemical Tanker Hoses: Made from materials like PTFE or specialized rubber compounds, these hoses can withstand a wide range of corrosive chemicals.

- Food and Beverage Tanker Hoses: Designed to be non-toxic and compliant with food safety standards, these hoses are used for transporting consumable liquids like milk, wine, or oils.

- Gas Tanker Hoses: Engineered to handle gases, these hoses need to be extremely tight and usually feature specialized couplings to prevent leaks.

Best Practices for Using Tanker Hoses

- Regular Inspection: Check for wear, tear, and other signs of damage that may compromise the hose's integrity.

- Proper Storage: Store the hoses in a way that prevents bends or kinks, as these can weaken the structure over time.

- Compatibility Check: Always ensure that the hose material is compatible with the substance it is supposed to transport.

Conclusion

Tanker hoses are far more than just tubes for transferring materials; they are specialized equipment designed to meet stringent safety and performance criteria. Understanding the purpose and function of these hoses not only helps in selecting the right hose for your needs but also underscores the importance of proper maintenance and usage. Given their critical role in industrial applications, tanker hoses truly deserve our attention and understanding.