In industries where heavy machinery and piping systems are the norm, the safety of employees and the integrity of the equipment should always be a priority. One vital yet often overlooked component that contributes significantly to both is the safety clamp. Despite its modest appearance, a safety clamp is essential in securing hoses, pipes, and other conduits to prevent accidents and enhance the efficiency of various systems. This blog aims to offer a comprehensive understanding of safety clamps, their types, applications, and selection criteria.

What Are Safety Clamps?

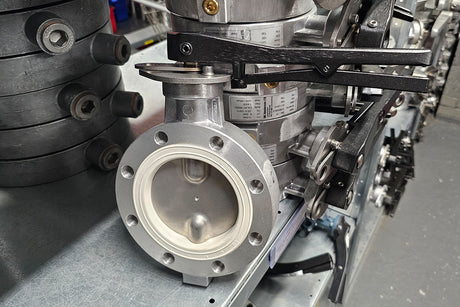

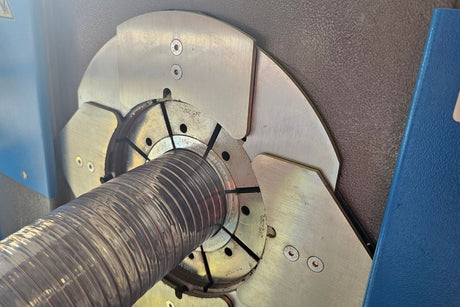

Safety clamps are mechanical devices designed to secure hoses, pipes, or tubes to a particular point. They are built to withstand different levels of pressure and are often made of materials like stainless steel, aluminum, or high-grade plastic. Their primary function is to prevent the dislocation or movement of pipes and hoses, ensuring a secure connection that mitigates the risks associated with high-pressure or volatile substances.

Applications of Safety Clamps

- Chemical Industry: In environments where hazardous chemicals are transferred through hoses, safety clamps ensure that there are no accidental spillages or leaks.

- Food and Beverage Industry: Safety clamps made of stainless steel or food-grade materials are used to secure hoses used in the transfer of edible items.

- Oil and Gas Industry: Safety clamps are essential in securing high-pressure hoses and pipes, ensuring safe and efficient operations.

- Construction Sites: In construction settings, safety clamps are often used to secure pneumatic hoses and other machinery components.

- Maritime and Offshore Applications: In offshore oil rigs or ships, safety clamps prevent the dislocation of hoses and pipes due to the constant movement and vibrations.

Criteria for Selecting Safety Clamps

- Material Compatibility: Choose a safety clamp made of material that is compatible with the substance being transferred through the hose or pipe.

- Pressure Rating: Ensure that the clamp can withstand the pressure levels of your specific application to avoid any failures or accidents.

- Size and Fit: Always measure the hose or pipe diameter to make sure the safety clamp will fit securely.

- Environmental Conditions: If the clamps will be exposed to corrosive substances or extreme temperatures, make sure they are designed to withstand such conditions.

- Industry Standards: Always choose safety clamps that meet or exceed industry safety standards. This ensures that the product has been rigorously tested for quality and durability.

Conclusion

Safety clamps may not be the most glamorous components in an industrial setting, but their importance cannot be overstated. They are critical in maintaining a safe and efficient environment, safeguarding both workers and equipment. Understanding the different types and their specific applications can help you make an informed choice that will serve both safety and functional needs. In industries where even the smallest oversight can result in catastrophic consequences, investing in high-quality safety clamps is not just a good practice; it's a necessity.