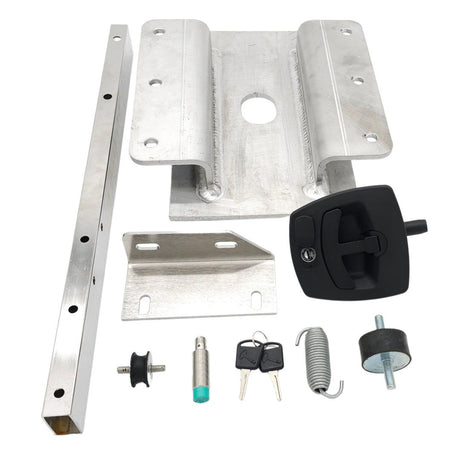

Lever Lock Coupling O-Ring Seal (Rubber)

Couldn't load pickup availability

Get in Touch

Get in Touch

If you prefer to speak to someone directly, you can reach us via phone during our business hours. Simply dial 01406 362978, and one of our knowledgeable representatives will be ready to assist you.

Alternatively you can send us your query or request to sales@jmlhenderson.co.uk, and we will respond to you as promptly as possible.

Delivery

Delivery

When placing your order with us, rest assured that your items will be promptly shipped out using tracked, fastest-day delivery services. We prioritize efficient handling and secure shipping to ensure your package arrives swiftly and safely. Your satisfaction is our priority, and we strive to provide a seamless delivery experience from checkout to your doorstep.

FAQ

FAQ

Have questions? Check out our FAQ page for more information on a wide range of topics, from shipping and returns to product details and customer service inquiries. Click here to visit our FAQ page and find answers to commonly asked questions: FAQ Page. We're here to help make your shopping experience as smooth as possible.

A Lever Lock Coupling O-Ring is an indispensable sealing component in lever lock couplings, essential for ensuring airtight and secure connections in various fluid handling systems. These O-Rings are typically manufactured from materials such as nitrile rubber, silicone, or Viton, selected for their specific properties to effectively withstand environmental conditions, chemicals, and temperatures they will encounter.

Designed to fit precisely within a groove in the lever lock coupling, the O-Ring forms a critical part of the connection. When the coupling is engaged, the O-Ring is compressed between the two halves, creating a robust seal that prevents leaks of fluids or gases. This compression must be carefully calibrated to achieve optimal sealing without causing excessive wear or deformation to the O-Ring, thereby ensuring longevity and reliability in its performance.

Lever Lock Coupling O-Rings are widely utilized across various industries, including agriculture for irrigation systems, firefighting, and industrial applications where quick and effective fluid connections are crucial. The functionality of these O-Rings directly impacts the efficiency and safety of these systems, making their design and material composition key to their success.

-

ProductLever Lock

-

TypeLever Lock Seal

-

Size

-

Connection 1

-

Connection 2

-

Material Type

-

Colour

Payment & Security

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.