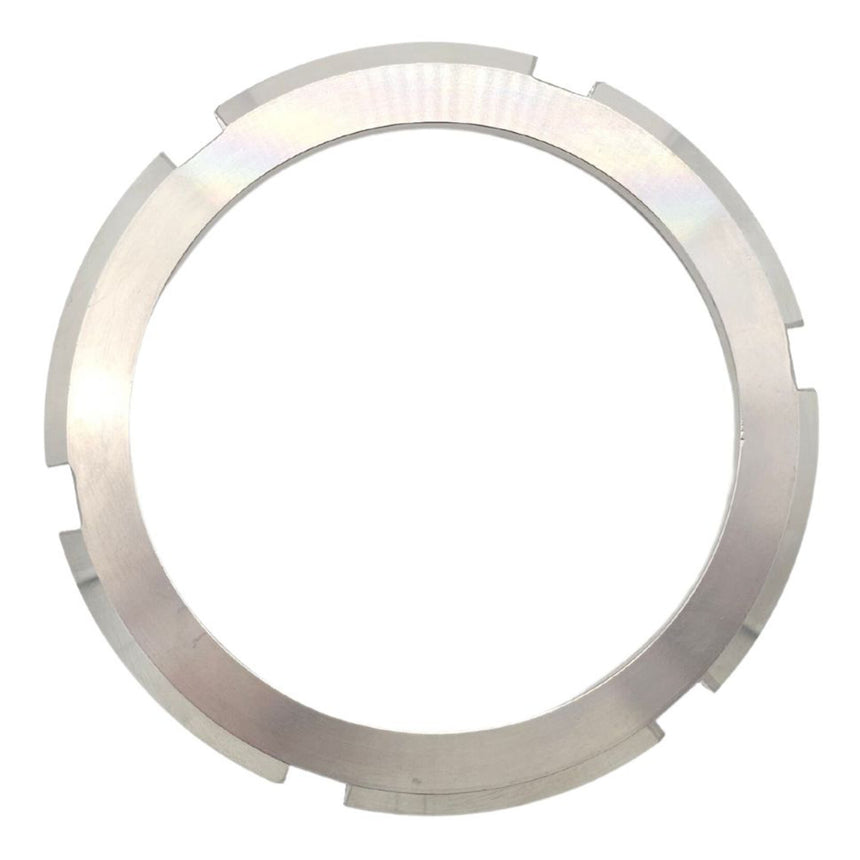

DIN 11851 Rosista Coupling Nut (Stainless Steel)

Contact

Contact

If you’d prefer to speak directly with an expert, our team is available to assist you by phone during business hours on 01406 362978.

Alternatively, you can email your enquiry to sales@jmlhenderson.co.uk and we’ll get back to you as promptly as possible.

Delivery

Delivery

We aim to dispatch all orders the same day, ensuring you receive your goods as quickly and efficiently as possible.

To provide reliable coverage, we use a trusted mix of Royal Mail, DPD, DX Freight and pallet network services, selecting the most suitable carrier based on order size, weight and delivery urgency.

We’re committed to reducing our environmental impact by using eco-friendly packaging solutions wherever possible, without compromising on protection or quality.

Domestic and international shipping options are available.

FAQ

FAQ

Our FAQ page covers common topics including ordering, delivery, returns, and product information. If you need further assistance, our team is always happy to help.

Description

Description

A DIN 11851 Coupling Nut is a critical component used in fluid handling systems, particularly within industries such as food and beverage, dairy, and pharmaceuticals, where maintaining sanitary connections is essential. This nut is designed to secure the male and female parts of a DIN 11851 coupling, ensuring a tight, leak-proof connection that is easy to assemble and disassemble for cleaning and maintenance.

Constructed from high-quality stainless steel, the DIN 11851 Coupling Nut offers excellent durability, corrosion resistance, and ease of cleaning. Stainless steel is the preferred material in these industries due to its ability to withstand frequent cleaning, exposure to chemicals, and high temperatures without compromising the integrity of the connection. This makes it ideal for environments where hygiene and long-term reliability are paramount.

The nut is internally threaded and is designed to mate with the external threads of the male DIN 11851 coupling. When the nut is tightened, it draws the male and female coupling components together, compressing the seal between them to create a secure, sanitary connection. This tight seal is crucial in preventing leaks and maintaining the purity of the fluid being transferred, which is vital in industries where contamination could compromise product quality and safety.

One of the key advantages of the DIN 11851 Coupling Nut is its ease of use. It can be easily tightened or loosened by hand or with the use of a spanner, making it convenient for quick assembly and disassembly. This feature is particularly important in sanitary applications where connections need to be regularly cleaned and inspected to ensure they remain free from contaminants.

Specifications

Specifications

-

ProductDIN 11851

-

TypeDIN 11851 Adaptor

-

Connection 1

-

Material Type

-

Colour

Features & Benefits

Features & Benefits

Application

Application

Payment & Security

How to Order with JML Henderson Ltd

JML Henderson operates on a quotation-based ordering process to ensure every order is correctly specified and supplied.

Browse our website and submit a request for quotation for the products or hose assemblies you require. If you’re unsure what you need, our team is always happy to help, simply give us a call or send us an email.

Once your enquiry is received, our experienced team will review your requirements and provide a tailored quotation. When you’re happy to proceed, we’ll issue a proforma invoice for payment.

Payment can be made securely by bank transfer or card. As soon as payment is received, your order is released for immediate processing and dispatch.

Secure Payments

All payments are processed through secure payment systems. JML Henderson Ltd does not store or retain access to any card or payment details.