In the food processing industry, maintaining hygiene and safety is a top priority. Ensuring that all equipment and tools used in the production process meet rigorous safety standards is essential to prevent contamination and ensure that food products are safe for consumption. One of the critical components in food processing plants are industrial food-safe hoses, which play a crucial role in transferring liquids and solids in a safe and efficient manner.

What Are Industrial Food-Safe Hoses?

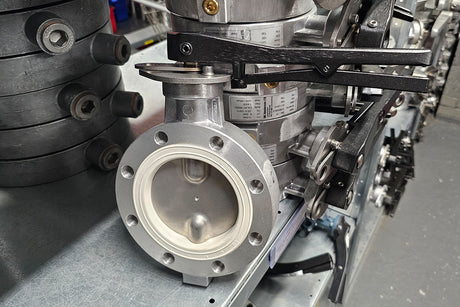

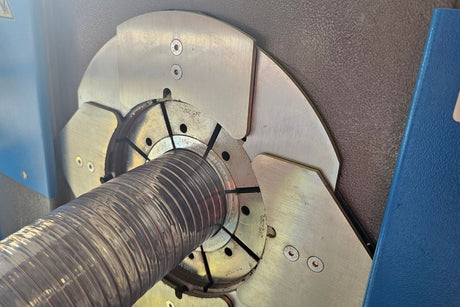

Industrial food-safe hoses are specially designed tubing used in food processing facilities to transport materials such as food, beverages, and pharmaceuticals. These hoses are made from high-quality materials that are resistant to chemicals, abrasion, and extreme temperatures, ensuring that they can handle the demands of the food processing industry. The hoses are also designed to prevent the growth of bacteria and other microorganisms that could potentially contaminate the products being processed.

Why Are Food-Safe Hoses Important?

Food-safe hoses play a crucial role in the food processing industry for several reasons:

-

Hygiene and Safety: Food-safe hoses are designed to be easily cleaned and sanitized, preventing the buildup of bacteria and other contaminants. This is essential for maintaining a hygienic and safe production environment.

-

Versatility: These hoses are used for a wide range of applications, including transporting liquids, powders, and granulated materials. They can handle everything from milk and juices to powders and grains.

-

Durability: Industrial food-safe hoses are built to withstand the harsh conditions of a food processing facility, including high pressures, temperatures, and abrasive materials. They are also resistant to chemical and microbial degradation.

-

Regulatory Compliance: The use of food-safe hoses is mandated by food safety regulations worldwide. By using these hoses, food processing facilities can ensure that they are in compliance with local, national, and international safety standards.

Selecting the Right Food-Safe Hose

When choosing a food-safe hose for a particular application, several factors need to be considered:

-

Material: Food-safe hoses are available in various materials, including PVC, polyurethane, silicone, and rubber. The choice of material will depend on factors such as the temperature of the materials being transported, the required flexibility, and the resistance to chemicals and abrasion.

-

Temperature Range: It is important to select a hose that can handle the temperatures of the materials being transported. Some hoses are designed for high-temperature applications, while others are suitable for low-temperature use.

-

Pressure Rating: The pressure rating of the hose indicates the maximum pressure it can handle without failing. It is important to choose a hose with a pressure rating that is appropriate for the application.

-

Size: Hoses come in various sizes and lengths. The correct size will depend on the flow rate of the materials being transported, as well as the connections and equipment being used.

-

Certifications: Ensure that the hose has the necessary certifications, such as FDA or 3-A approval, to ensure that it is safe for food contact.

Conclusion

Industrial food-safe hoses play a crucial role in the food processing industry, ensuring that products are safe for consumption and meeting the stringent regulations that govern the industry. By selecting the right hose for the application, food processing facilities can ensure that their operations are efficient, hygienic, and safe.