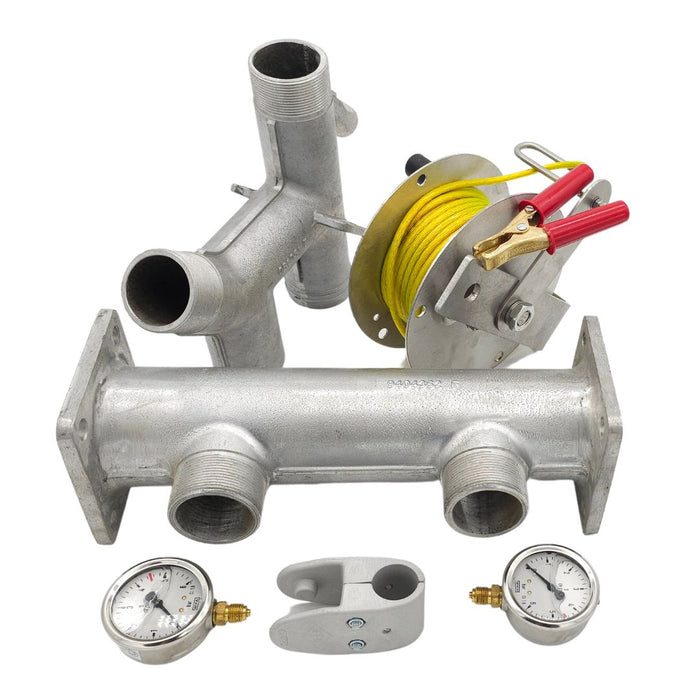

Europa Non Return Valve (Brass)

£0.01Unit price /Unavailable- £0.01Unit price /Unavailable

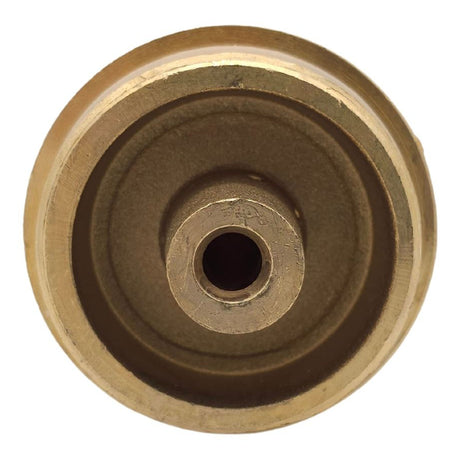

Brass Angle Non Return Valve Cap

£0.01Unit price /UnavailableMondeo Non Return Valve (Stainless Steel)

£0.01Unit price /Unavailable- £0.01Unit price /Unavailable

- £0.01Unit price /Unavailable

RITAG Wafer Type Non Return Valve (Brass)

£0.01Unit price /UnavailableBrass Angle Non Return Valve Plunger (Stainless Steel)

£0.01Unit price /UnavailableBrass Angle Non Return Valve Plunger

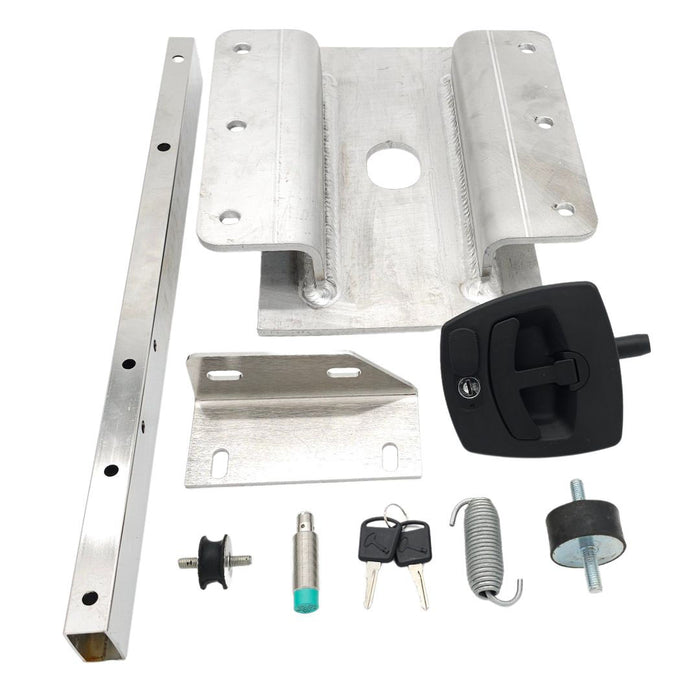

£0.01Unit price /UnavailableBrass Angle Non Return Valve Spring

£0.01Unit price /Unavailable- £0.01Unit price /Unavailable

- £0.01Unit price /Unavailable

RITAG Non Return Valve Graphite Gasket

£0.01Unit price /Unavailable- £0.01Unit price /Unavailable

BSP Swing Check Non Return Valve (Brass)

£0.01Unit price /UnavailableSteam Trap With Strainer BSP Threaded

£0.00Unit price /UnavailableMission Non Return Valve Dual Plate (Cast Iron)

£0.00Unit price /UnavailableSureneal Swing Check Non Return Valve

£0.00Unit price /UnavailableAngle Non Return Valve (Aluminium)

£0.00Unit price /Unavailable