Hose Fittings

Hose fittings are essential components that serve as the interface between hoses and the various equipment or systems to which they are connected. Made from materials like brass, stainless steel, or plastic, these fittings come in a wide array of shapes and sizes, including elbows, tees, and couplings, to suit the specific requirements of different applications.

- Featured

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old

FiltersFilter & Sort

BSP Male to Male 90deg Steel Bend

£0.00Unit price /Unavailable- £0.00Unit price /Unavailable

PN16 Flange Enlarger Hose Tail (Mild Steel)

£0.00Unit price /UnavailablePN16 Swivel Flange Enlarger Serrated Tail (Mild Steel)

£0.00Unit price /UnavailableBSP Barrel Nipple (Mild Steel)

£0.00Unit price /UnavailableWeld On Serrated Hose Tail (Mild Steel)

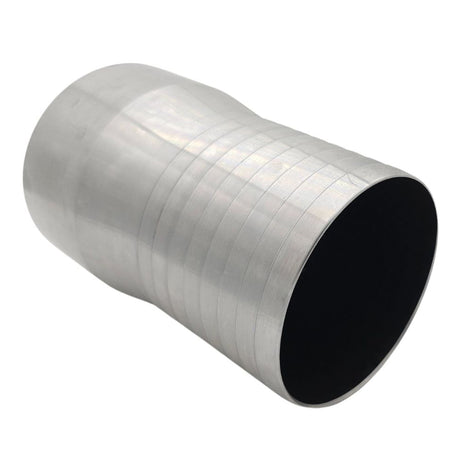

£0.00Unit price /UnavailableBSP Male Ribbed Hose Tail Long (Aluminium)

£0.00Unit price /UnavailableBSP Male Ribbed Hose Tail (Aluminium)

£0.00Unit price /Unavailable- £0.00Unit price /Unavailable

BSP Blank Cap (Stainless Steel)

£0.00Unit price /UnavailableBSP Female Serrated Hose Tail (Aluminium)

£0.00Unit price /UnavailableBSP Male to Female Extension (Stainless Steel)

£0.00Unit price /UnavailableBSP Female to Female 45° Elbow (Stainless Steel)

£0.00Unit price /UnavailableBSP Female to Female 90° Elbow (Stainless Steel)

£0.00Unit price /UnavailableBSP Male to Female 90° Elbow (Stainless Steel)

£0.00Unit price /Unavailable- £0.00Unit price /Unavailable

- £0.00Unit price /Unavailable

- £0.00Unit price /Unavailable

BSP Male to Male 45° Bend (Steel)

£0.00Unit price /Unavailable- £0.00Unit price /Unavailable

BSP Male to Male 90° Bend (Aluminium)

£0.00Unit price /Unavailable- £0.00Unit price /Unavailable

- £0.00Unit price /Unavailable

BSP Male to Male Adaptor (Aluminium)

£0.01Unit price /UnavailableBSP Male to Female Adaptor (Aluminium)

£0.01Unit price /UnavailableBSP Male to BSP Female Reducer (Aluminium)

£0.01Unit price /UnavailableBSP Female to Female Reducer (Aluminium)

£0.01Unit price /UnavailableBSP Female to BSP Male Reducer (Aluminium)

£0.01Unit price /Unavailable

Interested in a Quote?

Industrial Hoses

Industrial hoses are robust, flexible tubes designed to convey fluids, gases, or granular materials under varying conditions and pressures. These hoses are employed across a diverse range of industries, including petrochemical, food processing, construction, and manufacturing, to name just a few. Made from materials such as rubber, PVC, or metal, they can be reinforced with layers of textile, wire, or other synthetic materials for added strength and durability.

Hose Clips & Clamps

Hose clips and clamps are mechanical devices specifically designed to secure hoses onto fittings, thereby preventing unwanted fluid leakage or detachment. These components are vital in various applications, such as automotive systems, industrial machinery, and plumbing. Made from materials like stainless steel, plastic, or even heavy-duty rubber, hose clips and clamps can range from simple wire forms to more elaborate quick-release or adjustable types.

Shop our Catalogue

- Hoses

- Clips & Clamps

- Couplings & Fittings

- Tanker Parts

- Industrial Hoses

- Ducting

- PVC Hoses

- Hose Accessories

- Hose Manufacturers

- Clips & Clamps

- Clamp Material

- Manufacturer

- Couplings

- Fittings

- Hose Carriers

- Valves

- Aeration & Filters

- Bowls, Outlet & Discharge

- Tanker Body Parts

- Chassis Body Parts

- Engine Parts

-

Bulk Material Hoses

Bulk Material Hoses

-

Food Safe Hoses

Food Safe Hoses

-

Silo Vehicle Hoses

Silo Vehicle Hoses

-

Water & Liquid Hoses

Water & Liquid Hoses

-

Automotive Hoses

Automotive Hoses

-

Composite Hoses

Composite Hoses

-

Agricultural Hoses

Agricultural Hoses

-

Stainless Steel Hoses

Stainless Steel Hoses

-

Abrasion Resistant (PU) Ducting

Abrasion Resistant (PU) Ducting

-

Anti-static Ducting

Anti-static Ducting

-

Food & Pharma Ducting

Food & Pharma Ducting

-

High Temperature Ducting

High Temperature Ducting

-

Ventilation Ducting

Ventilation Ducting

-

Suction & Delivery Hoses

Suction & Delivery Hoses

-

Wire Reinforced Hoses

Wire Reinforced Hoses

-

Braided & Tubing Hoses

Braided & Tubing Hoses

-

Layflat Hoses

Layflat Hoses

-

Whipcheck Safety Cables

Whipcheck Safety Cables

-

Anti-Scuff

Anti-Scuff

-

ID Tags

ID Tags

-

Alfagomma

Alfagomma

-

Griflex

Griflex

-

IVG

IVG

-

Thor

Thor

-

Trelleborg

Trelleborg

-

Copely

Copely

-

Continental

Continental

-

Gollmer & Hummel

Gollmer & Hummel

-

Masterflex

Masterflex

-

Band-it

Band-it

-

Constant Tension Clamps

Constant Tension Clamps

-

Ear 'O' Clips

Ear 'O' Clips

-

P-Clips

P-Clips

-

T Bolt Clamps

T Bolt Clamps

-

T Screw Clamps

T Screw Clamps

-

Worm Drive Clamps

Worm Drive Clamps

-

Safety Clamps

Safety Clamps

-

W1 - Mild Steel

W1 - Mild Steel

-

W2 - Part Stainless (430)

W2 - Part Stainless (430)

-

W3 - Full Stainless (430)

W3 - Full Stainless (430)

-

W4 - Full Stainless (304)

W4 - Full Stainless (304)

-

W5 - Full Stainless (316)

W5 - Full Stainless (316)

-

Mikalor

Mikalor

-

JCS

JCS

-

Norma

Norma

-

Unicone Couplings

Unicone Couplings

-

Bauer Couplings

Bauer Couplings

-

BSP Couplings

BSP Couplings

-

Camlock Couplings

Camlock Couplings

-

Geka Couplings

Geka Couplings

-

Guillemin Couplings

Guillemin Couplings

-

Instantaneous Couplings

Instantaneous Couplings

-

Lever Lock Couplings

Lever Lock Couplings

-

RJT Couplings

RJT Couplings

-

DIN 11851 Couplings

DIN 11851 Couplings

-

SMS Couplings

SMS Couplings

-

Storz Couplings

Storz Couplings

-

Tank Wagon Couplings

Tank Wagon Couplings

-

Toggle Couplings

Toggle Couplings

-

URT Couplings

URT Couplings

-

Wilcox Couplings

Wilcox Couplings

-

Aluminium Fittings

Aluminium Fittings

-

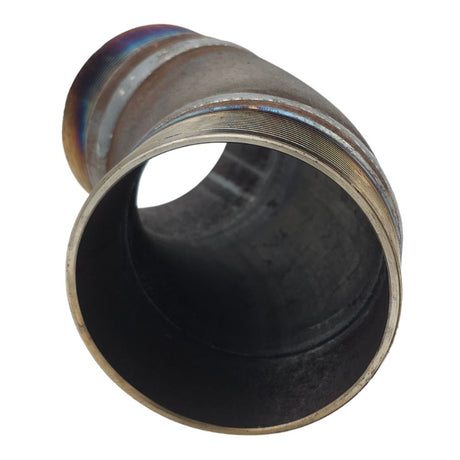

Mild Steel Fittings

Mild Steel Fittings

-

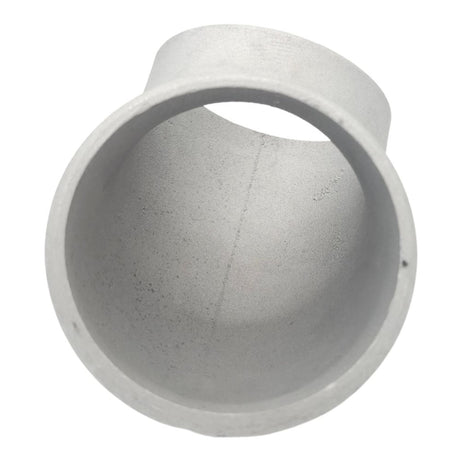

Polypropylene Fittings

Polypropylene Fittings

-

Stainless Steel Fittings

Stainless Steel Fittings

-

Hose Carriers

Hose Carriers

-

Hose Carrier Brackets

Hose Carrier Brackets

-

Hose Carrier Locks

Hose Carrier Locks

-

Hose Carrier Keys

Hose Carrier Keys

-

Hose Carrier Accessories

Hose Carrier Accessories

-

Air Shut Off Valves

Air Shut Off Valves

-

Ball Valves & Accelerators

Ball Valves & Accelerators

-

Butterfly Valves

Butterfly Valves

-

Diaphragm Valves

Diaphragm Valves

-

Gate Valves

Gate Valves

-

Non Return Valves

Non Return Valves

-

Pinch Valves

Pinch Valves

-

Pressure Relief Valves

Pressure Relief Valves

-

Universal Joints

Universal Joints

-

Aeration Pads

Aeration Pads

-

Aeration Socks

Aeration Socks

-

Aeration Valves

Aeration Valves

-

Air Filters

Air Filters

-

Compressor Filters

Compressor Filters

-

Vent Silencers

Vent Silencers

-

Discharge Elbows

Discharge Elbows

-

Discharge Bowl Flange

Discharge Bowl Flange

-

Drain Pots & Outlet Connection

Drain Pots & Outlet Connection

-

Flanges

Flanges

-

Manlid & Accessories

Manlid & Accessories

-

Material Line

Material Line

-

Sight Glasses

Sight Glasses

-

Accessories

Accessories

-

Air Manifold

Air Manifold

-

Anti Static & Earthing

Anti Static & Earthing

-

Gas Struts & Pneumatic Cylinders

Gas Struts & Pneumatic Cylinders

-

Gauges & Thermometers

Gauges & Thermometers

-

Handrail & Catwalk Parts

Handrail & Catwalk Parts

-

Information Holders

Information Holders

-

Lighting & Electronics

Lighting & Electronics

-

Load Security

Load Security

-

Locks & Catches

Locks & Catches

-

Sensors

Sensors

-

Air Tanks

Air Tanks

-

Axle Catch Ropes

Axle Catch Ropes

-

Bumpers, Brackets & LED

Bumpers, Brackets & LED

-

Landing Leg Brackets

Landing Leg Brackets

-

Mudguards & Brackets

Mudguards & Brackets

-

Side Guards

Side Guards

-

Tool Boxes

Tool Boxes

-

Air Filter Indicators

Air Filter Indicators

-

Control Panel

Control Panel

-

Drive Couplings & Clutches

Drive Couplings & Clutches

-

Electric Tip

Electric Tip

-

Engine Mountings

Engine Mountings

-

Fuel Tanks

Fuel Tanks

-

Hand Throttle

Hand Throttle

-

JCB & Yanmar

JCB & Yanmar

-

PTO / Hydraulic

PTO / Hydraulic

Hose fittings are crucial components used to connect hoses in various systems, facilitating the secure and efficient transfer of fluids, gases, and sometimes even solid materials. Here are some benefits of using hose fittings:

Improved Functionality

-

Secure Connections: High-quality fittings ensure that hoses are securely connected, minimizing leaks and enhancing the overall efficiency of a system.

-

Versatility: Fittings allow for easy adaptation of hoses to various sizes and shapes of ports, enabling a wide range of applications.

-

Orientation: Certain types of fittings can be swiveled or angled to provide optimal orientation, making it easier to navigate complex routing or tight spaces.

Safety Benefits

-

Reduced Hazards: Secure and proper fittings reduce the risk of leaks or bursts, which could otherwise lead to hazardous conditions, including slips, falls, or exposure to dangerous substances.

-

Pressure Management: Some fittings come with safety features for pressure regulation, ensuring that the hose operates within safe pressure limits.

-

Quick Disconnect: Many fittings offer quick-disconnect features, allowing for rapid and safe hose changes, particularly important in emergency situations or frequent change-over applications.

Ease of Use

-

Ease of Assembly: Many modern fittings are designed for easy assembly and disassembly, reducing the need for specialized tools or training.

-

Reusable: Some high-quality fittings are reusable, offering cost advantages and environmental benefits.

-

Quick Identification: Fittings often come with markings or color codes that make it easier to identify their size, material, and compatibility, simplifying maintenance and repairs.

Durability and Reliability

-

Material Options: Fittings are available in a variety of materials, including brass, stainless steel, and plastic, each offering different levels of corrosion resistance, durability, and chemical compatibility.

-

High-Quality Seals: Many fittings come with built-in seals (O-rings, gaskets, etc.) that provide an extra layer of security against leaks.

-

Longevity: Quality hose fittings can significantly extend the life of a hose by providing secure and durable connections.

Cost-Effectiveness

-

Reduced Maintenance: Reliable fittings require less frequent replacements and lower maintenance costs.

-

Increased Efficiency: Proper fittings ensure a more efficient system by minimizing leaks and pressure losses, thereby reducing operational costs.

Customization and Compatibility

-

Custom Solutions: Fittings can be custom-designed to meet specific requirements, offering solutions for unique applications or challenging environments.

-

Interchangeability: Standardized fittings allow for easier interchangeability between different hoses and systems, offering greater flexibility.

Environmental Benefits

-

Resource Conservation: Secure fittings can minimize leaks, helping to conserve valuable resources like water, fuel, or chemicals.

-

Lower Emissions: By preventing gas leaks, certain types of fittings contribute to lower emissions, aiding in environmental protection.

When selecting hose fittings, it’s crucial to consider factors such as material compatibility, pressure ratings, and the specific requirements of your application to ensure you choose the most suitable options. Always adhere to manufacturer recommendations and industry standards for maximum safety and efficiency.

Subscribe to our emails

Be the first to know about our new products including hoses, couplings, clips, clamps & tanker parts.