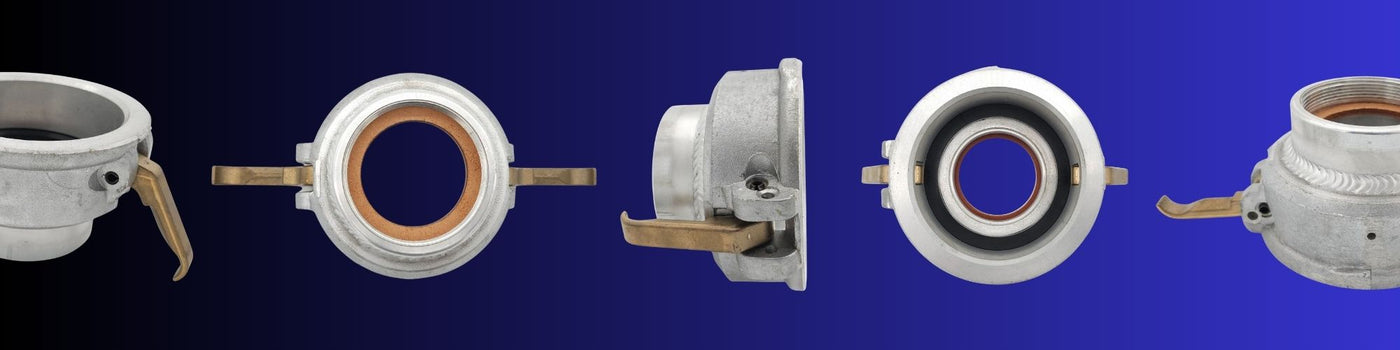

Camlock Coupling Part A Male to BSP Female (Aluminium)

£0.01Unit price /UnavailableCamlock Coupling Part B Female to BSP Male (Aluminium)

£0.01Unit price /UnavailableCamlock Coupling Part C Female (Aluminium)

£0.01Unit price /UnavailableCamlock Coupling Part D Female to BSP Female (Aluminium)

£0.01Unit price /UnavailableCamlock Coupling Part DC Blank Cap (Aluminium)

£0.01Unit price /UnavailableCamlock Coupling Part DP Blank Plug (Aluminium)

£0.01Unit price /UnavailableCamlock Coupling Part E Male Hose Tail (Aluminium)

£0.01Unit price /UnavailableCamlock Coupling Part F Male to BSP Male (Aluminium)

£0.01Unit price /UnavailableCamlock Coupling Male to BSP Female Reducer (Aluminium)

£0.01Unit price /UnavailableCamlock Coupling Female to BSP Male Reducer (Aluminium)

£0.01Unit price /UnavailableCamlock Coupling Female to BSP Female Reducer (Aluminium)

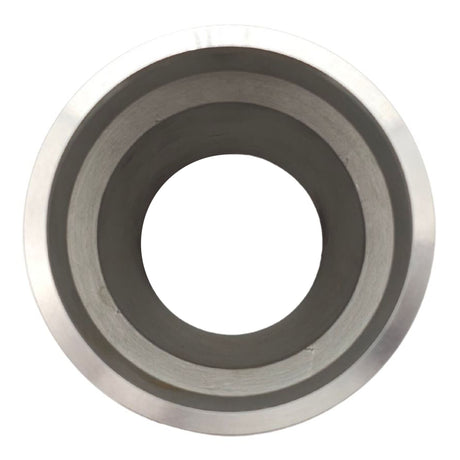

£0.01Unit price /UnavailableCamlock Coupling Replacement Arm (Stainless Steel)

£0.01Unit price /Unavailable- £0.01Unit price /Unavailable

Camlock Coupling Part C Female Reducing Hose Tail

£0.00Unit price /UnavailableCamlock Coupling Part B Female Lockable to Reducing BSP Male (Aluminium)

£0.00Unit price /UnavailableCamlock Coupling Part A Male to BSP Female Lugged & Seated (Aluminium)

£0.00Unit price /UnavailableCamlock Coupling Part C Female (Stainless Steel)

£0.00Unit price /UnavailableCamlock Coupling Part A Male to BSP Female (Stainless Steel)

£0.00Unit price /UnavailableCamlock Coupling Part E Male (Stainless Steel)

£0.00Unit price /UnavailableCamlock Coupling Part B Female to BSP Male (Polypropylene)

£0.00Unit price /UnavailableCamlock Coupling Part C Female (Polypropylene)

£0.00Unit price /UnavailableCamlock Coupling Part E (Polypropylene)

£0.00Unit price /UnavailableCamlock Coupling Part F Male to BSP Male (Polypropylene)

£0.00Unit price /UnavailableCamlock Coupling Part A Male to BSP Female (Polypropylene)

£0.00Unit price /UnavailableCamlock Coupling Part D Female to BSP Female (Polyproplene)

£0.00Unit price /UnavailableCamlock Coupling Part DC Blank Cap (Polypropylene)

£0.00Unit price /UnavailableCamlock Coupling Part DP Blank Plug (Polypropylene)

£0.00Unit price /UnavailableGrey Composite Hose Assembly with Camlock Females

£0.00Unit price /Unavailable