Unicone Coupling Serrated Tail (Stainless Steel)

£0.01Unit price /UnavailableCamlock Coupling Part E Male Hose Tail (Aluminium)

£0.01Unit price /UnavailableWilcox Coupling Male Serrated Hose Tail (Gunmetal)

£0.01Unit price /UnavailableStorz Coupling to BSP Female Swivel (Stainless Steel)

£0.01Unit price /UnavailableTank Wagon Coupling Male VK (Brass)

£0.01Unit price /UnavailableToggle Hose Coupling Male with Two Clamps

£0.01Unit price /UnavailableWilcox Coupling Female Serrated Hose Tail (Aluminium)

£0.01Unit price /Unavailable- £0.01Unit price /Unavailable

- £0.01Unit price /Unavailable

- £0.01Unit price /Unavailable

- £0.01Unit price /Unavailable

- £0.01Unit price /Unavailable

URT Male Weld Stub (Stainless Steel)

£0.01Unit price /UnavailableCamlock Coupling Part D Female to BSP Female (Aluminium)

£0.01Unit price /Unavailable- £0.01Unit price /Unavailable

URT Coupling Male to Female Reducer (Plastic)

£0.01Unit price /UnavailableURT Coupling Male Smooth Hose Tail (Steel)

£0.01Unit price /Unavailable- £0.01Unit price /Unavailable

URT Coupling Female to BSP Female (Stainless Steel)

£0.01Unit price /UnavailableURT Coupling Female Reducing Hose Tail (Aluminium)

£0.01Unit price /Unavailable- £0.01Unit price /Unavailable

URT Blank Cap (Stainless Steel)

£0.01Unit price /Unavailable- £0.01Unit price /Unavailable

Camlock Coupling Replacement Arm (Stainless Steel)

£0.01Unit price /UnavailableCamlock Coupling Male to BSP Female Reducer (Aluminium)

£0.01Unit price /UnavailableCamlock Coupling Female to BSP Male Reducer (Aluminium)

£0.01Unit price /UnavailableCamlock Coupling Female to BSP Female Reducer (Aluminium)

£0.01Unit price /Unavailable- £0.01Unit price /Unavailable

Wilcox Coupling Male Weld Stub (Aluminium)

£0.01Unit price /UnavailableWilcox Coupling Male to BSP Female (Gunmetal)

£0.01Unit price /UnavailableWilcox Coupling Male Spool (Stainless Steel)

£0.01Unit price /UnavailableWilcox Coupling Female Swivel To BSP Male (Stainless Steel)

£0.01Unit price /UnavailableWilcox Coupling Female Swivel To BSP Female (Gunmetal)

£0.01Unit price /UnavailableWilcox Coupling Female Serrated Hose Tail (Stainless Steel)

£0.01Unit price /UnavailableStorz Coupling to BSP Male (Aluminium)

£0.01Unit price /UnavailableStorz Coupling to BSP Female Swivel Lockable (Aluminium)

£0.01Unit price /UnavailableStorz Coupling to BSP Female Swivel (Aluminium)

£0.01Unit price /UnavailableStorz Coupling to BSP Female Lockable (Aluminium)

£0.01Unit price /UnavailableStorz Coupling to BSP Female (Stainless Steel)

£0.01Unit price /UnavailableStorz Coupling to BSP Female (Aluminium)

£0.01Unit price /UnavailableStorz Coupling Safety Strap 133 To 89 (Mild Steel)

£0.01Unit price /UnavailableStorz Coupling Spanner 100mm-150mm

£0.01Unit price /UnavailableStorz Coupling Segmented Binding Tail Set (Aluminium)

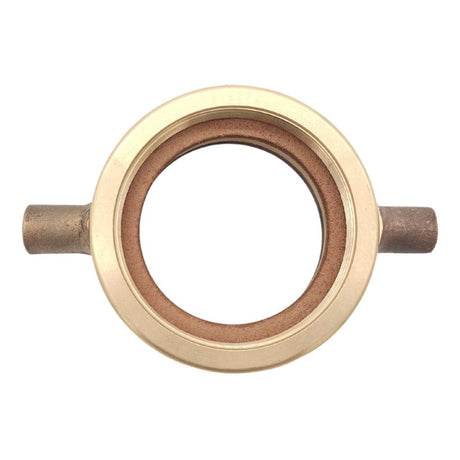

£0.01Unit price /UnavailableStorz Coupling Seal (White Rubber)

£0.01Unit price /UnavailableStorz Coupling Seal (Silicone)

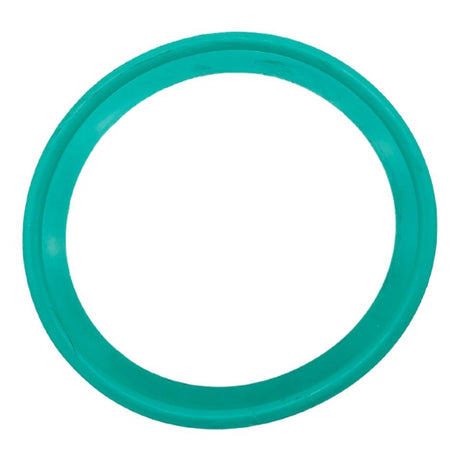

£0.01Unit price /UnavailableStorz Coupling Seal (Green Viton)

£0.01Unit price /UnavailableStorz Coupling Safety Strap (Rubber Lined)

£0.01Unit price /UnavailableStorz Coupling Safety Strap (Stainless Steel)

£0.01Unit price /UnavailableStorz Coupling Safety Strap (Mild Steel)

£0.01Unit price /UnavailableStorz Coupling Reducer (Aluminium)

£0.01Unit price /Unavailable