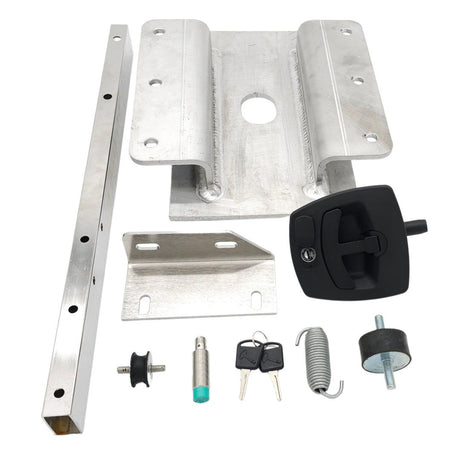

Plastic Wear Bracket

If you prefer to speak to someone directly, you can reach us via phone during our business hours. Simply dial 01406 362978, and one of our knowledgeable representatives will be ready to assist you.

Alternatively you can send us your query or request to sales@jmlhenderson.co.uk, and we will respond to you as promptly as possible.

Plastic wear brackets are typically used to provide support and reduce friction or wear in various applications, including industrial equipment, automotive components, and machinery. These brackets are often made of durable and wear-resistant plastic materials like nylon, UHMW (Ultra-High Molecular Weight Polyethylene), or PTFE (Polytetrafluoroethylene).

Key Features:

-

Durability: Made of high-quality plastic materials, these brackets resist wear and tear, even under heavy loads and frequent use.

-

Reduced Friction: The low-friction properties of the plastic help minimize wear on both the bracket and the components it interacts with, extending the lifespan of the equipment.

-

Corrosion Resistance: Unlike metal brackets, plastic wear brackets are immune to rust and corrosion, making them suitable for use in harsh environments.

-

Lightweight: Plastic brackets are typically lighter than their metal counterparts, reducing the overall weight of the equipment and improving efficiency.

-

Easy Installation: Plastic wear brackets are easy to install, requiring minimal tools and time.

-

Cost-Effective: Due to their durability and low maintenance requirements, plastic wear brackets offer a cost-effective solution for wear protection and support.

-

Customizability: Plastic wear brackets can be customized in terms of size, shape, material, and other specifications to fit specific applications and requirements.

-

Noise Reduction: Plastic brackets can help reduce noise generated by moving parts in machinery and equipment.

-

Thermal Insulation: Plastic wear brackets provide better thermal insulation compared to metal brackets, reducing heat transfer and preventing overheating of components.

-

Chemical Resistance: Many plastic materials used for wear brackets are resistant to a wide range of chemicals, making them suitable for use in industries where exposure to corrosive substances is common.

Plastic wear brackets are a versatile and reliable solution for various applications requiring support, wear protection, and reduced friction. Their durability, low maintenance requirements, and customizability make them an excellent choice for industries ranging from automotive and aerospace to food processing and material handling.

-

ProductUniversal Joints

-

TypeBrackets

- Plastic Wear Bracket